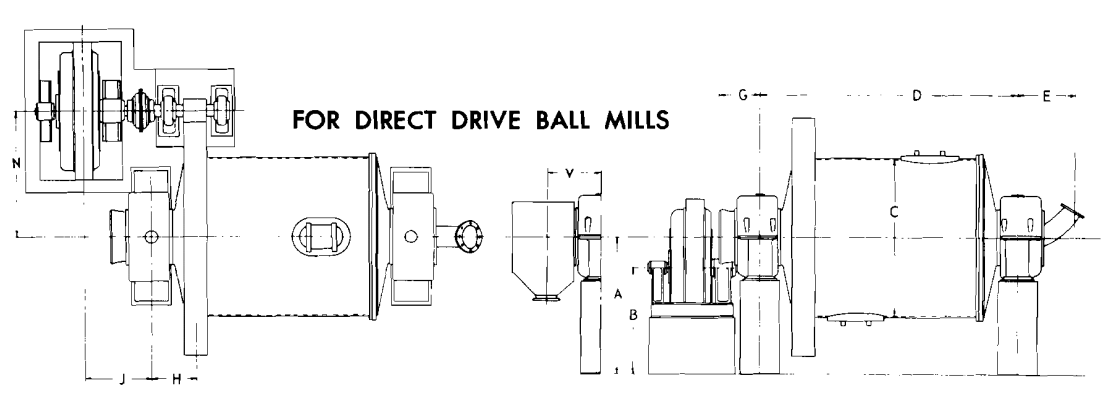

Calculate Ball Mill Grinding Capacity

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially […]

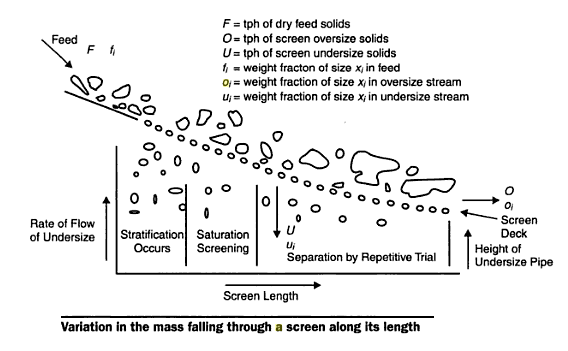

Calculate a Classifier and Screen’s Efficiency

Classifier and screen performance formula: Classification efficiency is generally defined as the weight ratio of classified material in the sized overflow product to the total amount of classifiable material in the classifier feed, expressed as a percentage. For two-product separations, the general form used is: Cytec [/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Calculation of Top Grinding Media Size -Ball Sizing

The majority of grinding balls are forged carbon or alloy steels. Generally, they are spherical, but other shapes have been used. The choice of the top (or recharge) ball size can be made using empirical equations developed by Bond (1958) or Azzaroni (1984) or by using special batch-grinding tests interpreted in the content of population […]

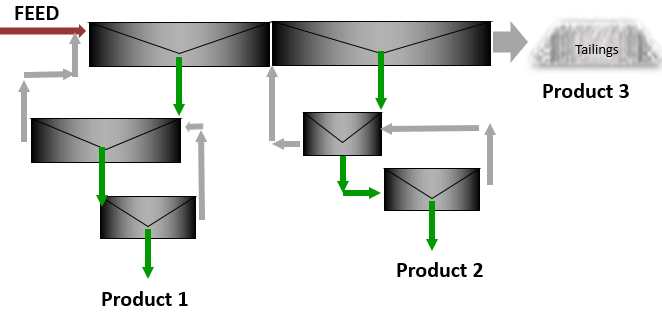

3 Product Recovery Calculation & Formula

In this metallurgical (material/MatBal balance) involving 2 concentrates or 3 products, we have this example: It is decided to take a copper tail (zinc feed) sample in order to provide a check on the results calculated in the previous example. The sample (CT) assayed 0.55% Cu (c5) and 20.9% Zn (z5), respectively. The check weights […]

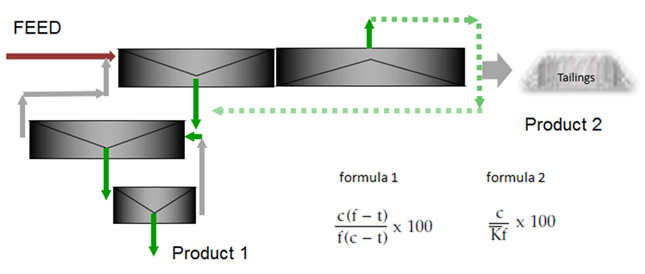

3 Product Recovery Formula: Material Balancing & Metallurgical Accounting

Frequently, a concentrator will mill a complex ore requiring the production of two separate concentrates, each of which is enriched in a different metal or valuable mineral, plus a final tailing acceptably low in both constituents. Formulas have been developed which use the feed tonnage and assays of the two recovered values to obtain the […]

Metallurgical Accounting & Material Balancing: Two Product Formula

Cytec Section 11.6 near page 240 Wills’ Mineral Processing Technology, Seventh Edition: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Hydrocyclone Design and Sizing Parameters

Here is a hydrocyclone sizing calculator with immediate access to all design equations needed for your hydrocyclone design calculation in an online XLS spreadsheet format. Based on first principles of hydrocyclone theory and equations, this quasi design software lets you enter all cyclone design parameters such as cut size, D50, D60 (efficiency calculation), graphs your results. Calculate diameter of […]

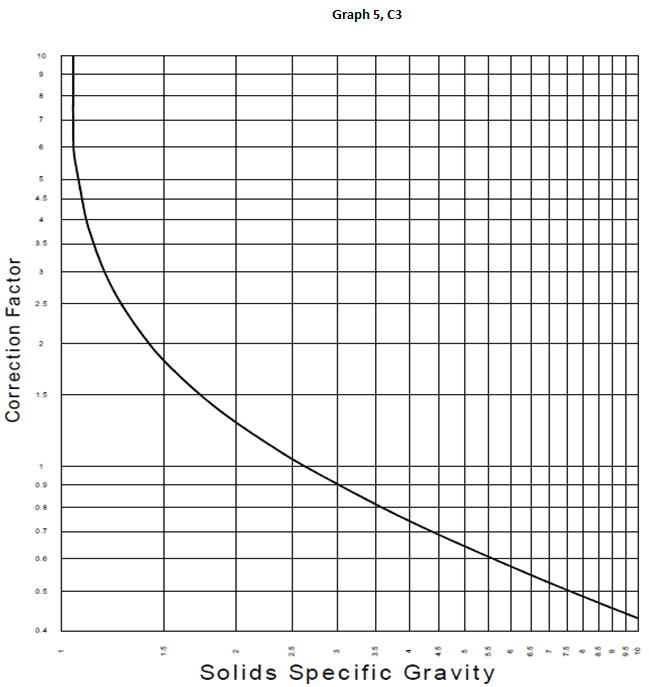

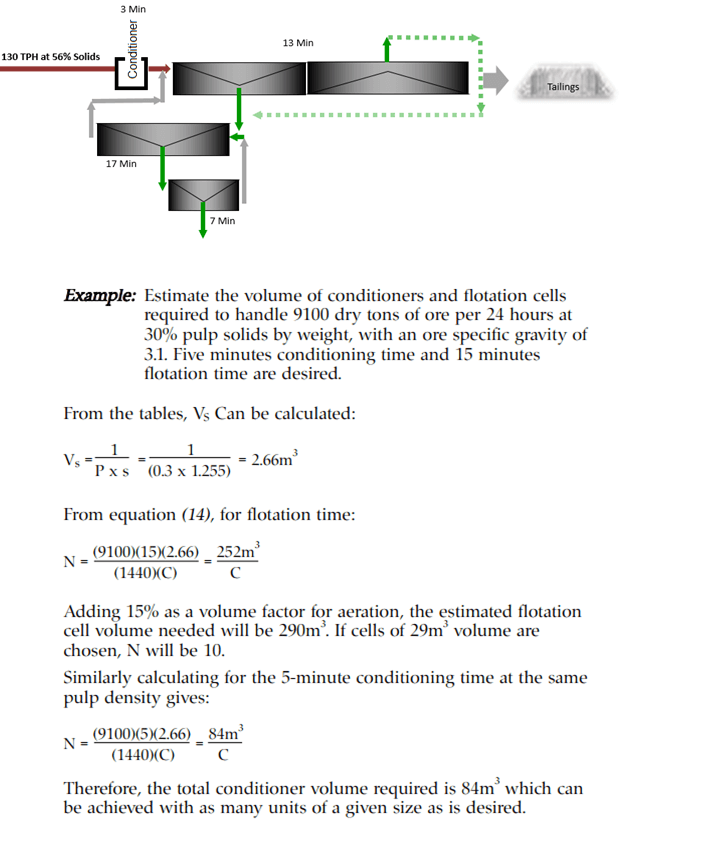

Flotation Cell Capacity vs Retention Time

This online calculator helps you on how to calculate or estimate either what size/volume flotation cell and well as conditioning tank + how many flotation cells your bank needs to accommodate the retention time you need. Design Retention time is usually obtained from laboratory testwork and proper use of Lab-to-Plant flotation scale-up factors. An Example of […]

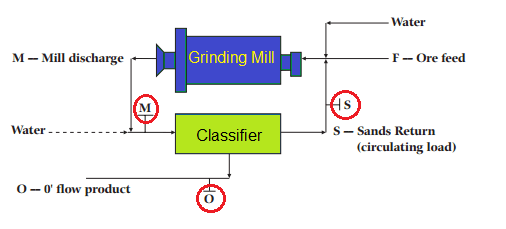

Ball Mill Circulating Load Formula

Calculating a grinding circuit’s circulating loads based on Screen Analysis of its slurries. Compared to %Solids or Density based Circulating load equations, a more precise method of determining grinding circuit tonnages uses the screen size distributions of the pulps instead of the dilution ratios. Pulp samples collected around the ball mill or rod mill and hydrocyclones, screen or […]

Mineral Processing Equations EQ

A Metallurgist or more correctly a Mineral Processing Engineer will often need to use these “common” Formulas & Equations for Process evaluation and calculations: Circulating load based on pulp density *** Circulating load based on screen analysis *** Flotation Cell & Conditioner Capacities *** Two Product Formula *** Three Product (bimetallic) Formula (Part 1) ***needs verify Three Product (bimetallic) Formula (Part […]