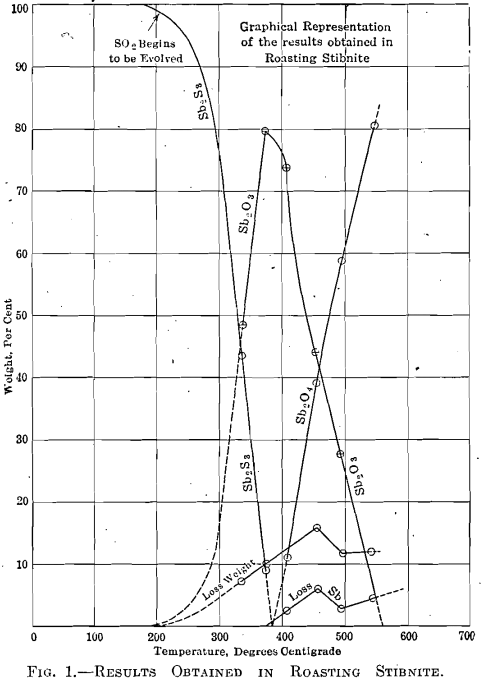

Oxidizing Roast; Stibnite the Antimony Mineral

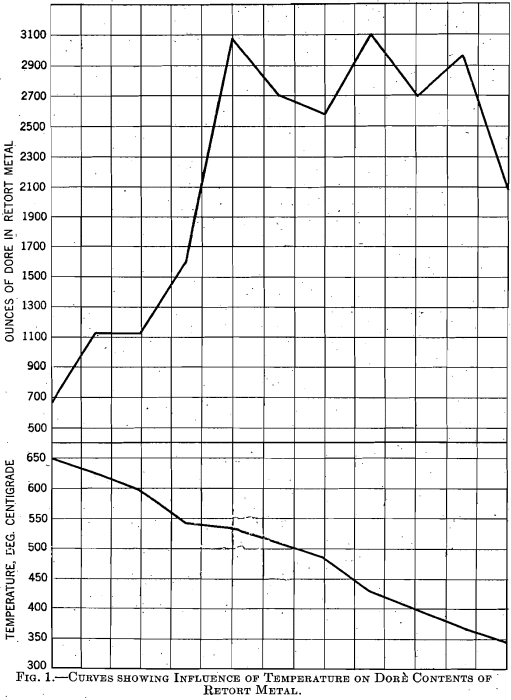

The leading antimony mineral is stibnite. In smelting stibnite ore two processes are available, precipitation and roasting-reduction. The former is suited, only for high-grade ores. As low-grade ores are more common than high-grade, roasting-reduction is of greater importance than precipitation. In the roasting process the aim may be to leave the oxidized antimony in the […]

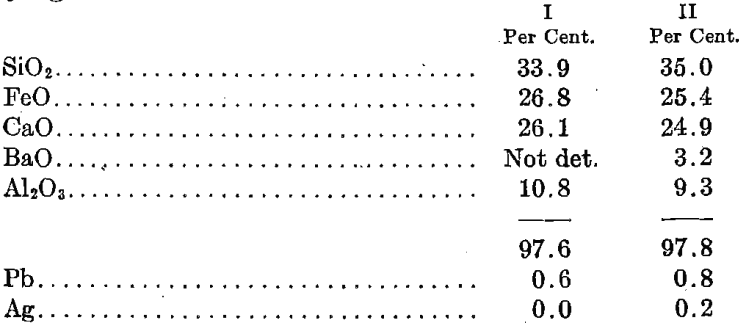

Smelting of Lead Ores using High Lime Slags

Anton Eilers, who was then interested in the lead smelting and refining business near Salt Lake City, Utah, made a somewhat radical departure from the regular practice at that time, which was to use but little lime in the slag, with a high percentage of iron. Lime was not only a cheaper flux than iron, […]

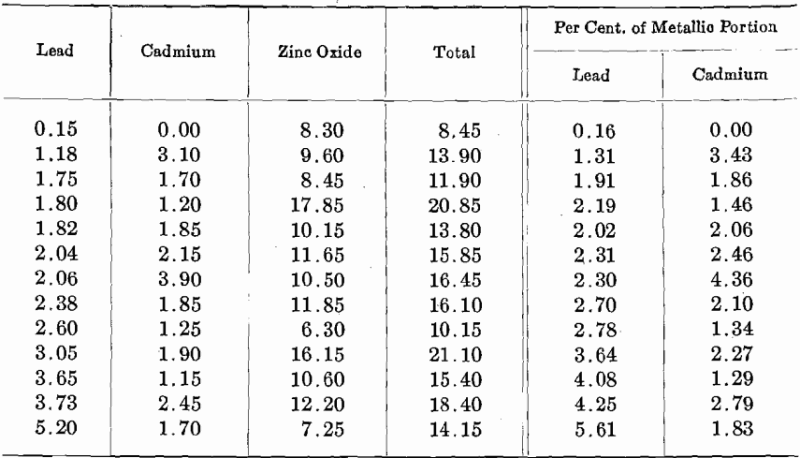

Zinc Dust Precipitation Tests

The use of zinc dust for precipitating the precious metals from cyanide solutions is well established now in many places, and has many advantages over the shavings method of precipitation. Although much work has been done on methods of testing zinc dust, as yet no absolutely positive test has been devised to determine the value […]

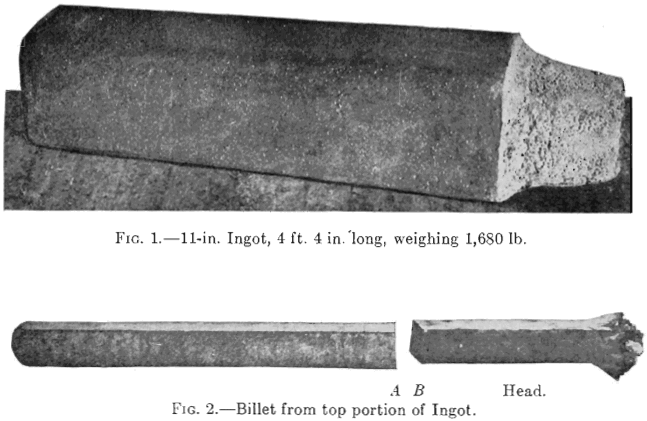

Sound Steel Ingots

Last year this Institute was good enough to accept some remarks by the writer regarding sound steel, entitled Plant for Hadfield Method of Producing Sound Steel Ingots, being a continuation of a research in which for some time the writer has been engaged, and full particulars of which were submitted in papers entitled A New […]

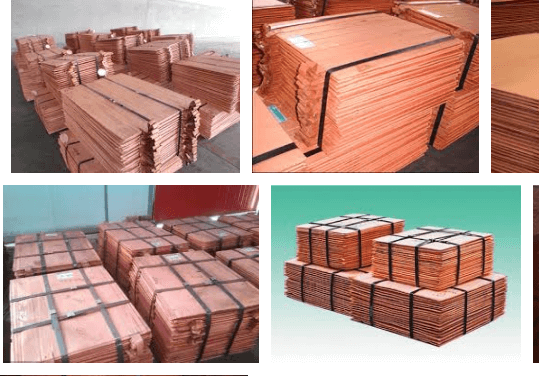

Melting Copper Cathode in Electric Furnace

The electric furnace has always been found to be especially adapted to melting, refining, and finishing processes throughout its gradual acceptance by metallurgists as a practical apparatus for conducting metallurgical operations. In the steel industry, the electric furnace is firmly established in the manufacture of steel of the highest grade, equal to crucible steel. For […]

URANIUM, RADIUM & VANADIUM Ore Processing #2

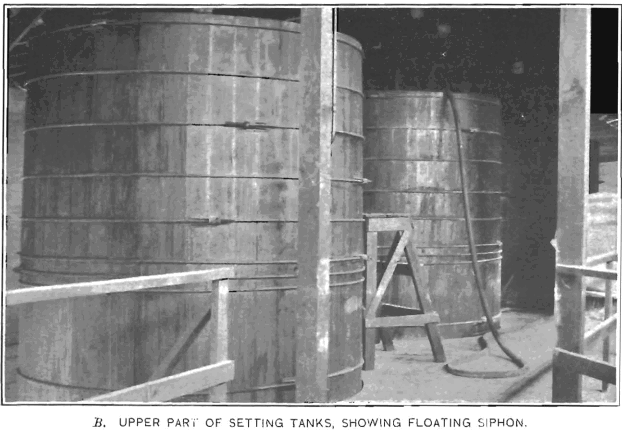

The method of treating carnotite, a uranium, ore used by the Bureau of Mines is outlined in this chapter. Leaching, Filtering, and Washing Ore The ore is ground to 20 mesh and is leached with strong hot nitric acid in acid-proof earthenware pots. The amount of acid used is 121 pounds of 100 per cent […]

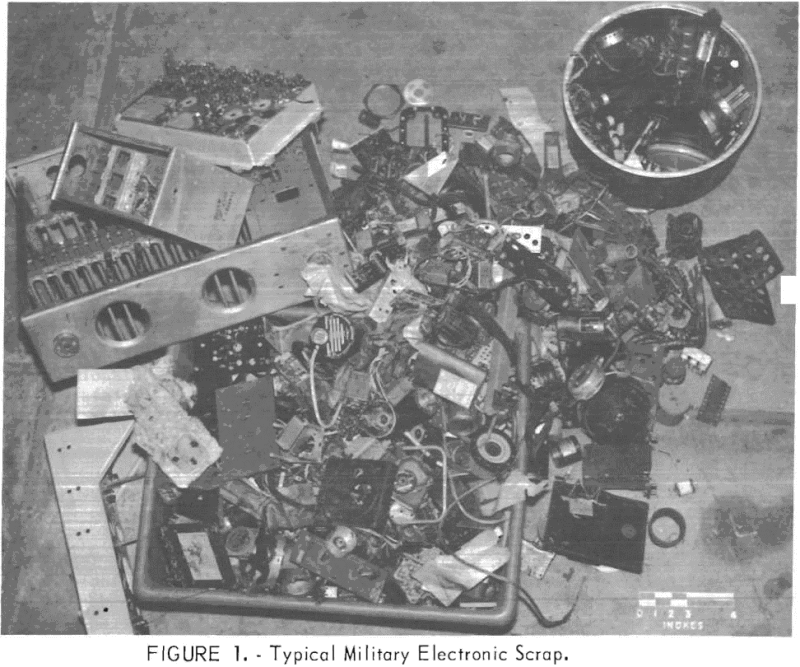

Electronic Scrap Precious Metals Recovery: Gold, Silver, Platinum

The Bureau of Mines investigations described in this report were undertaken to devise a process to economically recover precious metals and copper from low-grade, complex electronic scrap generated in large quantities by military and civilian electronic operations. Leaching with various media is applicable to certain selected items of electronic scrap but cannot be practically applied […]

RADIUM, URANIUM & VANADIUM Extraction & Recovery #1

Until recently little had been published on methods of treating any of the uranium ores for the extraction of radium, although a number of patents have been issued both in this country and abroad. Therefore persons interested in methods of extracting radium have had little to guide them, as details of the methods in use have […]

Effect of Zn3Ag2 on Desilverization of Lead

Refiners of lead by the Parkes process have always been solicitous of recovering the zinc used in the desilverization, and justly so, as the loss in zinc constitutes one of the heavy costs in this method of refining. Part of this loss is due to the absorption of zinc by lead, and in the present […]

Copper Precipitation Methods

In a leaching process, having obtained the copper in solution, the choice of the precipitation method is influenced by the following factors: Availability of precipitant. Adaptability to the leaching process. Final product desired. Regeneration of leaching solutions. Fouling of solutions. There are three general classes of copper precipitation methods: 1. The copper precipitation by use […]