Pulp Formulas & Metallurgical Formulas

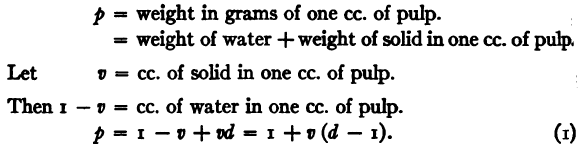

Definitions. “Pulp,” in flotation terminology, is a freely-flowing mixture of powdered ore and water. “Pulp density,” when the phrase is applied properly, indicates the specific gravity of the pulp. “Percentage of solids” means the ratio, expressed as a percentage, of the weight of the solids in a pulp to the total weight of pulp. “Pulp consistency” is the ratio, […]

Conical Mill Grinding Tests

In the laboratory work described in the following pages, a 4 ½-ft. Hardinge mill with three removable cylindrical sections, 16 in. each in length, was used. Fig. 1 shows the mill with three cylindrical rings in place. This combination allows a mill 4 ½ ft. by 0 in., 4 ½ ft. by 16 in., 4 ½ ft. […]

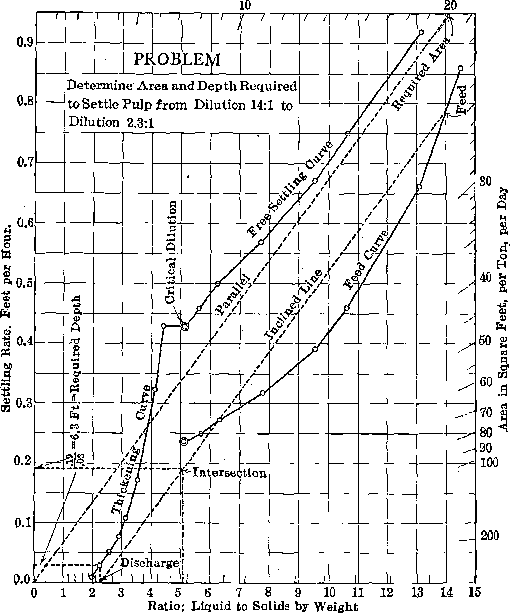

Calculate a Settling Tank’s Capacity – Thickener

During construction work at a mill, the metallurgical engineer in charge, ran a series of experiments on settling. His tests proved that deep settling tanks were not ordinarily necessary. The use of tanks 2 or 3 ft. in depth was suggested. Later experiments demonstrated that the following principles of settling applied to Tigre pulp. In settling dilute pulp, […]

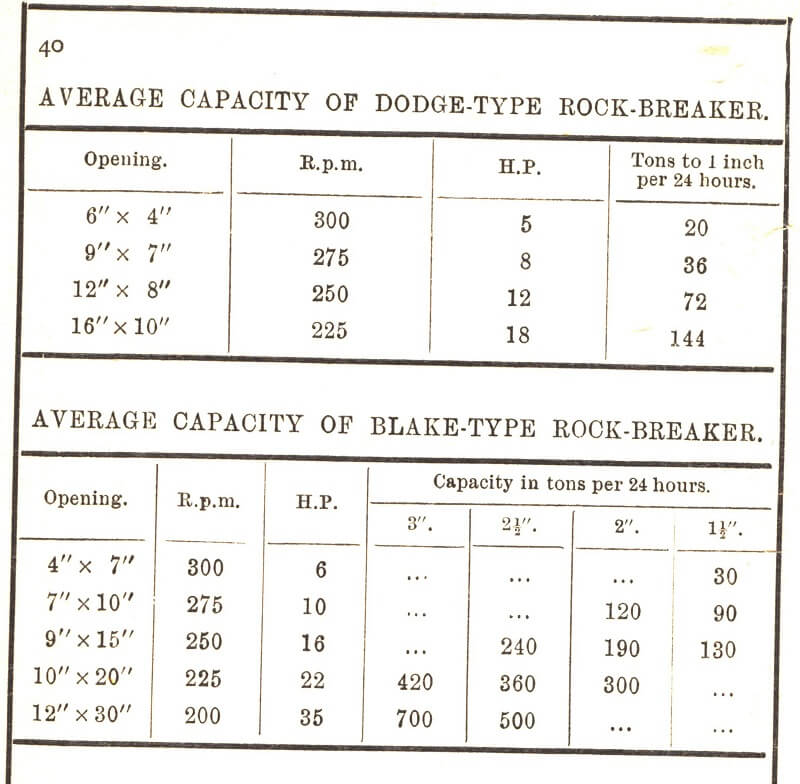

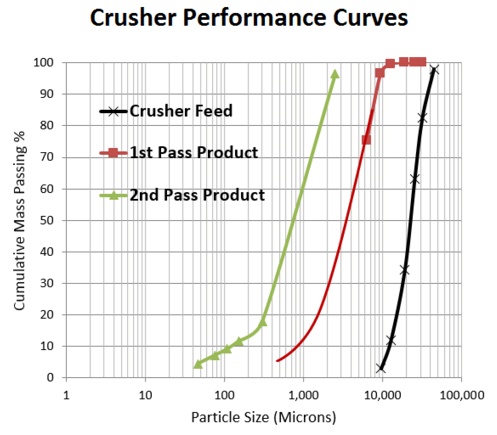

Small Jaw Crusher Capacity-Sizing Table

Massive, heavily reinforced, steel frame and bumper. Anti-friction roller bearings throughout. Side bearings sealed in carrier, permits removal of bumper without exposing bearings to dust and dirt. Jaw crushers are stock in most sizes. Sizes: 2¼” x 3½” through 40″ x 48″. https://www.911metallurgist.com/estimate-jaw-crusher-capacity

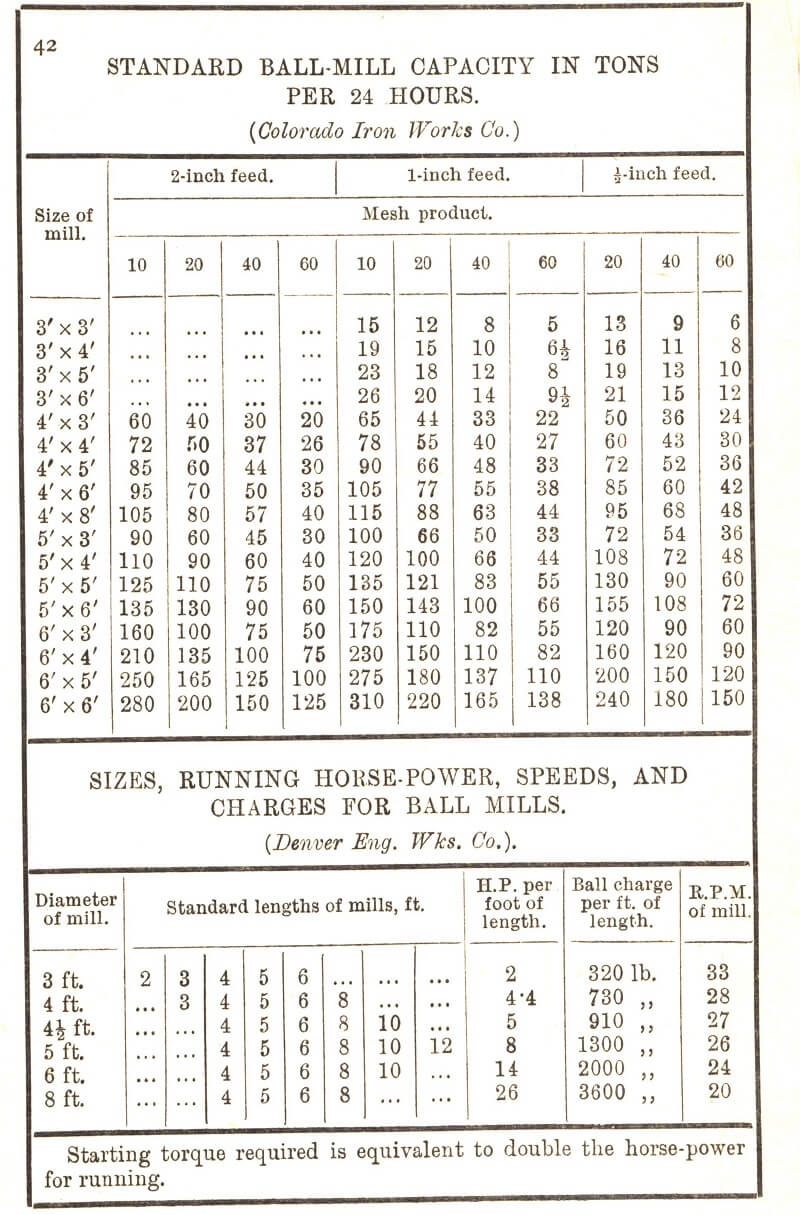

Small Ball Mill Capacity & Sizing Table

Do you need a quick estimation of a ball mill’s capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for tonnage a product P80 size? Use these 2 tables to get you close. No BWi Bond Work Index required here BUT be aware it is only […]

Hydrometallurgy Articles

Clean and efficient roasting solutions with Outotec’s cutting-edge technology Closed circuit precious metals extraction with recycled halogens Conventional or high capacity thickeners a better choice to make Correlating microstructure with simulated process parameters in MG high-pressure die-castings Critical Aspects of low grade ore benefication Detecting the direction of flow in liquid aluminum using an inverse […]

XRF for Better Plant Metallurgy Control

An un-monitored (un-assayed) tailing from a vibrating screen was exiting the system. Operators would eyeball the Zinc content from a handcut while true assays were only provided late the next day as part of the metallurgical material balance. Here I show 4 videos of the new step by step solution we implemented. It used a pizza […]

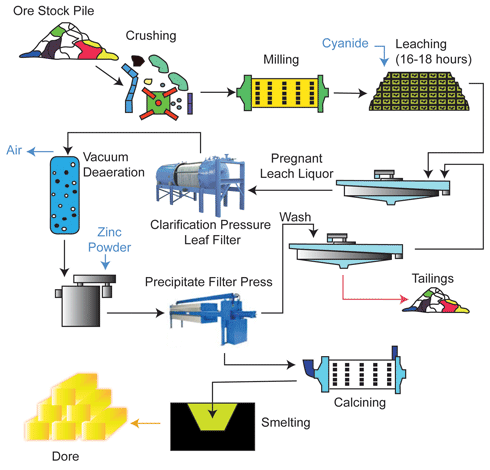

Gold Process Description

In our Gold Process Description EXAMPLE, the ore will be received by the crushing plant initially by rail haulage from the ABC Zone and later by truck from the DEF Zones. The 350 tonne live capacity coarse ore bin is sufficient for train or truck load surges and provides approximately five hours storage of ore, […]

How to Improve Cyclone Separation

Good cyclone separation depends upon control of pressure drop, pulp density and apex size. The ‘pressure drop’ may vary but should not change rapidly, and is held at safe levels by keeping an adequate sump level. A falling sump level causes cavitation in the pump and reduction in feed rate; pressure drop in the cyclone […]

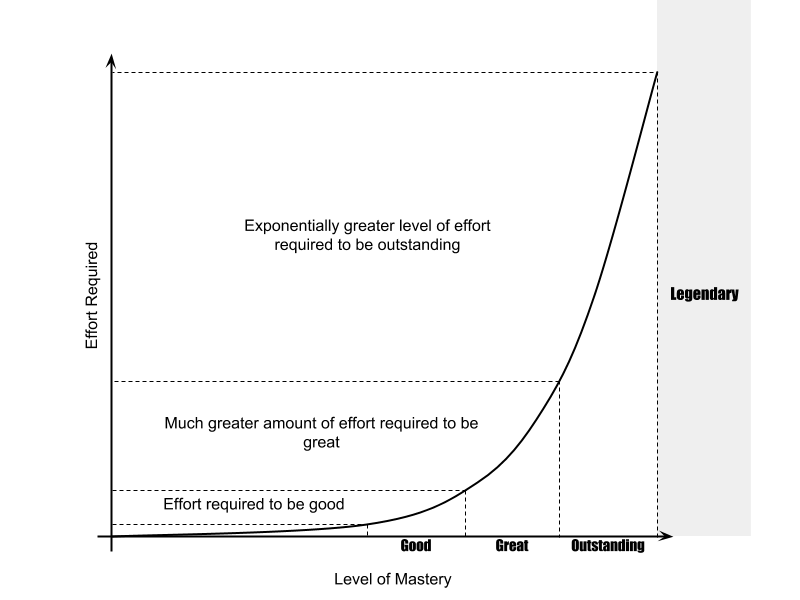

How to Become a Metallurgist

YES! Become a Great METALLURGIST Going from “Being”, to Good, to GREAT! Some say it is a matter of doing certain things. Others say it is a matter of doing things in a certain way. Here a very detailed list of specific skills under the heading “Mineral Processing Basics” that can be further categorised into the following […]