Kaolin Ceramics

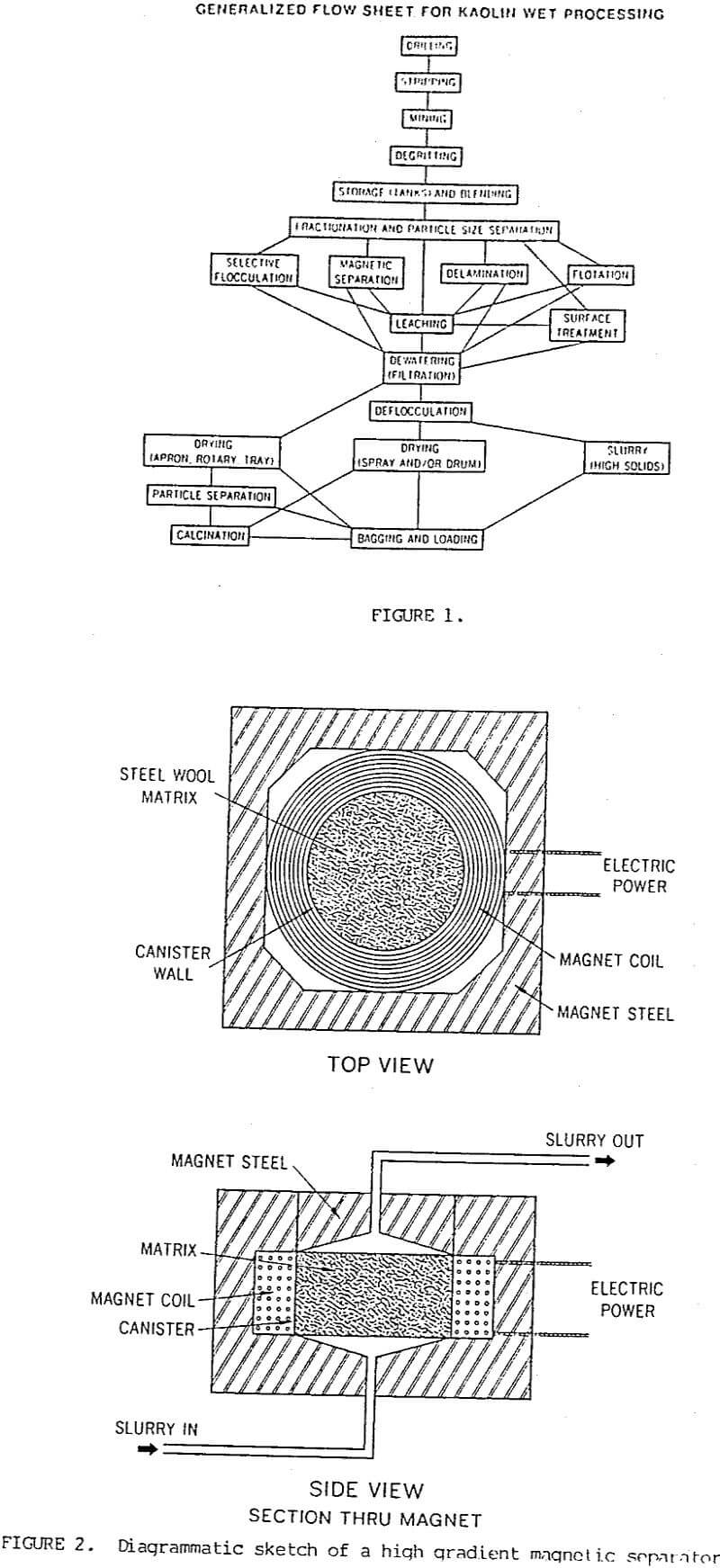

Kaolin is a clay comprised essentially of the mineral kaolinite which has the oxide composition of 46.3% SiO2, 39.8% Al2O3, and 13.9% combined H2O. The structural formula of kaolinite is (OH)8Si4Al4O10. These deposits are sedimentary and contain approximately 90% or more kaolinite along with minor quantities of quartz, mica, and smectite along with trace quantities […]

Silver Chloride Chemistry

To appreciate the development of industrial silver chloride processing it is helpful to outline some of its general properties. Since more comprehensive reviews are available, only basic concepts will be covered here. Silver chloride is a white, curdy, crystalline solid compound. In the lab, it is prepared from a solution of AgNO3 by precipitation with […]

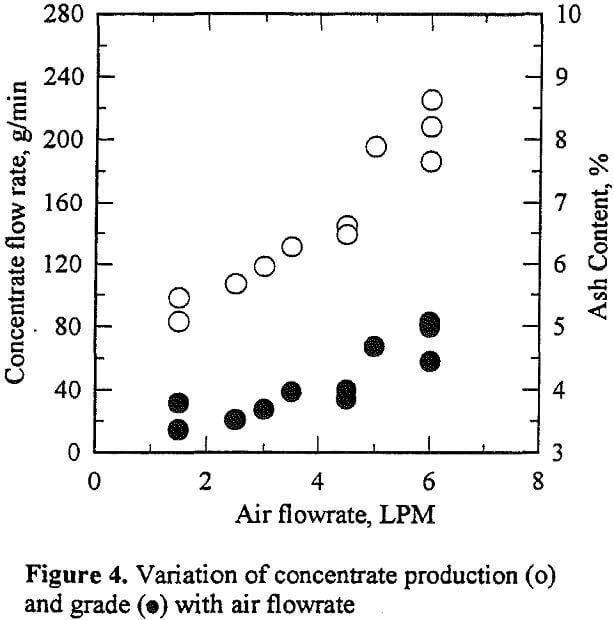

Effect of Air Flowrate on Flotation Column

On a flotation column cell, the variation of concentrate flowrate, clean coal yield and product grade with air flow rate are shown in Figure 4. These tests were carried out using a 5 wt. % feed slurry. The results show that the concentrate flow rate, yield and product ash content increased with air flow rate. […]

Visman’ General Sampling Theory

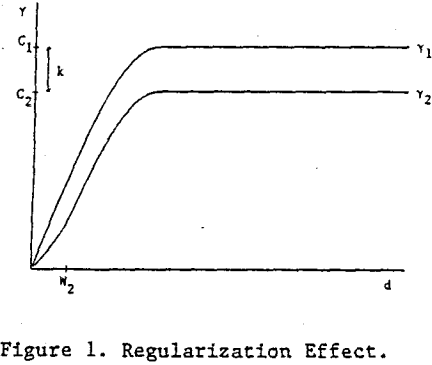

A comprehensive analysis of the entire range of related studies would require a lengthy discussion. Instead, this paper will focus only on the work of Visman (1962, 1969), because his work is part of the current ASTM D2234 standard on coal sampling (American Society for Testing and Materials, 1985). Visman’s work attempts to empirically determine […]

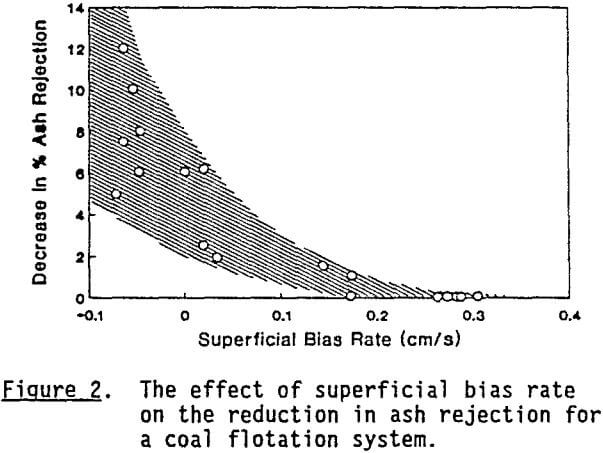

Column Flotation BIAS

Counter Current flow of mineralized bubbles & wash water The column underflow is always of slightly higher volume than the feed. This volume imbalance, called BIAS in the control system, is made up by wash water inserted at the top of the column. Part of this wash water travels down the column to exit with the […]

Gold Refining Contract

The operator’s relationship with the refinery depends entirely upon a well-defined written contract, good representation at the refinery and the use of reliable assay laboratories. While all contracts are similar in that they are meant to safeguard the interest of both refiner and miner, it is not unusual to find a single refinery writing a […]

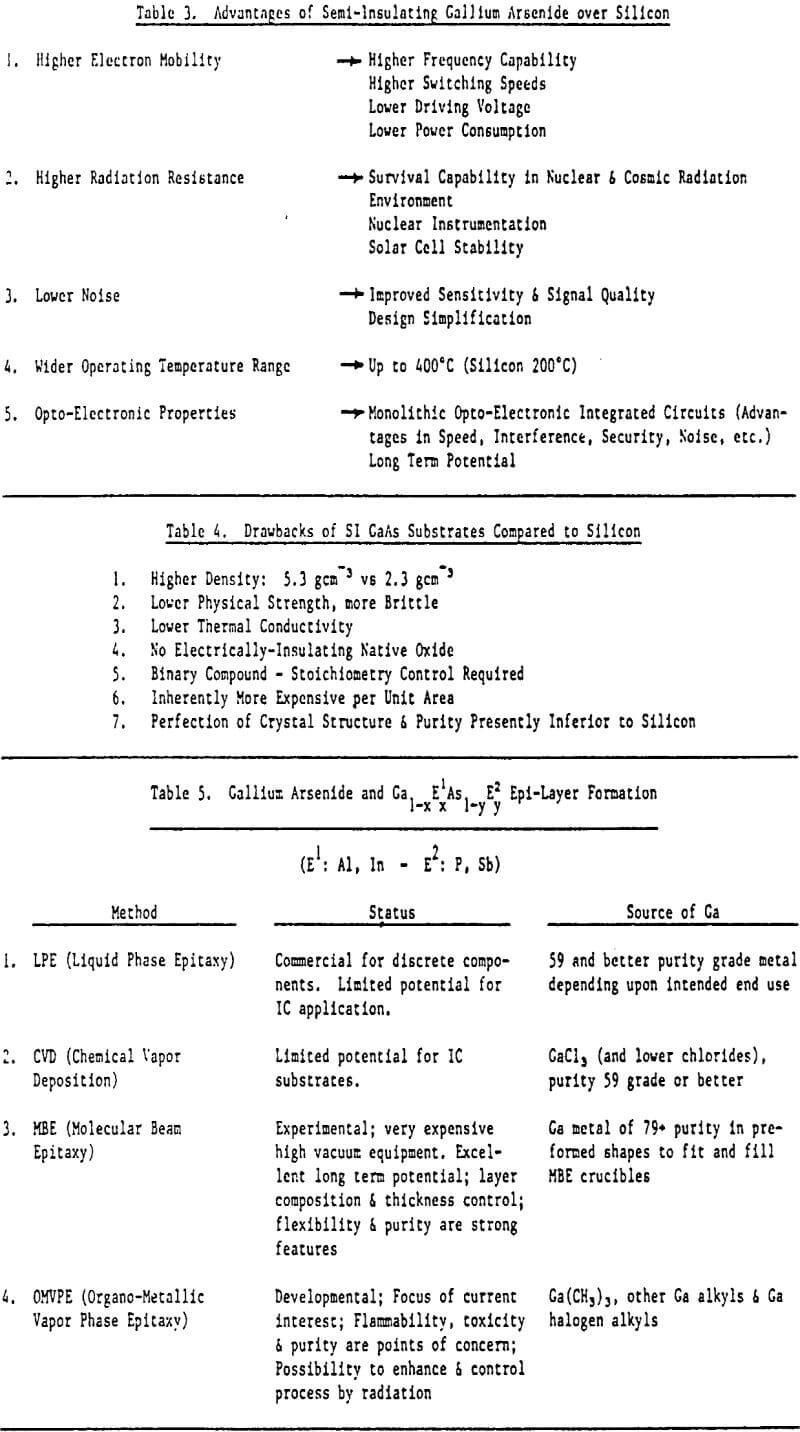

Gallium Uses

Gallium: Cominco has been at the interface between the semiconductor materials and the components industries since the commercialization of the transistor in the early fifties. Based on our commitment to R&D, we have become the largest merchant supplier of several specialty semiconductor substrates including LEC-grown semi-insulating gallium arsenide wafers on this continent. The following remarks are […]

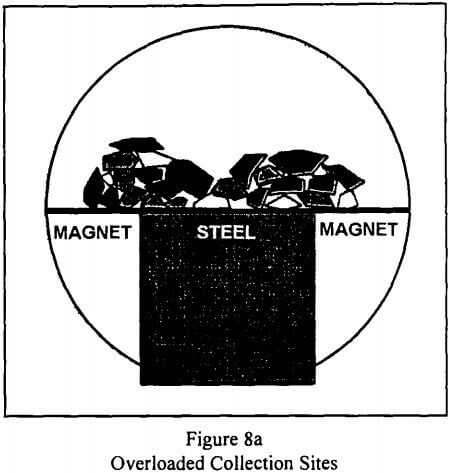

Heavy Minerals Sands Processing by Rare Earth Magnets

The first known attempts to apply a REM roll separator to a heavy mineral sands application were made in South Africa and Western Australia in 1985. At that time, an ilmenite beneficiation process, which was normally achieved with cross-belt separators, was tested with a full-size machine. The performance was not good because only a single […]

Dense Sludge Process

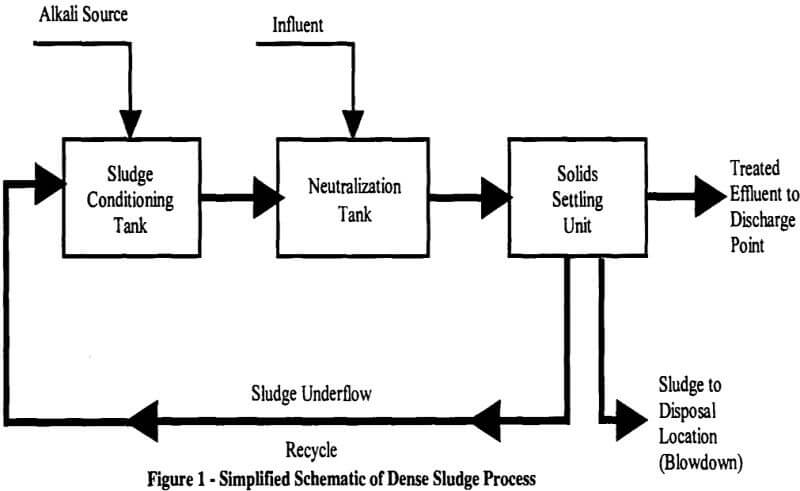

Figure 1 presents a simplified process flow diagram of the Dense Sludge process. The most significant change between Dense Sludge technology and conventional metals treatment is the method by which the alkali source is added. In conventional treatment systems, the alkali is added directly into the influent to achieve a desired pH setpoint. Generally, that […]

On-Stream Analysers Benefits

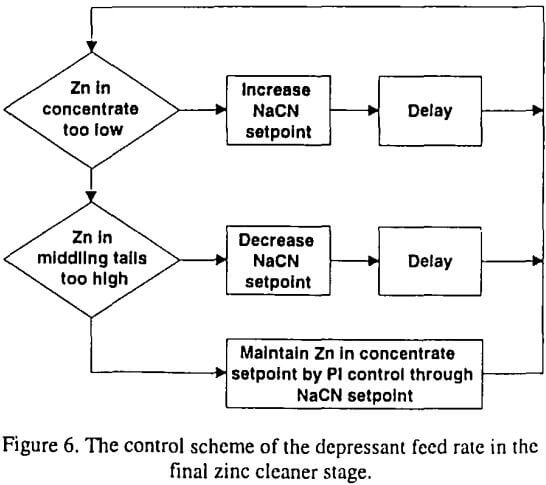

What are the benefits of having an OSA on-stream analyser? The assays are utilized for control in many ways, starting from individual control loops to overall optimization in the flotation circuits. Reagent dosages in the cleaner flotation stages are controlled by feedback from concentrate quality. For instance, the depressant in the zinc cleaner circuit is […]