Copper Lead Concentrate Separation

The ways to obtain successful Separation of Copper and Lead into individual Concentrates, several process approaches can be examined; bulk copper-lead flotation with a reverse flotation stage depressing copper, the same bulk flotation with a reverse flotation to depress lead and a sequential copper-lead-zinc flotation circuit as well as a simple cleaning of the bulk Cu/Pb concentrate by Pb […]

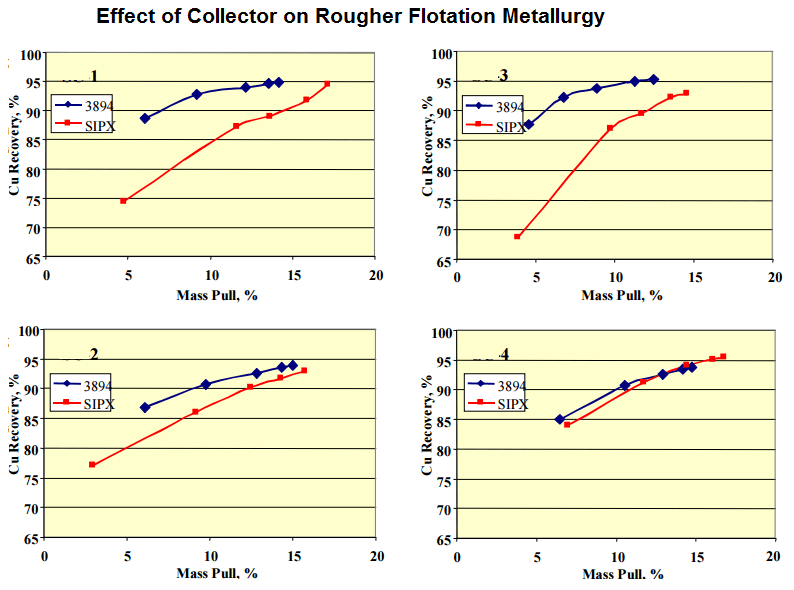

Effect of Collector on Copper Flotation Metallurgy

A pretty clean and relatively easy to treat ore was tested suggesting a collector optimization strategy would probably yield only relatively minor incremental metallurgical improvements. Therefore, collector suite fine-tuning was deemed largely better left for future optimization, possibly when the plant is in operation. In earlier studies Sumitomo had adopted the use of thionocarbamate Cytec […]

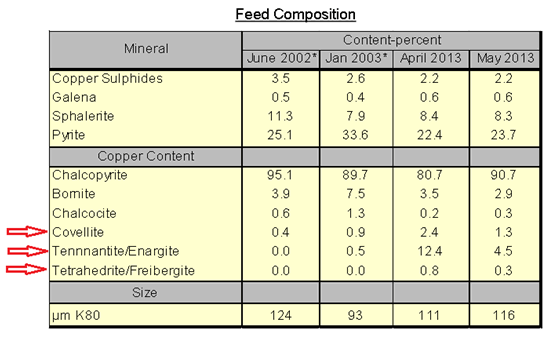

Arsenic in Copper Concentrate

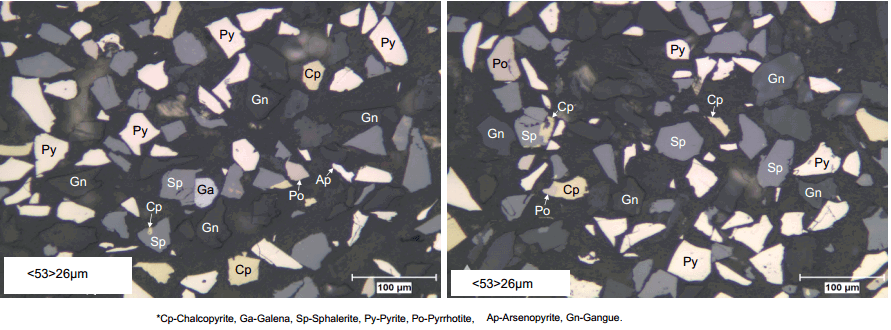

In a certain case study of “high” Arsenic in Copper Concentrate (almost 0.5% As) produced by flotation, and where the Cu Conc is mostly chalcopyrite and therefore the main form of copper; the content of secondary copper minerals was variable. Tennantite/Enargite/Freibergite, a copper-arsenic sulphide mineral, as well as covellite, was present in significantly higher amounts today. […]

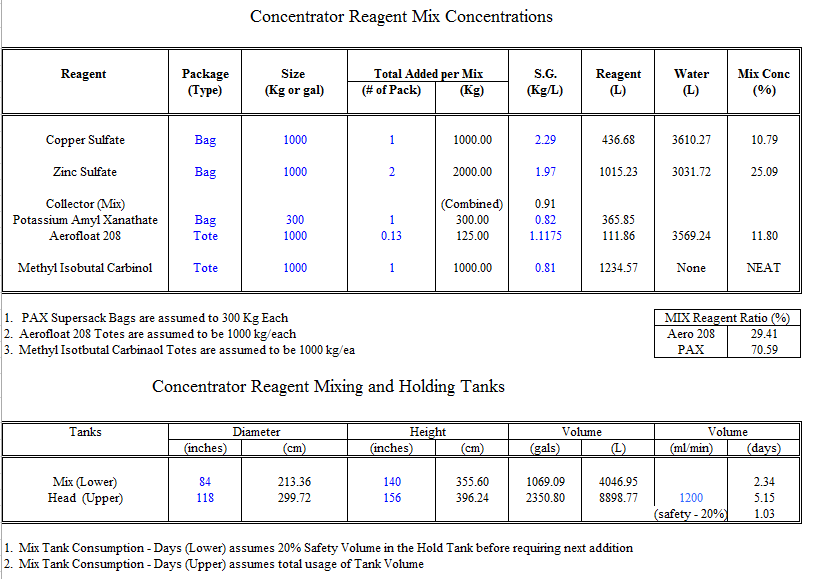

Flotation Reagent Mix Concentration Strength

Just an example of strength at which flotation reagents can be mixed at in a Concentrator:

Titration of Cyanide Solutions Containing Dissolved Copper

When silver nitrate is added to sodium cuprocyanide of the composition Na2Cu(CN)3, an appreciable amount must be added before a precipitate comes down. The reactions are believed to be as follows: 2 Na2Cu(CN)3 + AgNO2 = 2 NaCu(CN)2 + NaAg(CN)2 + NaNO3 On further addition of silver nitrate, a precipitate of CuCN begins to come […]

Lime Slaking Equipment

A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation circuits. A pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit. Other lime […]

SO2 Manufacturing Process – Sulfur Burning Plant

The SO2 Manufacturing Process is “simple”, all you need is a sulfur burning plant. The flowsheet represent what you need for a sulfur burning system to produce SO2. The manufacturing of 1 metric tonne per day of SO2 requires a sulfur-burning SO2 plant capable of smoking-up around 46 lb/hr (21 kg/hr) of sulfur to produce 92 lb/hr (42 […]

SO2 Plant Block Diagram

PART INCLUDE Sulfur Melter Dual Submerged Sulfur Metering Pumps Sulfur Mass Flow Meter (steam jacketed) Sulfur Supply Piping (steam jacketed) Sulfur Burner Atomizing Air System Steam and Condensate Piping for Melter and Sulfur Piping Main Process Air Compressor Ignition Air Heater Sulfur Burner Vessel Refractory Liner for Sulfur Burner Hot SO2 Gas Duct Refractory […]

Stage Addition of Flotation Reagents

In Laboratory, the quality of the concentrate floated in the 1st minute of rougher improves if reagent/collector is stage-added. Stage-adding collector involves adding ½ the total dosage to the 1st cell + ¼ to the 2nd and ¼ to the 3rd or 4th cell. It can be expected a similar metallurgical behavior could be […]

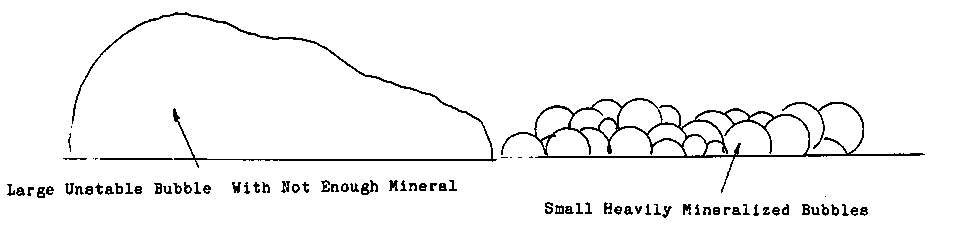

Flotation Frother Dosage

Now for the FROTHER, if there is TOO LITTLE frother the bubbles will become small and the speed of the overflow will be slow. If this condition continues the speed will become slower and slower as the collector overloads the bubble. Soon the froth won’t move at all. The colour will remain correct. On the […]