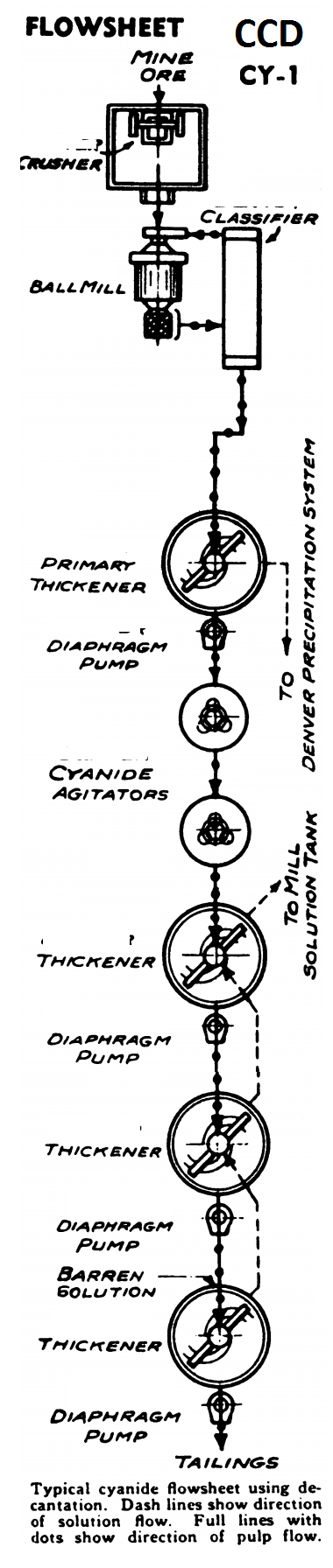

The Process Flowsheet CCD CY-1 shows (below) the continuous counter-current decantation system, in which all the ore is first reduced to a very fine state in the grinding mill-classifier circuit, in a cyanide solution. The slime overflow of the classifier, usually 70%—200 mesh, or finer, is sent to the first thickener, known as the primary thickener.

Here the pregnant solution, containing a large part of the dissolved gold and silver values, overflows from the top of the thickener and is sent to a clarifier. then to the precipitating system where the gold and silver values are precipitated, the precipitate periodically being reduced to bullion in a furnace.

The underflow pulp of the primary thickener, containing the remaining values and usually at a pulp ratio of 1:1, is elevated by a diaphragm pump into a series of agitators. The agitators are used to aid in the dissolution of the remaining values, augmented by the introduction of air. The time of treatment required depends upon the values still remaining in the slimes or fine sands in the mill pulps.

From the agitators, the pulp at a density of approximately 1:1 overflows directly into the first of a series of secondary thickeners. This feed pulp is diluted with the overflow solution from the second of the secondary thickeners, which solution has been enriched by the removal of values from the second and third secondary thickeners. After the solution is intimately mixed with the pulp it enters the thickener feed well, rises to the top of the thickener, is overflowed and is pumped to either the mill solution tank or introduced into the precipitation system. The thickened pulp from the first of the secondary thickeners settles to the bottom, is raked to the center discharge, and is then pumped to the second secondary thickener where it is mixed with the overflow solution from the third of the secondary thickeners. Thus the pulp flows in one direction with gradually decreasing values, while the solution is pumped in the opposite direction with gradually increasing values, from a barren wash water to a sufficiently enriched solution suitable for precipitation or mill solution storage.

In this way the pulp is gradually lowered in value and the solution is gradually increased. The solution from the first of the series of secondary thickeners is either partly precipitated or sent to the mill solution tank to be used in the head of the mill circuit. This counter-current decantation system, as shown on Flowsheet No. CCD CY-1 is ideal for a large number of ores and is the ultimate in simplicity.

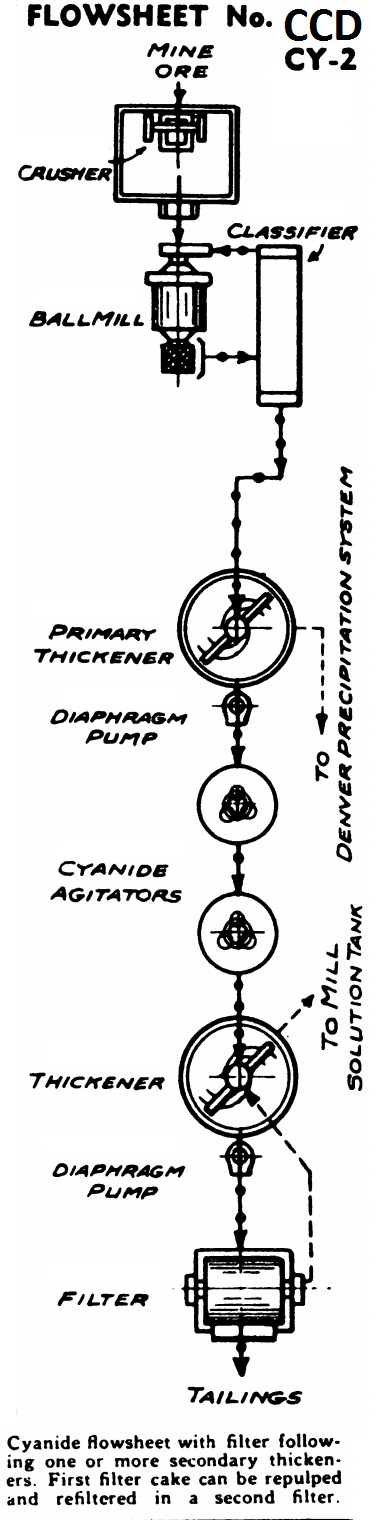

Circuit FLOWSHEET NO. CCD CY-2 is practically the same as Flowsheet No. CCD CY-1, only in place of the last two secondary thickeners a rotary filter is used. On some ores two or more thickeners are used between the agitators and the filter. There is no question about the lower soluble loss when using a filter but the cost of the filter operation, amounting to from 8c to 10c per ton, is an important item as compared to the low cost of operating thickeners. Therefore, the question as to whether a filter or a thickener is to be used at the tail end of the cyanide mill is a matter of economics, depending upon the housing facilities, initial investment in the plant, and operating cost. A tailing filter is necessary where water for milling is scarce, or where pollution of streams is prohibited.

https://www.911metallurgist.com/gold-leaching-plant-sale