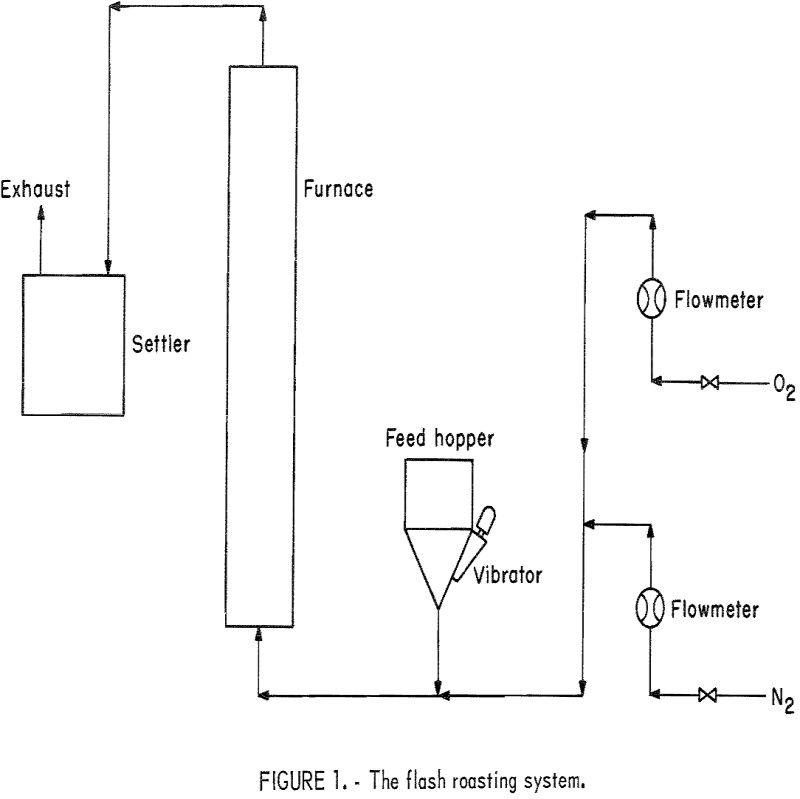

Chalcocite Oxidation Roasting

The Bureau of Mines Twin Cities Metallurgy Research Center is engaged in a study to uncover a cleaner, more direct pyrometallurgical process for winning copper from sulfides. The .initial target is low-sulfur concentrates containing primarily chalcocite (Cu2S). Development work, still in progress, points to a new and, perhaps, improved smelting procedure in which the following […]

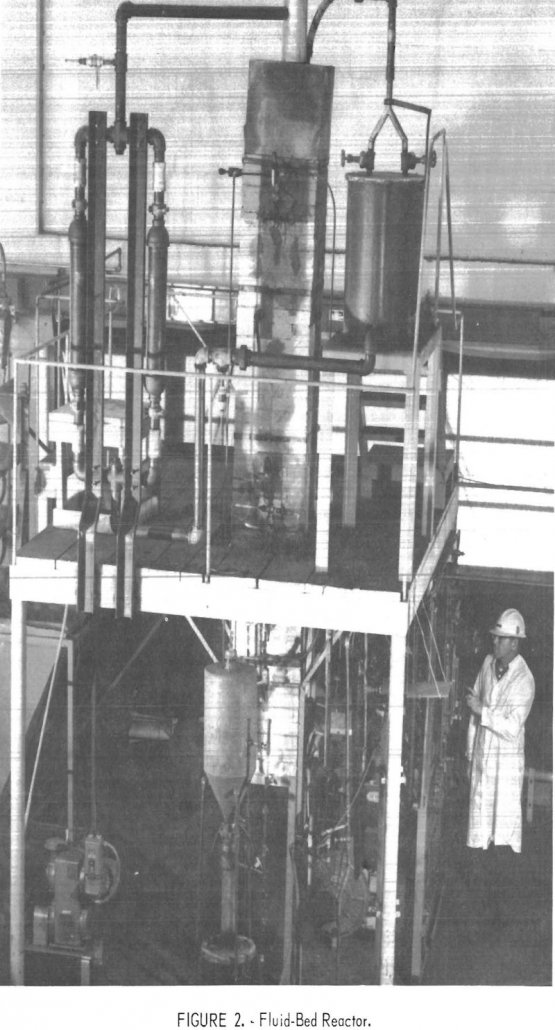

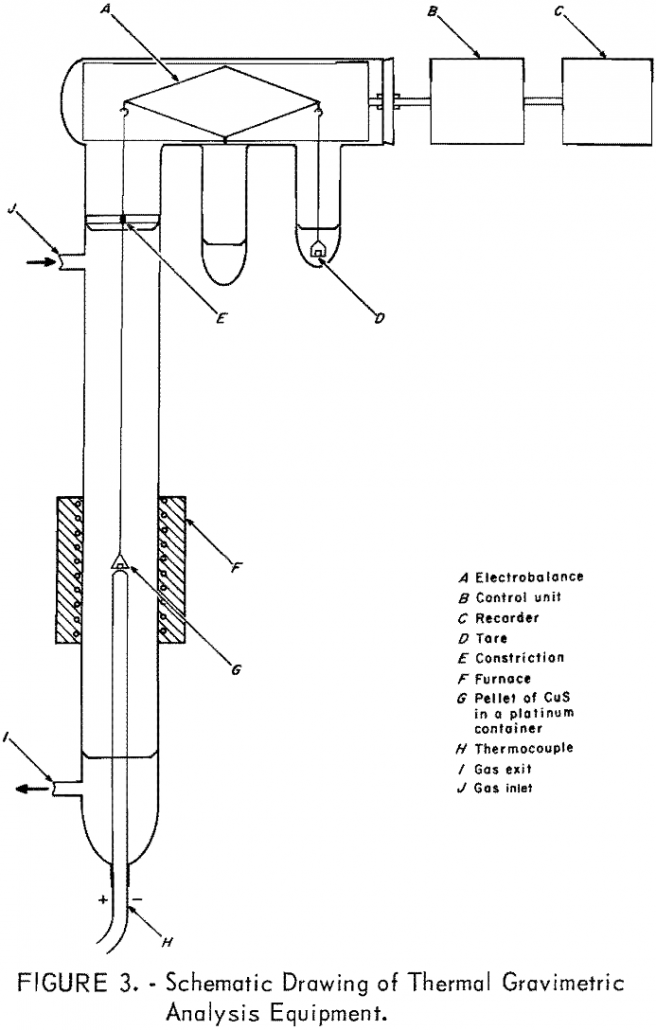

Roasting Copper Sulfides Chemistry

The roasting process is widely used in extracting copper from its sulfide ores. At present the development of a new process for winning copper from pelletized chalcocite concentrate is underway at the Bureau of Mines Twin Cities Metallurgy Research Center. In this process, the dead roasting of sulfide is followed by the reduction of oxide […]

How to Control Sulfur Oxide Emissions in Smelting

The domestic base-metal-producing industry has been challenged with the task of reducing the amount of sulfur oxides and other pollutants emitted by smelters treating sulfide ores and concentrates. This challenge has been imposed by legislation aimed at reducing air pollution. Standards for both ambient air quality and allowable emissions have been proposed and already are […]

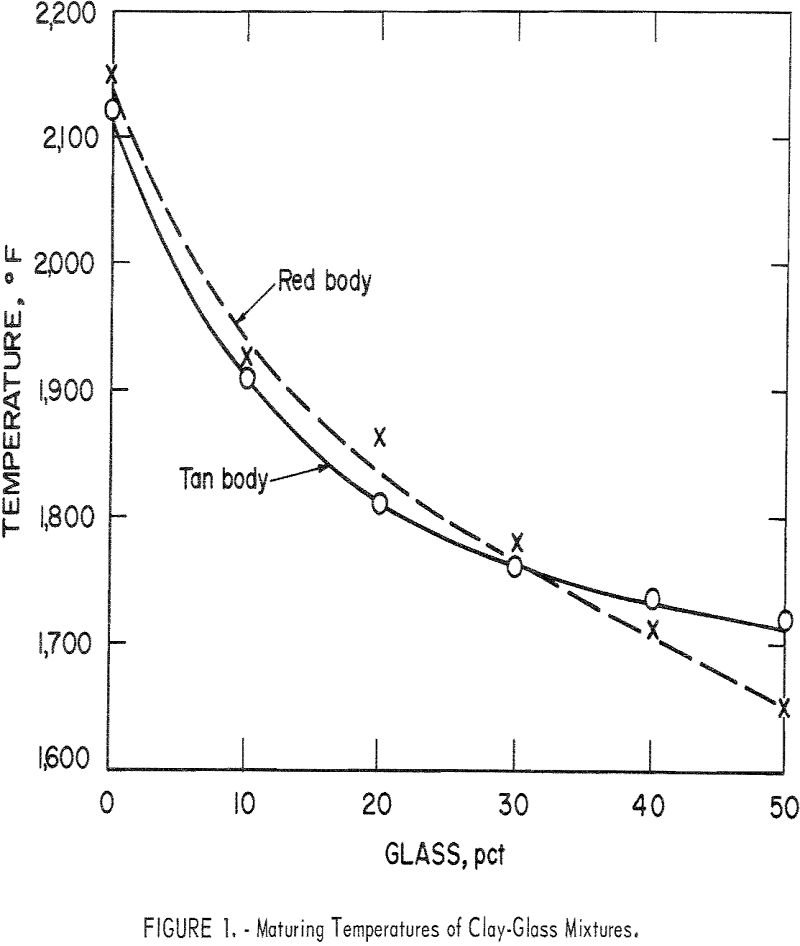

Use Recycled Waste Glass as Flux for Clay Firing

The Bureau of Mines Tuscaloosa Metallurgy Research Laboratory is conducting waste utilization research concerned with the development of building products from metal-free inorganic materials separated from municipal incinerator residues in the Bureau’s continuous residue-processing plant at the Edmonston Laboratory of the College Park Metallurgy Research Center. This is the third in a series of publications […]

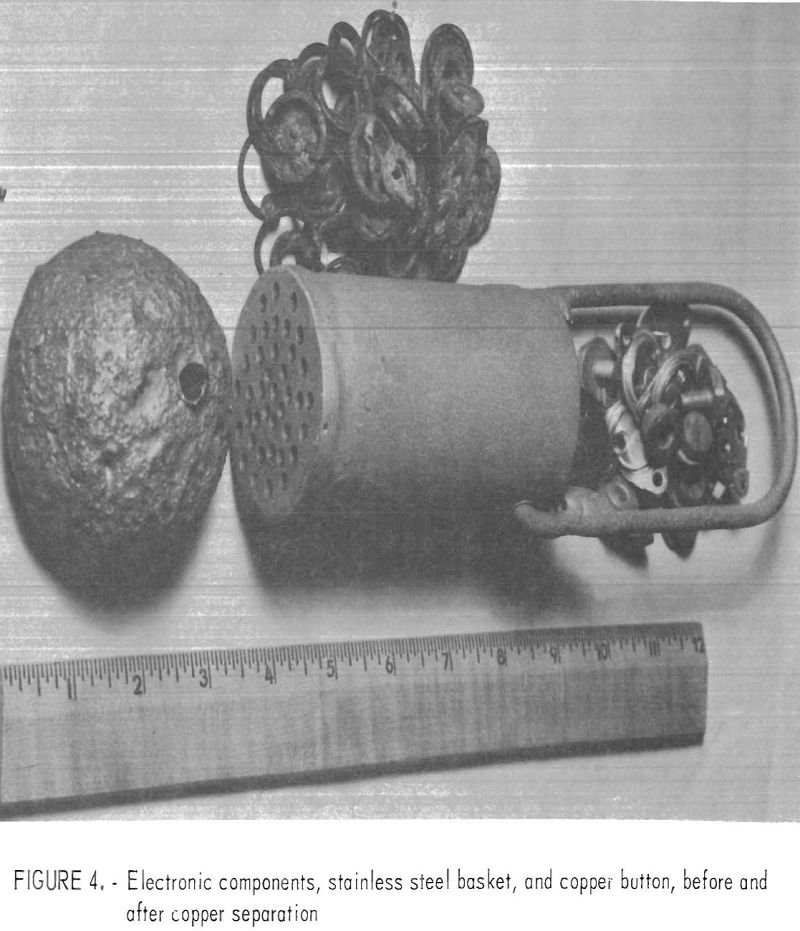

How to Separate Copper from Scrap by Melting

The secondary metals industry has been a major segment of the domestic economy for years. Many secondary commodities (heavy melting steel and lead storage batteries are familiar examples) have become so well established and recycled so promptly that industry commitments for metal would be impossible without them. Although some recovery and refining processes developed for […]

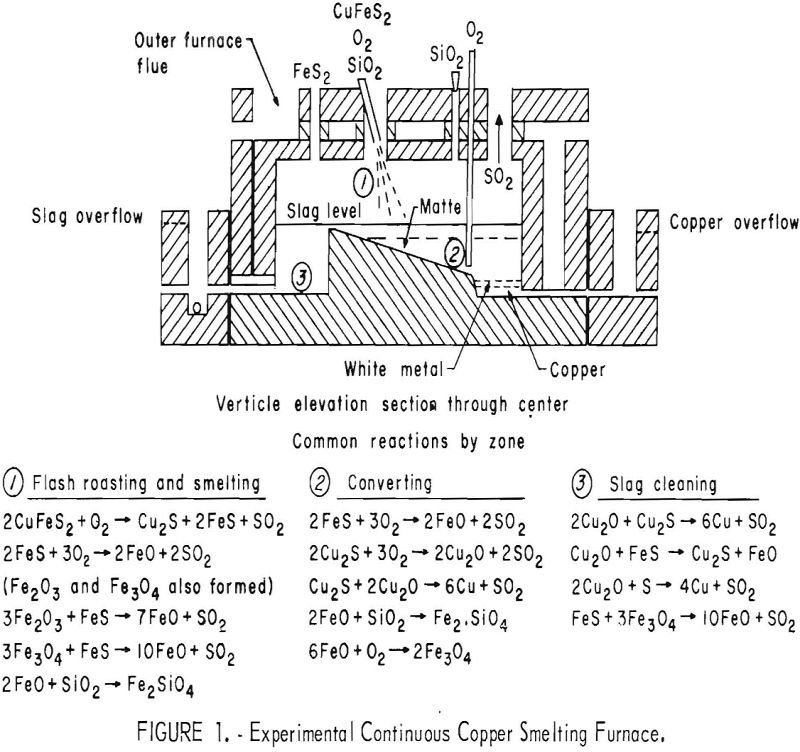

Copper Smelting

Throughout this century the major production of copper (as it relates to Copper Smelting) and most other nonferrous metals has been through pyrometallurgical methods, treating sulfide ores by various batch processes. The predominant copper process is reverberatory furnace smelting of sulfide concentrates to produce matte and slag, followed by treatment of the matte in converters […]

Copper Cement Oxidation

Cement copper production has been increasing steadily because more mine waste from open pit mining is being leached and the copper recovered by cementation on scrap iron. Current estimates indicate that about 13.1 percent of the Nation’s production of primary copper is from this source. Cement copper is usually a crude product containing elemental copper, […]

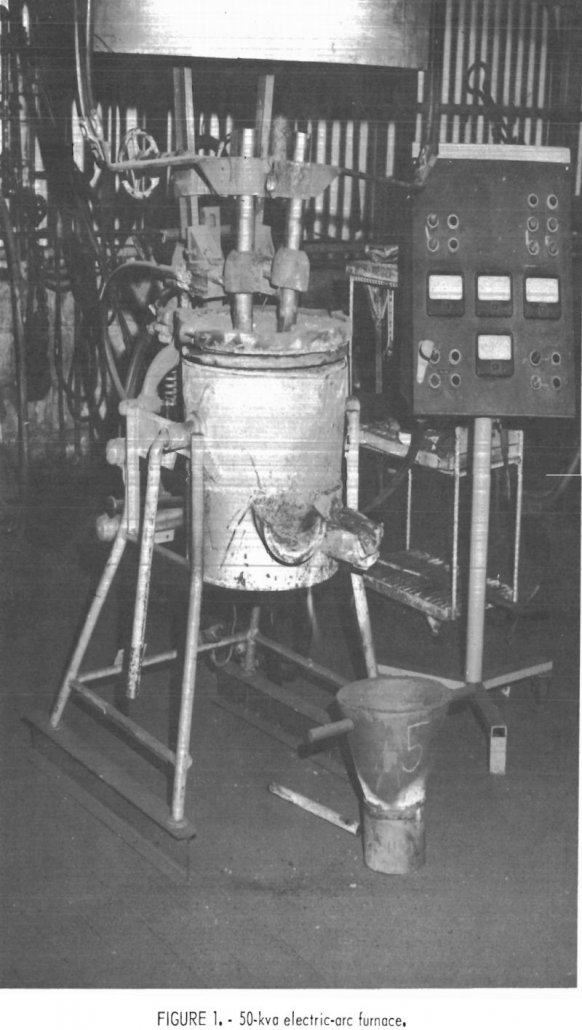

Smelting Nickel Electric Furnace

This Bureau of Mines report results from a study on prereduced nickel concentrate from the FENI project in Yugoslavia; this study was conducted in cooperation with McKee Overseas Corp., Western Knapp Division. The Bureau was particularly interested in establishing the chemical relationships between pre-reduction of low-grade nickel ore and the ferronickel produced by smelting the […]

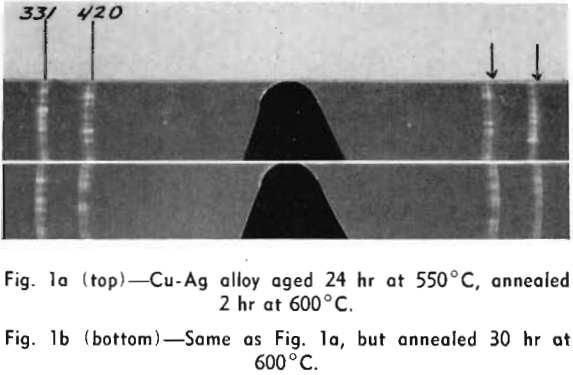

Re-solution of Precipitated Silver in Copper-Silver Alloys

During preliminary tests on the aging of a Cu-plus 5 pct Ag alloy, a specimen which had been overaged 24 hr at 550°C was annealed in a nitrogen-hydrogen atmosphere first for 2 hr and then for an additional 28 hr at 600° C. Conceivably, for Cu-Ag alloys, the matrix-transition-precipitate precipitation sequence is reversible for the […]

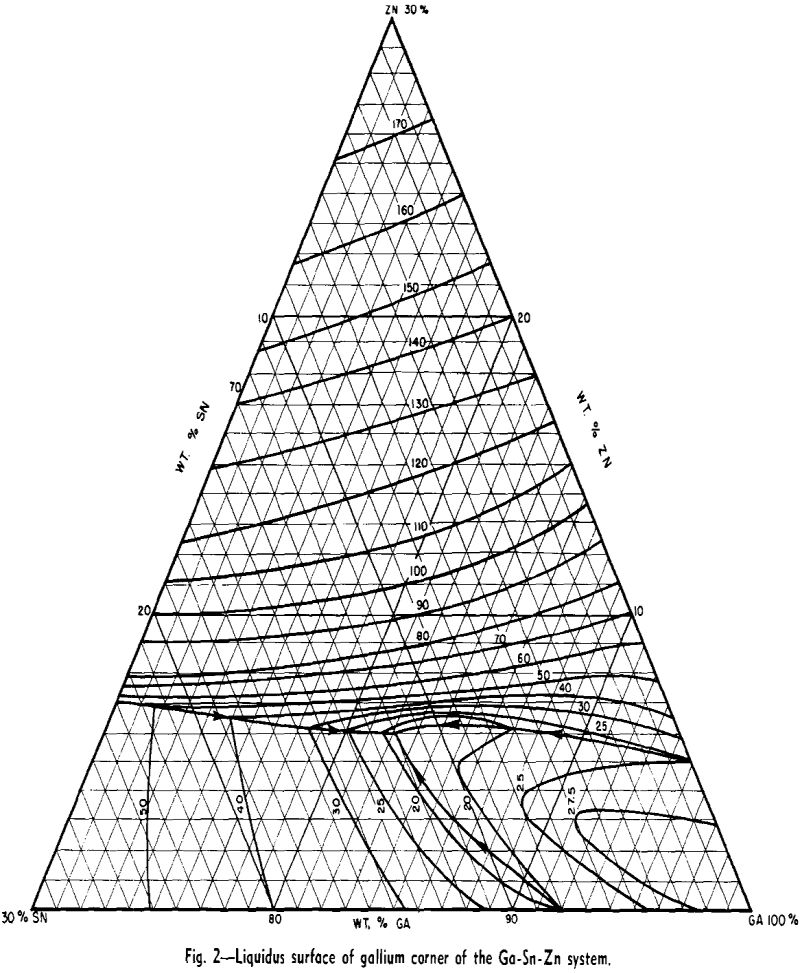

Low Melting Gallium Alloys

In recent years, the interest in liquid metals as heat-transfer media for power plants has been very great. The possibility of the development of nuclear power plants has increased this interest and served as the impetus behind much research on low melting metals and alloys for such purposes. The principal reasons for consideration of liquid […]