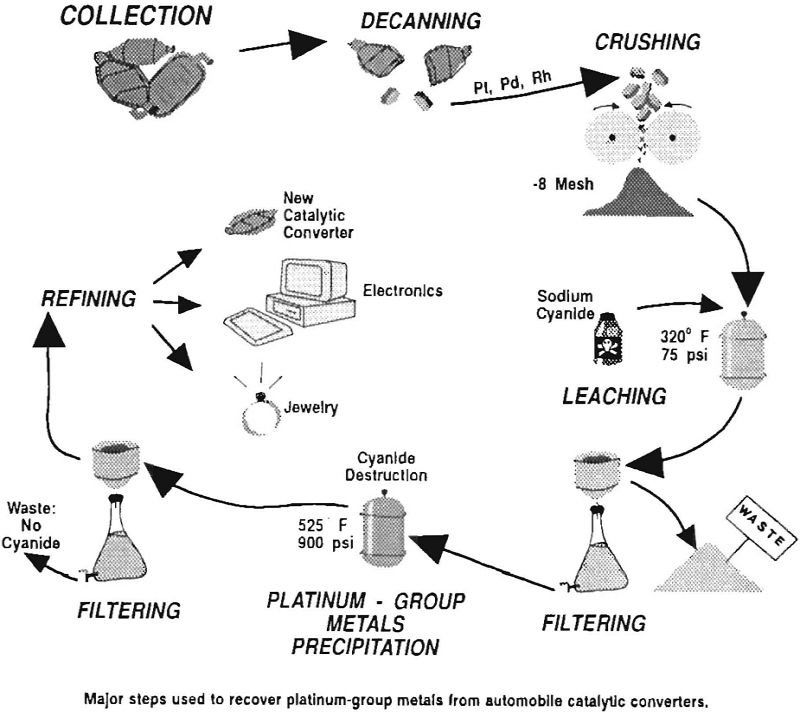

Recovering Platinum-Group Metals in Catalytic Converters

Develop new technology to encourage domestic processing of automobile catalytic converters for recovering platinum-group metals. Background Automobile catalytic converters are used to convert pollutants in automobile exhaust into water vapor, carbon dioxide, and nitrogen. About 1 million troy ounces of platinum-group metals arc used each year in the United States to manufacture catalytic converter. It […]

Recover Neodymium from Permanent Scrap Magnet

Develop hydrometallurgical or pyrometallurgical recycling methods to recover valuable rare-earth compounds from various forms of NdFeB magnet scrap. The U.S. Bureau of Mines (USBM) has developed technology to treat and recycle a variety of wastes containing valuable and strategic metals. As part of this effort, the USBM developed a process to separate neodymium and other […]

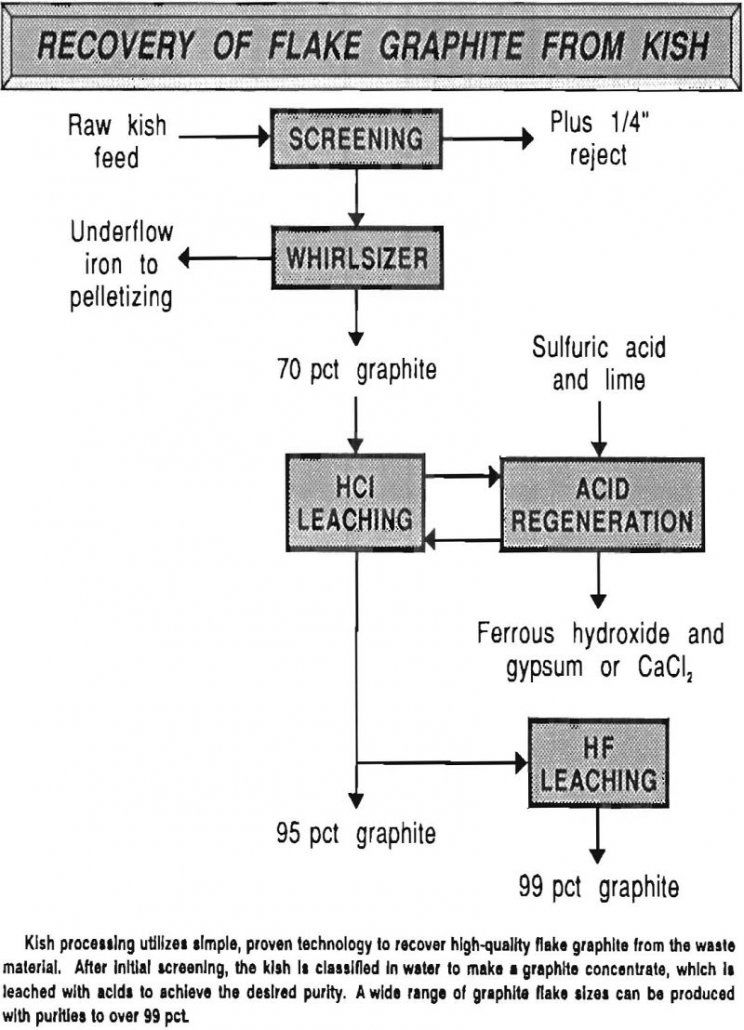

How to Make Graphite Flakes from Steel Waste

Develop a technology for producing high-quality flake graphite from the steelmaking waste known as kish. Approach: Treat the waste kish as an ore and apply mineral processing techniques of physical beneficiation and chemical purification to produce a range of graphite products competitive with the natural mineral. Graphite is a naturally occurring form of carbon with a […]

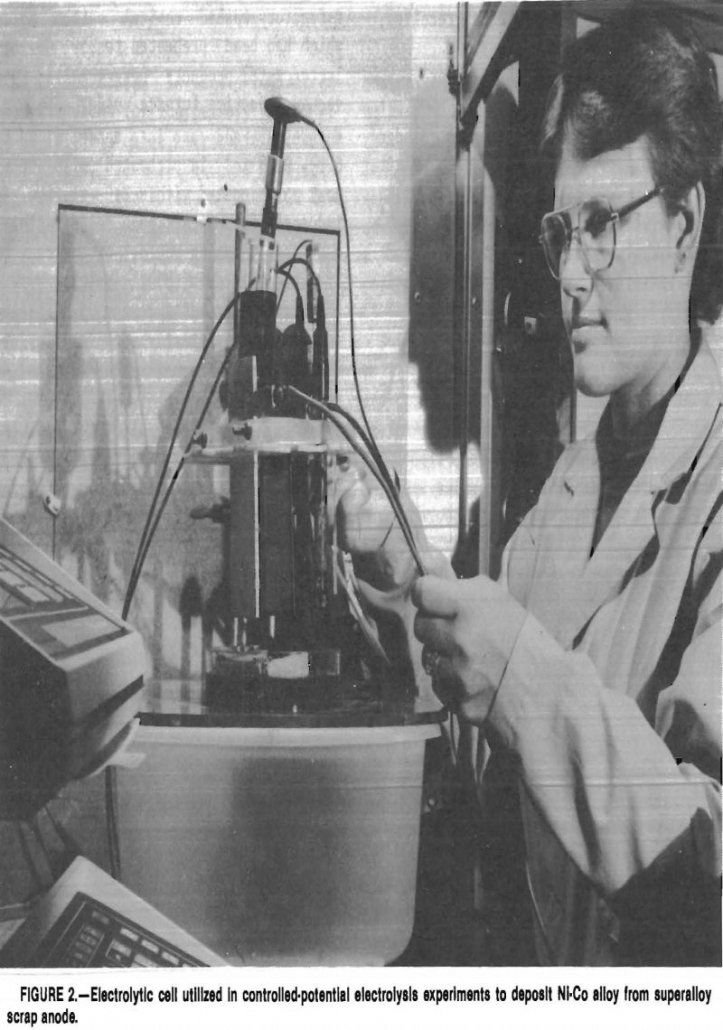

How to Recover Nickel Cobalt Scrap

We are developing improved technology to increase the recycling of mixed contaminated Cr-Co-Ni-bearing scrap and waste materials. According to a study of critical metals availability approximately 125 million lb/yr of mixed contaminated superalloy and associated heat- and corrosion-resistant high-alloy scrap is downgraded or exported. Even though Co usage has dropped in recent years, appreciable amounts […]

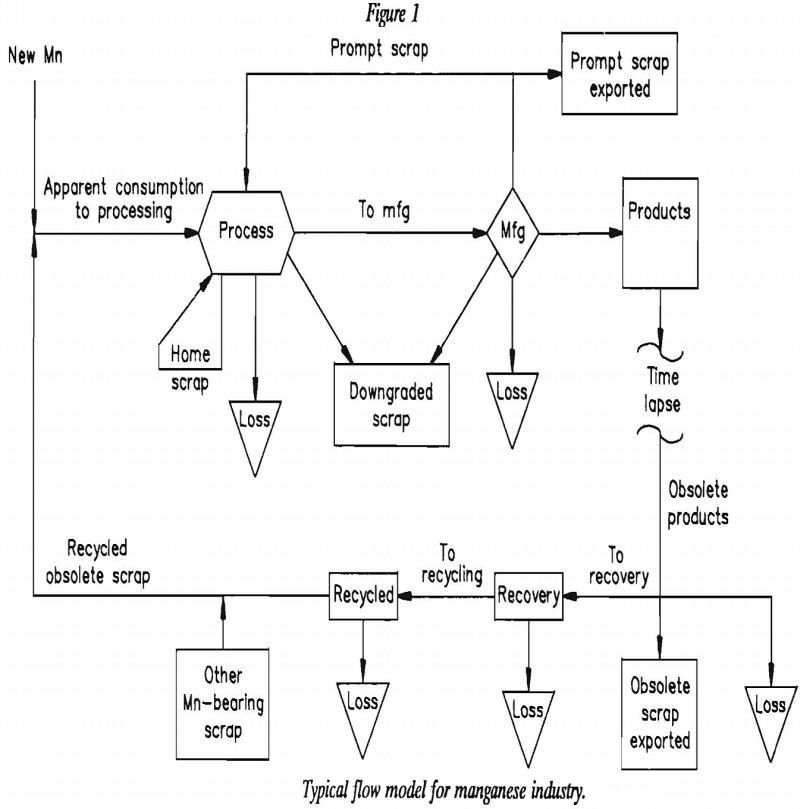

Manganese Recycling

Manganese Recycling is essential to iron and steel production in the United States. Demand in metallurgical applications accounts for most of the manganese consumed in the United States, with ironmaking and steelmaking alone consuming 82 pct. The importance of manganese is related to the functions it performs. Manganese controls oxygen and sulfur impurities in steel, […]

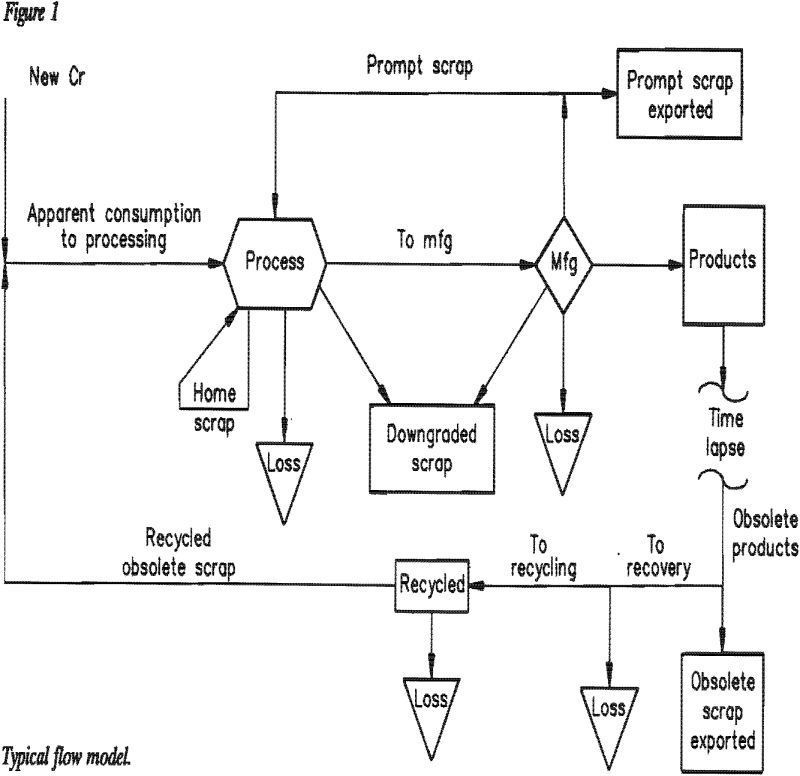

Chromium Recycling

Chromium is an indispensable element in a variety of strategic and critical applications. It is used to produce steels, superalloys, refractory brick, and a variety of chemicals. There is no substitute for chromite ore in the production of chromium ferroalloys, chromium chemicals, or chromium refractories. There is no substitute for chromium in stainless and heat-resistant […]

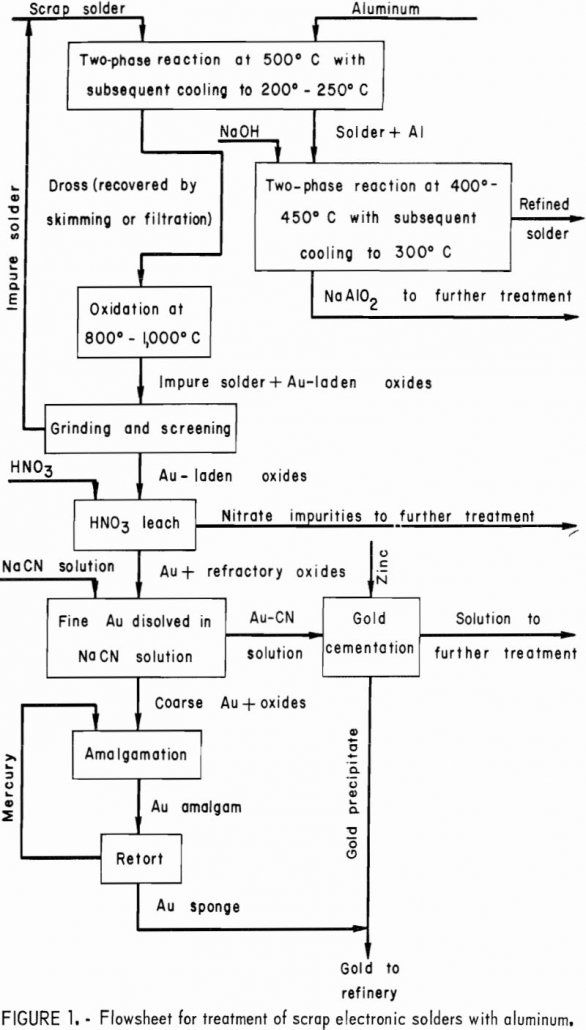

Recover Scrap Electronic Gold

For several years, the Bureau of Mines has been actively involved in developing techniques for recovering and recycling metals and alloys from industrial scrap, including waste materials generated by the electronics industry. Among the latter materials is tin-lead solder that has become contaminated with gold and other impurities to a point where it no longer […]

Gold Analyzer XRF Gold Tester

The 911MPEXRFE is the most affordable unit in the line-up of handheld X-ray fluorescence (XRF) analyzers designed for fast, accurate results. Easy-to-use and reliable, this Gold Analyzer XRF Gold Tester incorporates the features and rugged design of the XRF family. With fast Alloy ID for screening, sorting and metals analysis, the Element provides fast ROI for Scrap, PMI, QA/QC and Jewelry/Precious […]

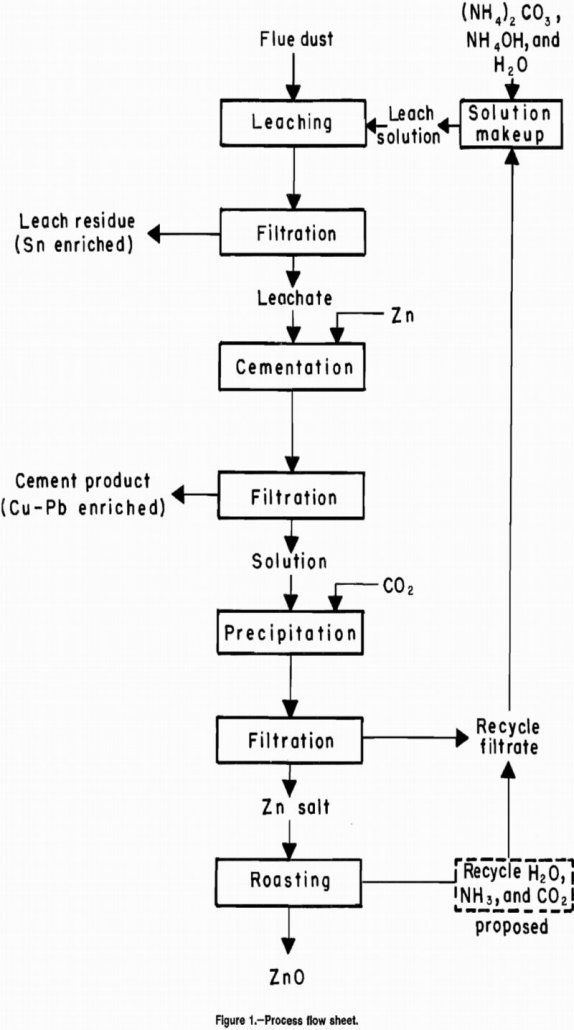

Secondary Copper Converter Dust Metal Recovery using Ammoniacal Carbonate Leaching

Effective recycling or disposal of flue dusts is a continuing problem, particularly for secondary smelters treating low-grade Cu scrap. The Bureau of Mines investigated a variety of flue dust treatment approaches and demonstrated the technical feasibility of a bench-scale alkaline method that includes leaching, cementation, precipitation, and roasting. Flue dust was leached at room temperature […]

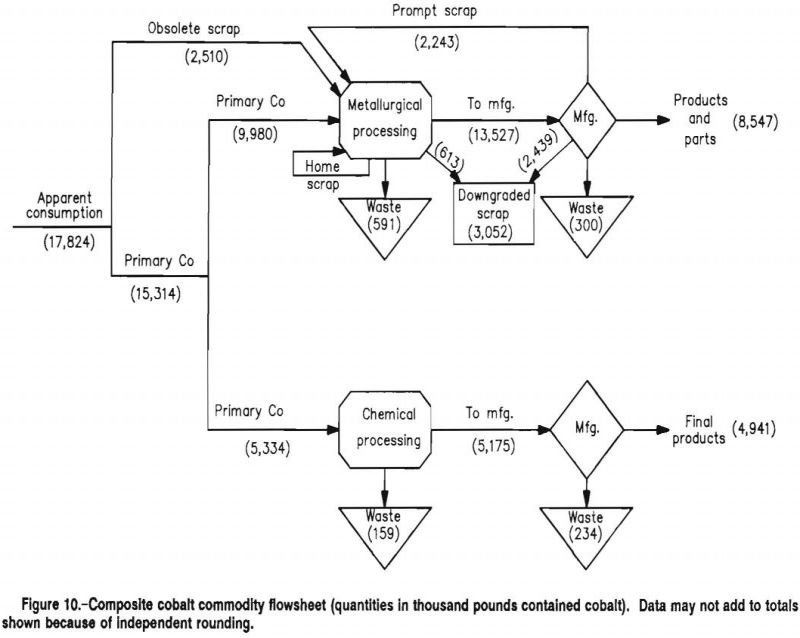

Cobalt Recycling

World resources of cobalt appear ample for the foreseeable future; however, political and economic events have caused concern over the availability and reliability of an uninterrupted supply. Because of this concern, the U.S. Congress requested that the U.S. Bureau of Mines initiate a study of the flow of cobalt in the economy that would delineate […]