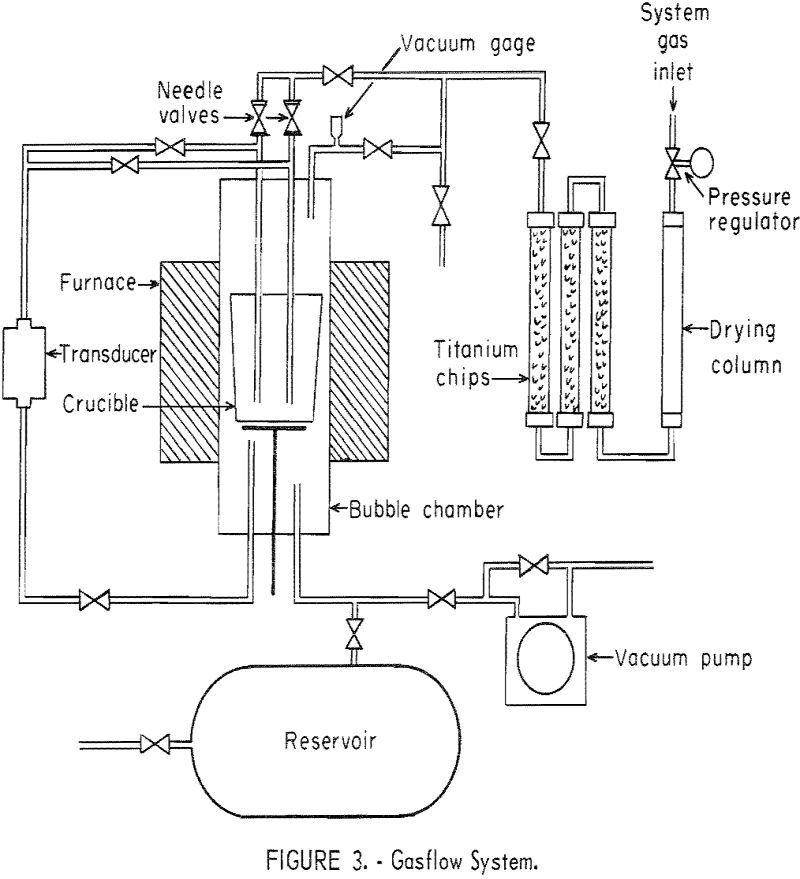

How to Measure Surface Tension of Molten Metals

We been performing research on soft soldering with the objective of improving the strength of solder joints at elevated temperatures and pressures. Surface or interfacial phenomena and the factors affecting these phenomena are of major importance in soldering and brazing. A knowledge of the surface tension of the molten materials involved, such as the filler […]

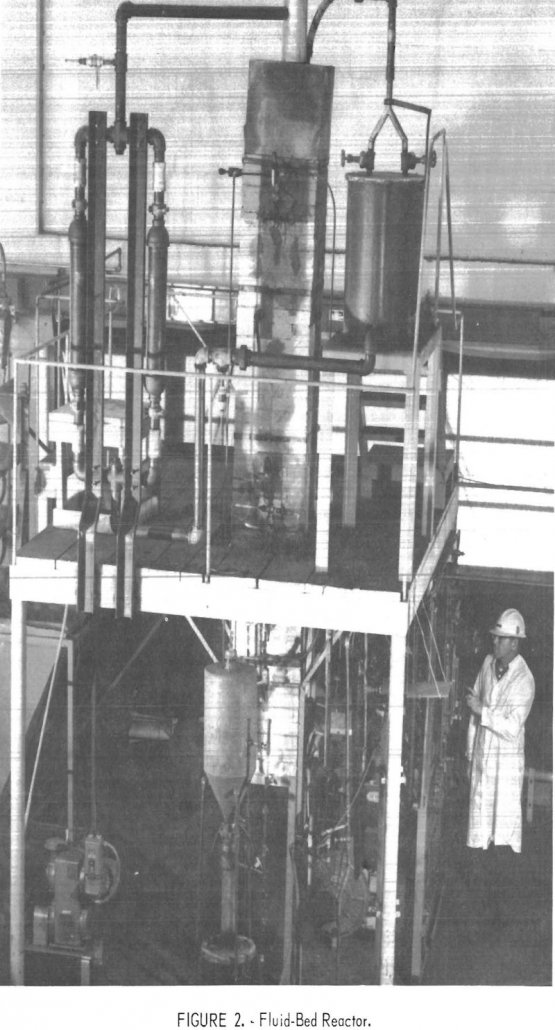

Chalcocite Oxidation Roasting

The Bureau of Mines Twin Cities Metallurgy Research Center is engaged in a study to uncover a cleaner, more direct pyrometallurgical process for winning copper from sulfides. The .initial target is low-sulfur concentrates containing primarily chalcocite (Cu2S). Development work, still in progress, points to a new and, perhaps, improved smelting procedure in which the following […]

Effect of Preheating Iron Ore Pellets

The production of pre-reduced iron ore pellets involves the expenditure of considerable capital and energy. Both prereduced and oxide pellets can be produced in similar equipment by using reducing and oxidizing processes, respectively. However, the throughput for a 5-m-ID by 50-m-long kiln with a preheating grate is 425,000 metric tons per year of ore, according […]

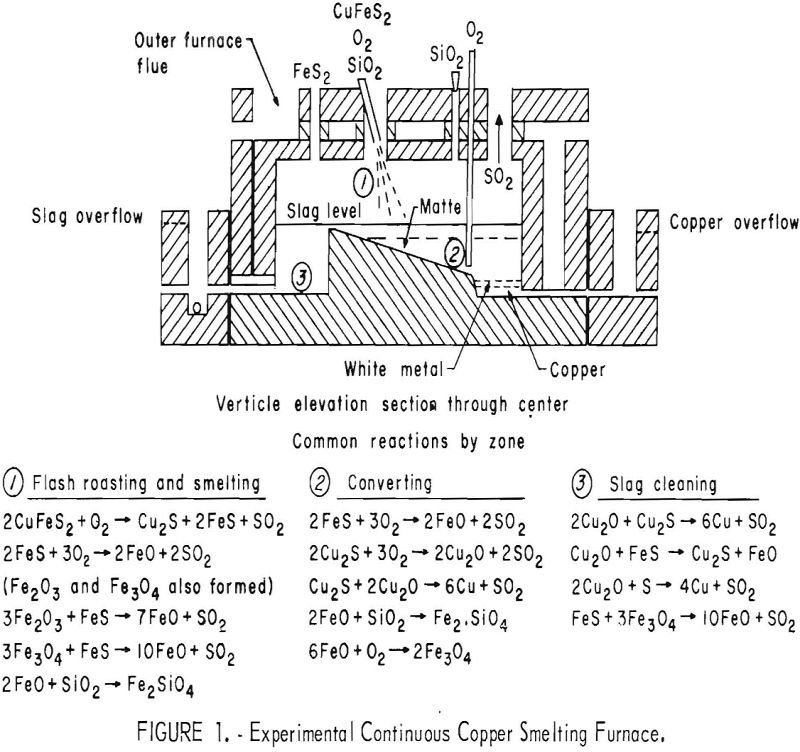

Copper Smelting

Throughout this century the major production of copper (as it relates to Copper Smelting) and most other nonferrous metals has been through pyrometallurgical methods, treating sulfide ores by various batch processes. The predominant copper process is reverberatory furnace smelting of sulfide concentrates to produce matte and slag, followed by treatment of the matte in converters […]

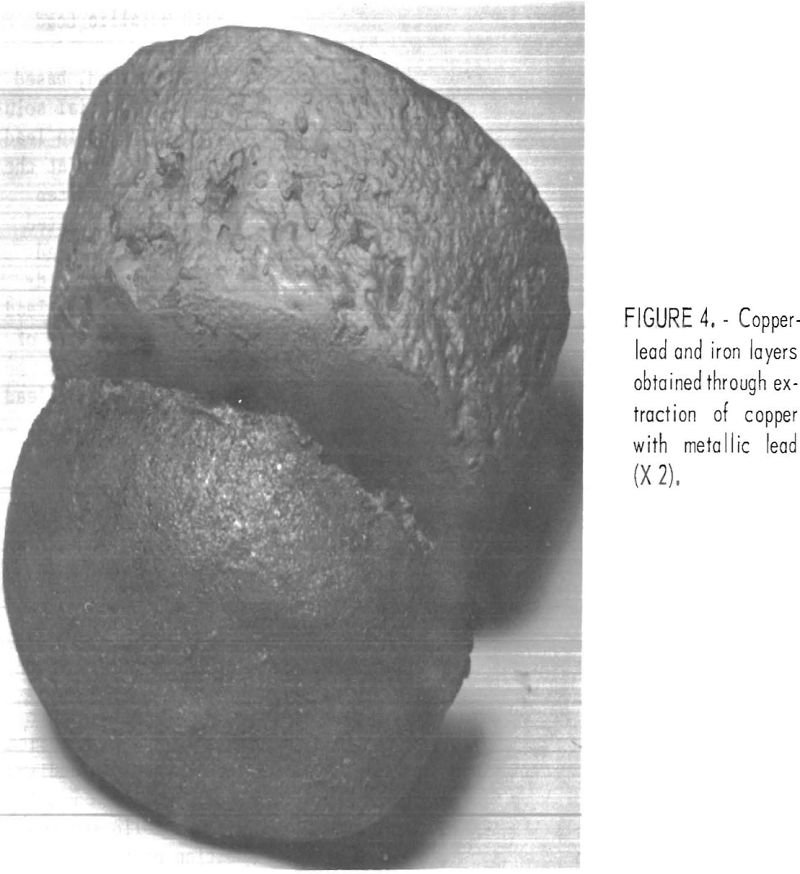

How to Recover Metals from Zinc Smelter Residue

Primary smelting of zinc in horizontal retort distillation furnaces leaves a residue consisting of the following: unburned carbon, iron as metal shot and stringers, copper inclusions in the iron as metal and as sulfides, silver in solid solution in the copper, and glassy slag. After removal from the retorts and cooling, the residue is crushed […]

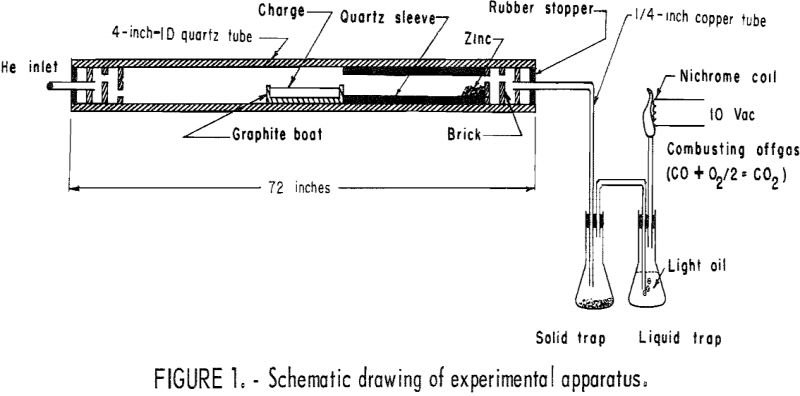

How to Recover Zinc & Lead from Brass Smelter Dust

The recovery and recycling of metals from process wastes is a major research effort of the Bureau of Mines. The present work was undertaken by the Rolla Metallurgy Research Center to develop data that could be used in a pyrometallurgical process to recover zinc and lead from the flue dust generated in the secondary smelting […]

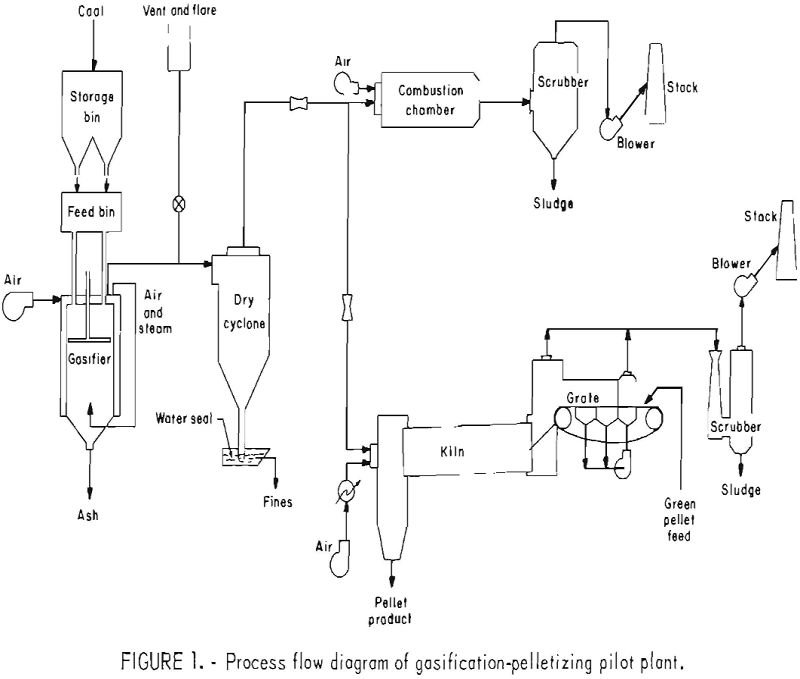

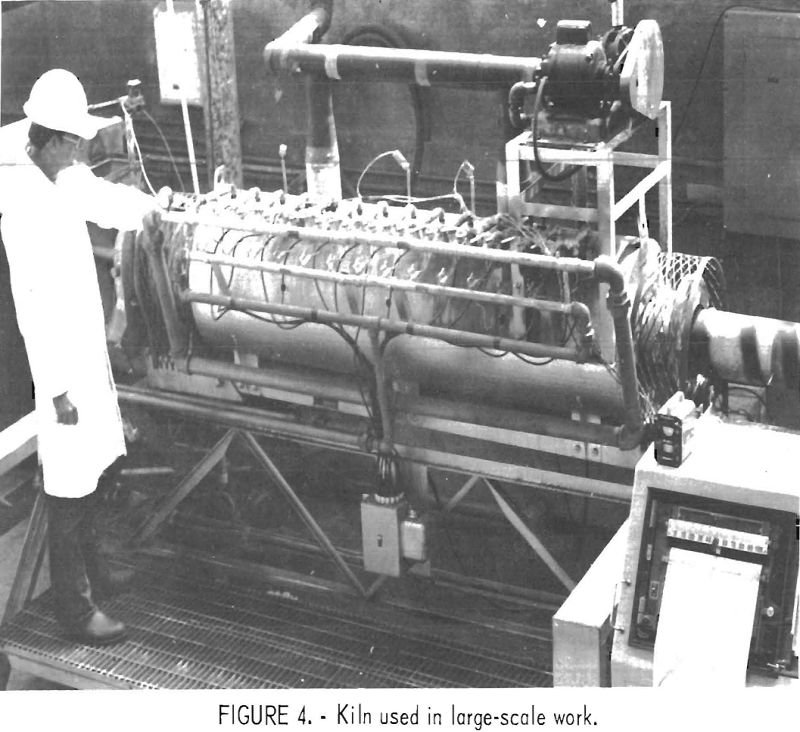

Gas Fired Iron Ore Pelletizing Kiln

The iron oxide pelletizing industry is very energy intensive and relies heavily on natural gas to fire pellet-indurating furnaces. Approximately 75 million long tons of iron oxide pellets are produced in the United States each year, requiring a fuel input of about 55 billion ft³ of natural gas. During the past several years the industry […]

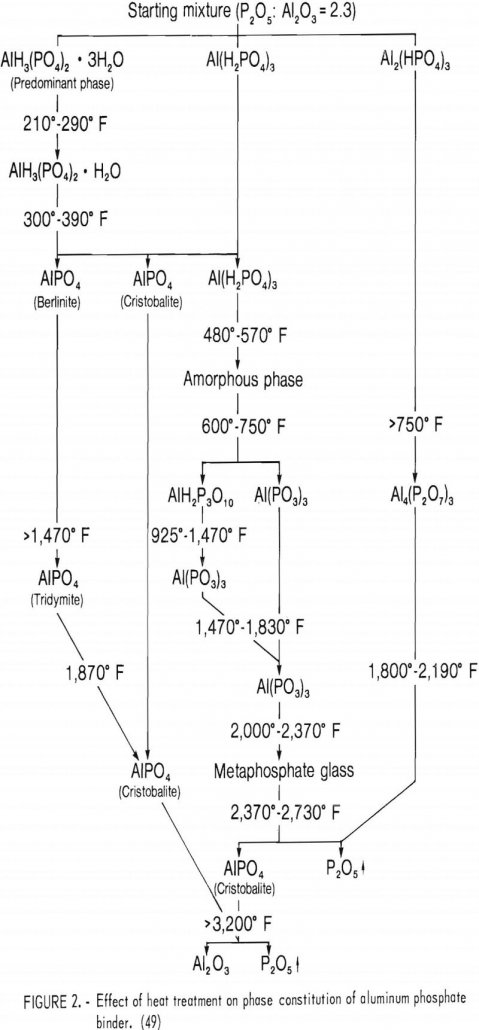

Chemically Bonded Refractories

Improved ceramic materials are in constant demand for processes involving severe chemical, corrosive, and thermal environments, especially at high pressures. During the past decade, demand for higher quality ceramic materials has significantly increased. This is true, for example, in the steel industry where oxygen steelmaking has increased production rates and operating temperatures, thereby compounding the […]

Leach Chalcopyrite using Lime Roasting Process

Most copper is now produced from chalcopyrite flotation concentrate by smelting. While smelting achieves high recoveries of metal values at a reasonable cost, it is responsible for the discharge of large amounts of SO2 to the atmosphere. Roaster gases and, occasionally, converter gases are processed to obtain sulfuric acid, but gases from reverberatory furnaces, which […]

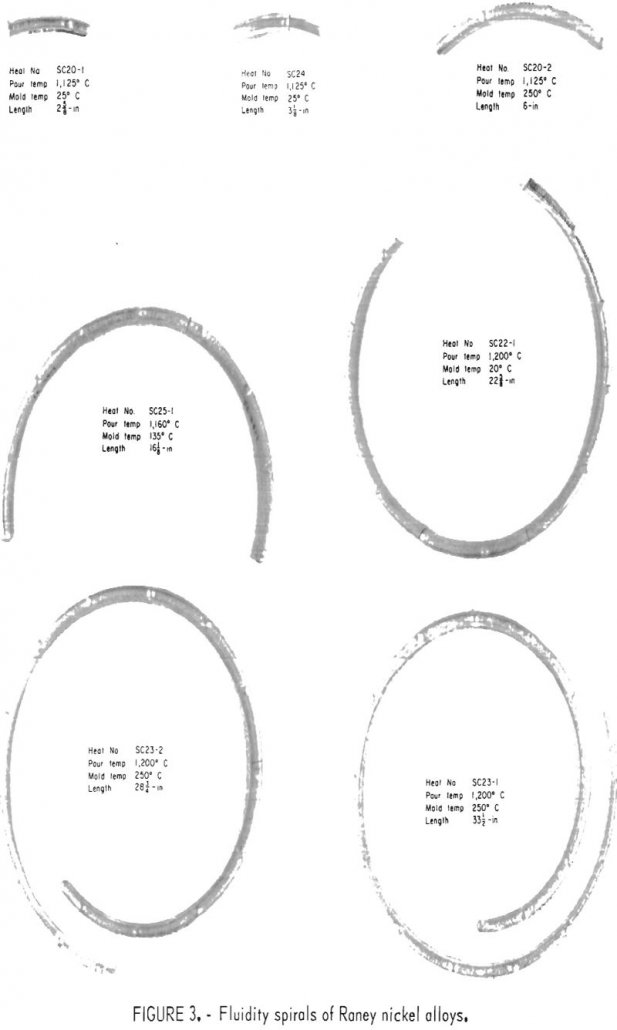

Raney Nickel Alloy Melting and Casting

The conversion of coal into a high-Btu gas as a means of augmenting existing supplies of natural gas has been the subject of much research. The Bureau of Mines has played an active role in this area and has developed the Synthane process. The Synthane process consists of reacting coal, steam, and oxygen in a […]