Fine Gold Recovery & Refining

How to Remove Copper from Fine Gold Prevention of copper entering the final bullion has been the principal objective of all experimental work performed on zinc slimes in the goldroom. Above all other metals encountered during treatment, it is the most difficult to separate from gold and silver. Broadly, two methods are possible for elimination […]

Precious Metal Refinery Procedures

Recovery of Metals from Mattes and Slags Long ago, mattes and slags, which were the end products of the matte smelting process described in Part I, were sent to Port Kembla for final recovery of their metal content. Approximately 15 tons of slag and eight tons of matte used to be shipped yearly. Shortage of […]

Gold Refinery Procedures

Before processing by the gold refinery, gold can be extracted from ore by the following series of operations: Coarse crushing; Fine grinding; Straking for free gold; Flotation; Concentrate roasting; Straking for free, gold; Cyanidation of concentrates; Precipitation of gold from cyanide solution. The last operation is performed in a Merrill-Crowe radial leaf type precipitator, to […]

Type of Melting Furnace

The following may be said to be essential characteristics of a furnace for determining the melting point of refractories: It should be capable of easily reaching a temperature of 1800° C., since most refractories melt below 1800° C.; for those materials melting over 1800° C., special procedure and technique are usually required. The atmosphere in […]

Melting Point of Refractory Materials

The object of this paper is to discuss the factors and conditions that affect the observed values of the melting points of refractory materials and to describe practical methods for the determination of these points. While it appeared to be necessary to discuss some of the general properties of silicates and refractories, these subjects have […]

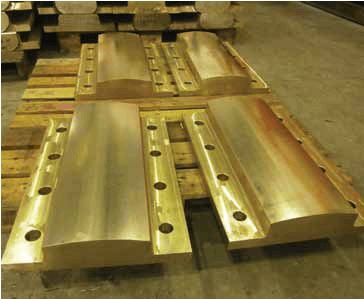

Manganese Bronze

Developments in engineering during the past decade, particularly as applied to marine construction, mining machinery and other purposes in which corrosion offers a serious problem, have created a large demand for a non-ferrous metal highly resistant to corrosion and at the same time useful in general construction work as a substitute for steel without materially […]

Zinc Dust in Precipitant in Cyanidiation

In the cyanide process, gold and silver are dissolved from crushed ore as double alkali-metal cyanides, from which they may be precipitated by such positive metals as sodium (amalgam), aluminum, or zinc, or by electrolysis. Two extreme conditions may be noted. Some works, especially slime plants practising decantation, use a relatively large volume of solution—possibly […]

Desilverization of Lead – Pattinson Process

When Hugh Lee Pattinson discovered, in 1829, that the crystals formed during the slow cooling of molten lead were poorer, and the remaining liquid richer in silver, than the original lead, an important step was made in the metallurgy of this metal. Being the first process applicable to the desilverization of low-grade lead bullion, it […]

Melting Copper Cathodes

The melting of cathode copper, usually containing 99.98+ per cent. Cu, would appear to be a simple matter. Owing to the well known affinity of copper for sulphur, however, so much sulphur is absorbed by the copper during the operation that a long and expensive refining process is required to remove it, and the final […]

How to Make Cement From Blast-Furnace Slag

The successful establishment of iron blast-furnace plants at Newcastle and Lithgow naturally invites attention to the economic utilization of the various products and by-products arising out of the industry. The general similarity in composition between Portland cement and iron blast-furnace slag very early attracted attention both in the cement and iron-smelting industries. Probably the first […]