Underground Mine Design

The minerals industry in the field of Underground Mine Design is presently faced with the problem of meeting a rapidly increasing domestic and foreign demand for its mineral resources. This increased demand has added to the problems already plaguing the industry increased land, labor, and material costs; increased foreign competition; more rigid Federal and State […]

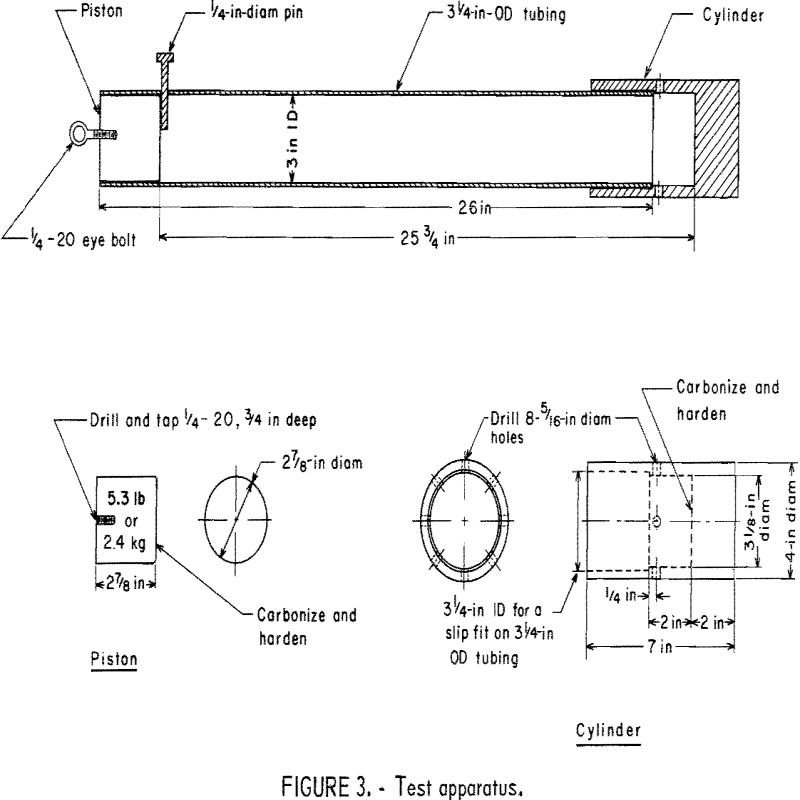

Rock Testing Procedure

Design engineers involved with mine or tunnel construction require knowledge of rock behavior in order to assure economic excavation of rock and stability of underground openings. For many applications, the behavior of a rock is determined from an engineering approach involving rather empirical experiments. A greater emphasis is now being placed on the use of […]

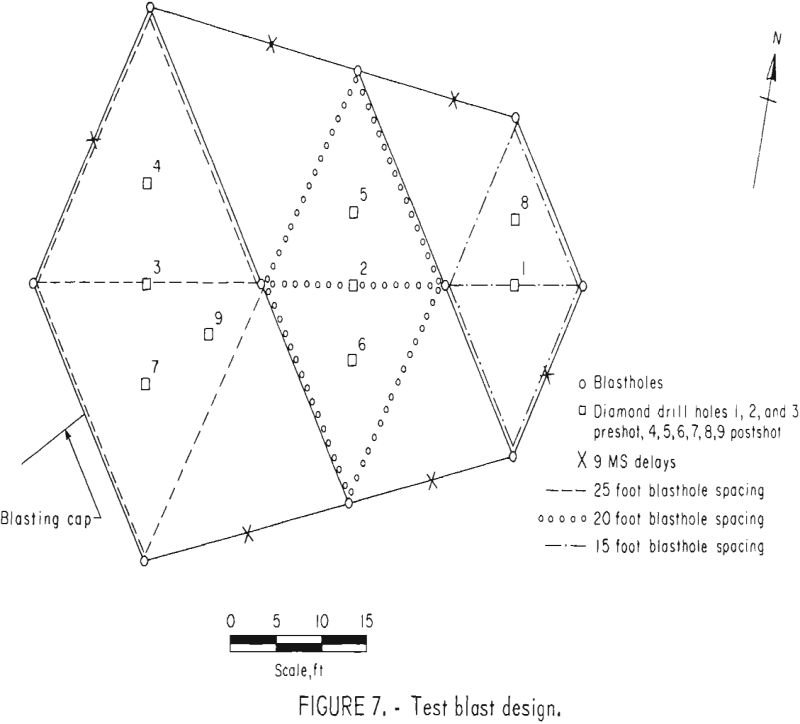

Porphyry Copper Blasting

Some are developing fragmentation technology for in situ extraction systems. An in situ extraction system is attractive because it can be applied to deposits that are presently too low grade to be mined by conventional methods, thereby increasing domestic reserves. In situ extraction also reduces exposure of workers to health and safety hazards, minimizes detrimental […]

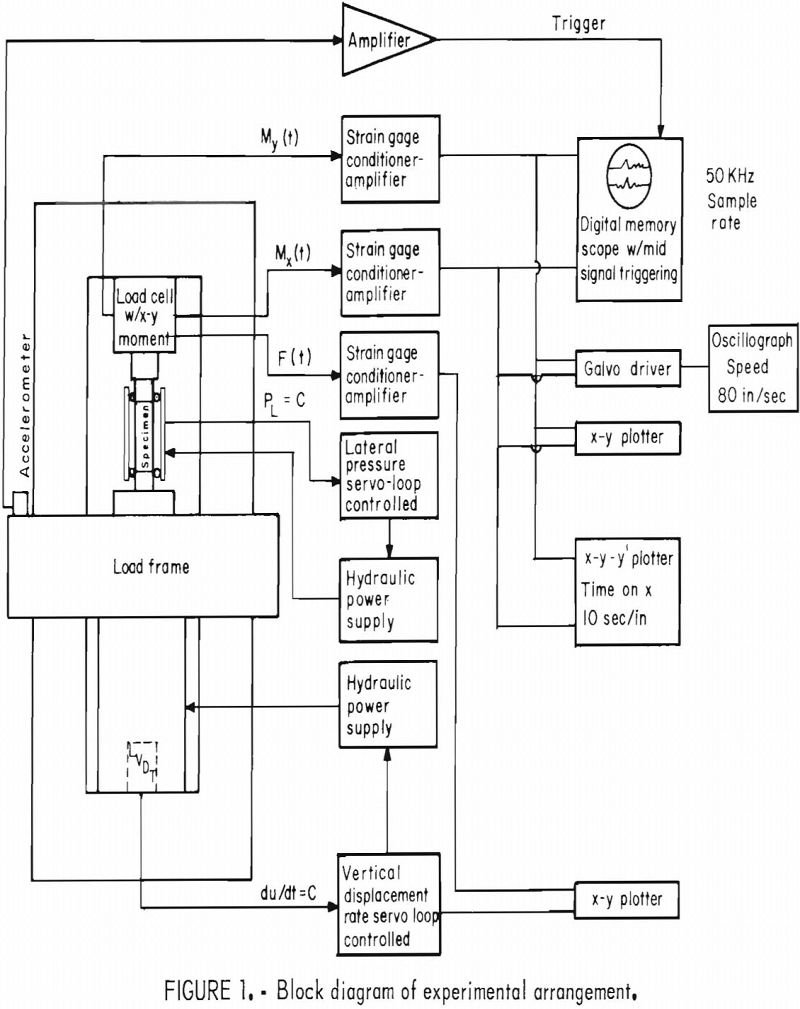

Rock Failure Tilt Precursors

A scale-invariant theory of rock failure has been proposed that predicts precursor effects prior to failure, such as anomalous VP/VS behavior and tilt, will occur in either dry or wet rock. Because the theory is scale invariant, these effects are predicted to occur on the laboratory scale over a time interval of a few milliseconds […]

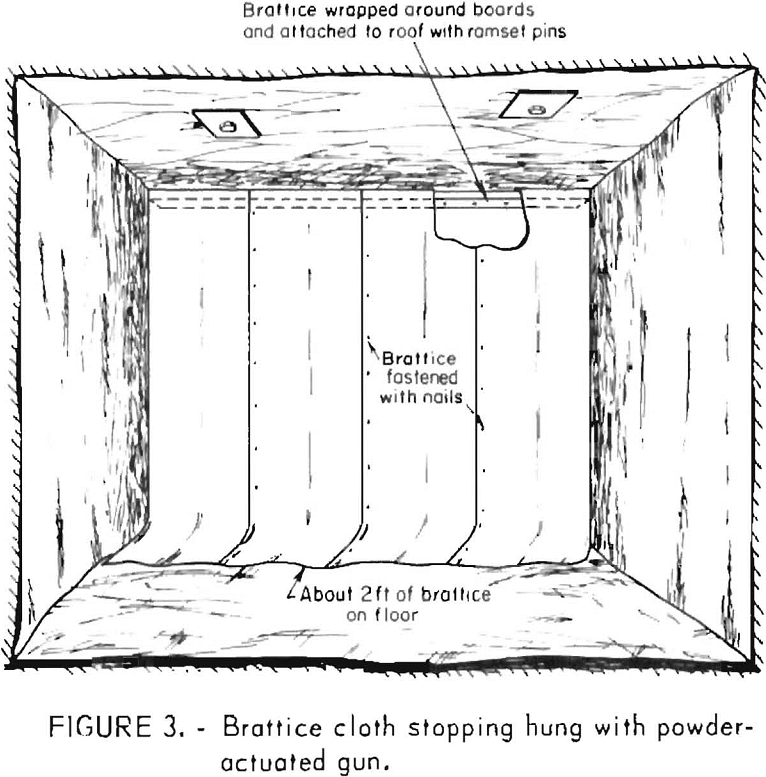

Mine Stoppings

Most of the mines with large openings in the United States today are salt and limestone mines. Some potash and trona mines also have moderately large openings. Moreover, it is expected that in the near future numerous underground oil shale mines will be developed in the oil shale regions of Colorado, Utah, and Wyoming. These […]

Drillability Index

Cost is a major criterion in decision making for selecting operational methods in mining. Knowledge of the operating cost, therefore, provides a sound basis for evaluating the feasibility of plans and for selecting alternative operational procedures. In production drilling, the choice of a drilling method is primarily based on several factors such as working condition, […]

Conveyor Design for Mining Machines

It does not appear likely that this conveyor-system function requirement can be avoided. The emphasis on the continuous miner performance is necessarily such that the conveyor system must be required to handle any material that is provided by the cutting head. Hence, a slowing down in the rate of advance of the miner to produce […]

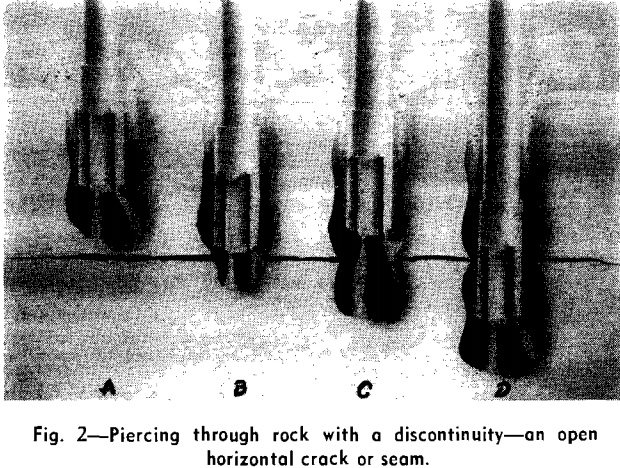

Jet-Piercing

During 1950 the jet-piercing process was used commercially in the piercing of primary blast-holes in magnetic taconite at the preliminary taconite plant of the Erie Mining Co., Aurora, Minn. To produce the blasthole, jet-piercing utilizes thermal energy, as contrasted with the application of mechanical energy in churn drills and jackhammers. The heart of the process […]

How to Operate a Small Scale Mine

Any mining engineer with a desire to operate independently, with some financial backing, and with no fear of heavy responsibility and long hours, should be able to make a comfortable living in Mexico. Barring a few inconveniences such as a lack of satisfactory liability or accident insurance, the difficulty of obtaining repair parts for vehicles, […]

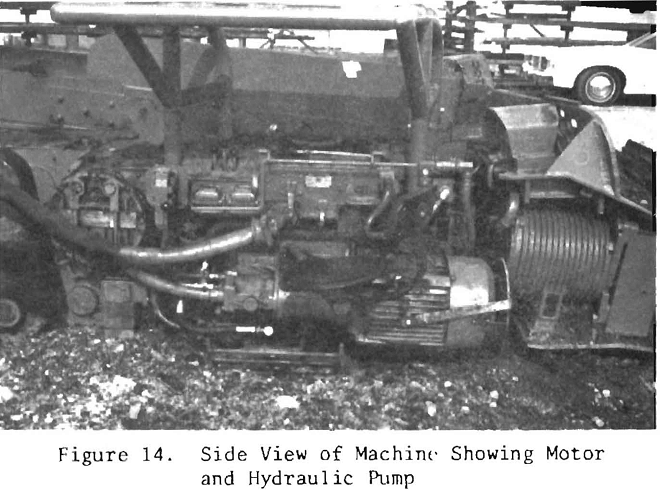

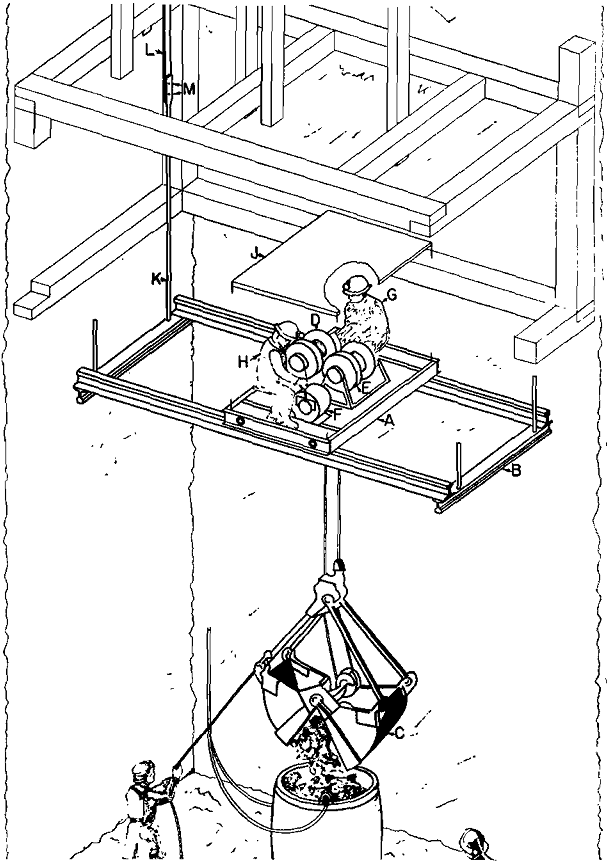

Shaft Mucking Machines

Hand mucking in shaft sinking operations is no longer necessary because several efficient methods and machines have been devised for this purpose for use in both vertical and inclined shafts. For years shaft sinking was considered the hardest and most dangerous job in mining and, consequently, the turnover in shaft crew was high. High turnover […]