Electrolytic Refining: Silver – Gold – Copper

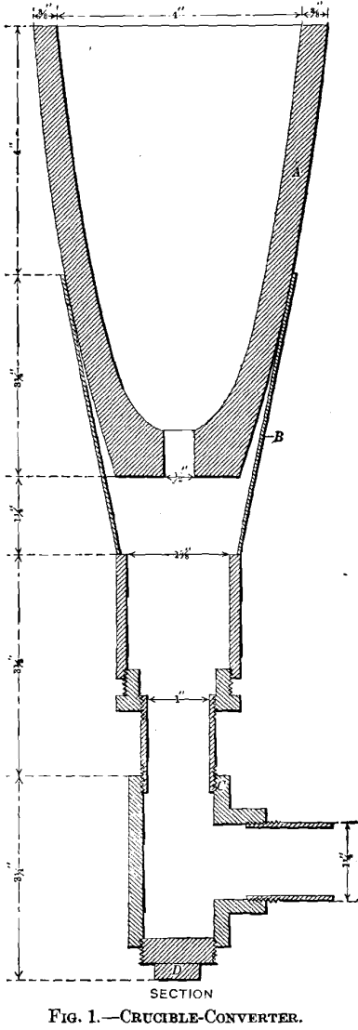

The refinery takes the bullion purchased by the receiving department, and carrying more than 200 parts of precious metals in 1,000, or, in mint parlance, over 200 fine, and separates and refines the various metals contained therein, using electrolytic processes exclusively. Bullion containing silver is treated in cells charged with a nitric electrolyte. These cells […]

Overpoling Electrolytic Copper

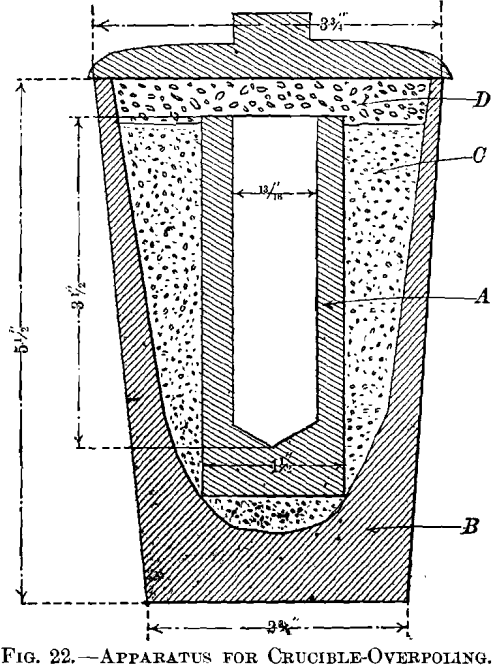

The current meaning of the term, copper overpoled in the reverberatory furnace, is that poling has been carried beyond the tough-pitch stage, with the result that the reduction has been carried too far, causing the copper to become porous and brittle, and thus unfit for industrial purposes. It will be shown that the brittleness of […]

Refining Electrolytic Copper

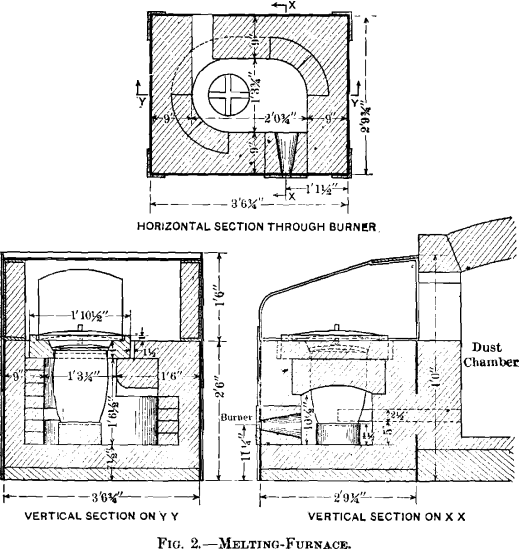

The object of refining copper in the reverberatory furnace is to obtain a metal which will have the highest attainable degree of malleability, ductility and electric conductivity, and present at the same time a level surface when it solidifies in the mold after casting. These desirable physical properties are governed by the character of the […]

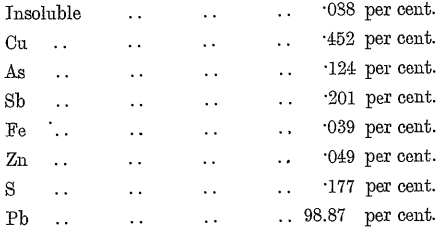

Roasting Galena Concentrate with Lime

Lime Roasting is a term proposed by Ingalls for the operation of forcing air under pressure through a mixture of galena and lime at the kindling-temperature with the object of oxidizing lead and sulphur and of fritting or fusing the charge. If finely-divided galena were treated in this manner without the addition of lime, the […]

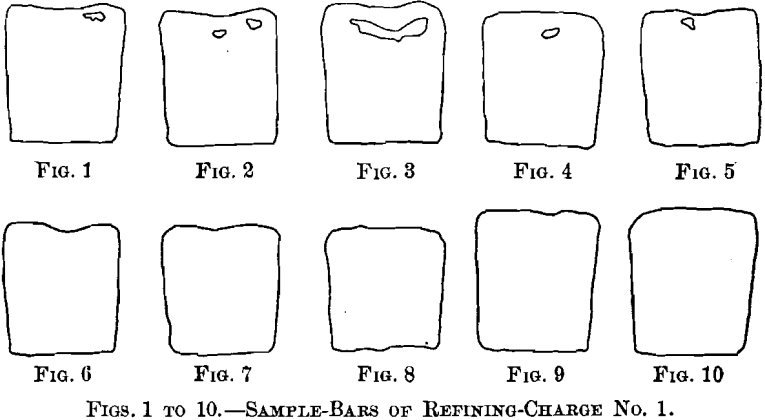

Refining Base Metal Bullion & By-Product Treatment (Pb, Cu, Zn) Bars

Here is a short account of the treatment of the base bullion for the recovery of lead, silver, and gold, and for the treatment of by-products. Appended is a short description of the chief facilities of plant which have been adopted to overcome the main difficulties in the refining of lead. The difficulty of obtaining fair samples […]

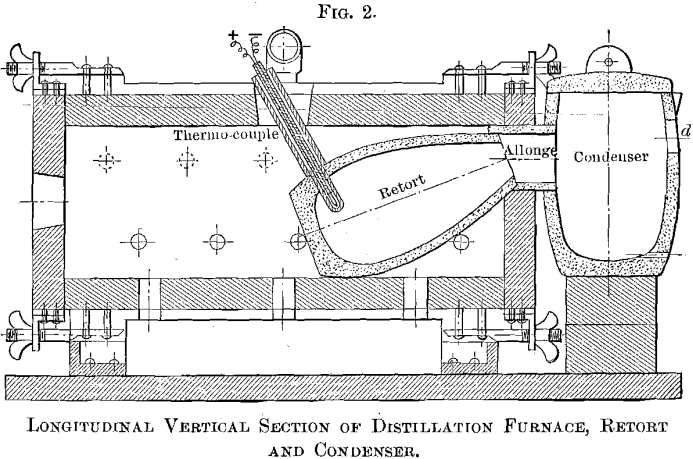

Refining Gold: Remove Zinc by Distillation

It seems desirable to remove zinc more completely than can be done by acid-treatment, and also to obtain it in a form at once available for precipitation again. I feel safe in saying that from 40 to 50 per cent, of the zinc originally used for precipitation could be thus recovered. Philip Argall says, in […]

Wohlwill Process

Smelter Laboratory Equipment List

The work of a chemist at a busy smelting-plant differs radically from the work of a student, who takes all possible care to have his analysis exact within hundredths of a per cent., and has plenty of time to devote to the operation. The works- chemist, having the shortest time in which to make his […]

Factors Affecting Copper Electrical Conductivity

One of the properties of copper, which has done much to give it its present prominent place among the useful metals, is its electrical conductivity,—a property which has now become the chief criterion of the value of the commercial product. In pursuance of that distinctively American principle that, “ the best is none too good,” […]

Refining Zinc Precipitates: Cyanide Leaching of Gold & Silver Extraction

Attempts to discover, for the cyanide process, a better precipitant than zinc have been unsuccessful. Hydrogen sulphide, sulphurous acid, ferrous sulphate, etc., precipitate gold and silver from cyanide solutions either not all or incompletely. Aluminum has been tried, but it costs too much, and cannot be used in solutions containing lime. Charcoal has been used […]