Method of Evaluating Magnetic Separator Force Patterns

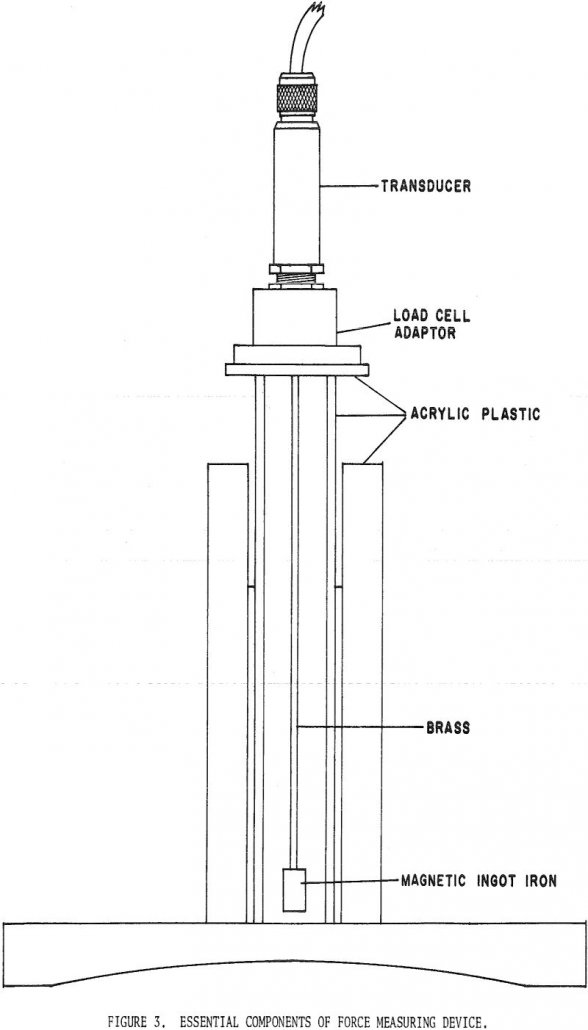

One of the problems facing both the designer and the user of magnetic separators is the evaluation of the body forces acting on particles in the magnetic field of the separator. Perhaps the most elegant method of evaluating the body force associated with a drum-type magnetic separator. Once the coefficients of the series are known, […]

Separation of Solids and Fluids by Magnetic Flocculation

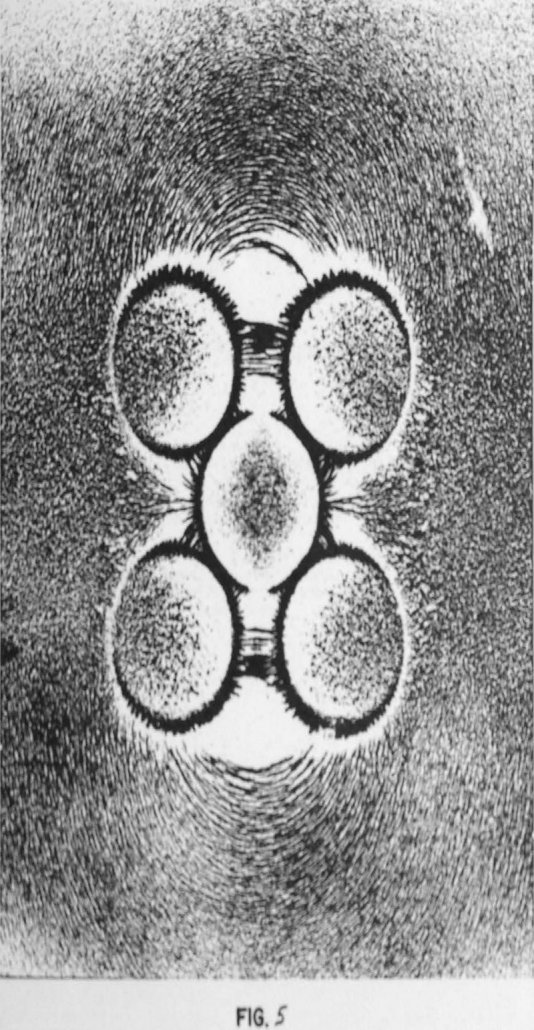

Flocculation, the process of coagulation or coalescence of finely divided particles, is commonly used in separating fine solids from fluids. Forces disposing of the particles to flocculate include: ionic forces of attraction, secondary entropic forces, and magnetism. Magnetic flocculation is due to a physical magnetizing process which affects suspended ferromagnetic particles. Such particles, after exposure […]

Magneto-Gravimetric Separation of Nonmagnetic Solids

Stable colloidal solutions of ferromagnetic or ferrimagnetic materials are called magnetic fluids. About two generations ago, suspensions of relatively large micron-sized ferromagnetic particles in oil proved useful in clutches, brakes, and dashpots. They were called magnetic clutch materials, and their viscosities were highly dependent upon the applied magnetic field. Magnetic colloids, by contrast, are especially […]

Wet Magnetic Separation

In essence, any magnetic separator operates on the basis of imparting a preferential magnetic force on particles of higher magnetic susceptibility which are to be separated from particles of lower magnetic susceptibility. A certain amount of directional deviation to the particles takes place thus allowing for collecting each category of particles separately. Under fixed […]

Recovery of Aluminum by High Tension Separation

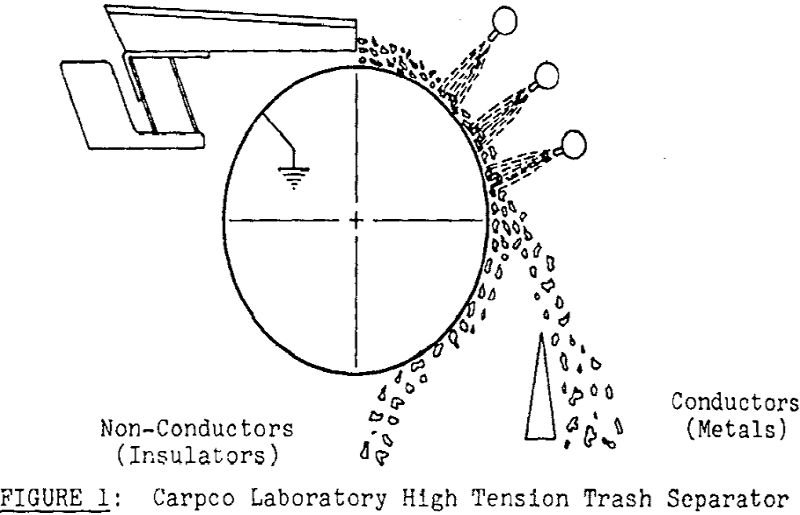

The high tension process which separates materials based on relative differences in surface conductivity has been very successful in recovering non-ferrous metals from municipal waste. Aluminum is by far the largest constituent of the total non-ferrous metal fraction; accounting for >95% in most localities. Wire and insulation mixtures from industrial wastes have been treated commercially […]

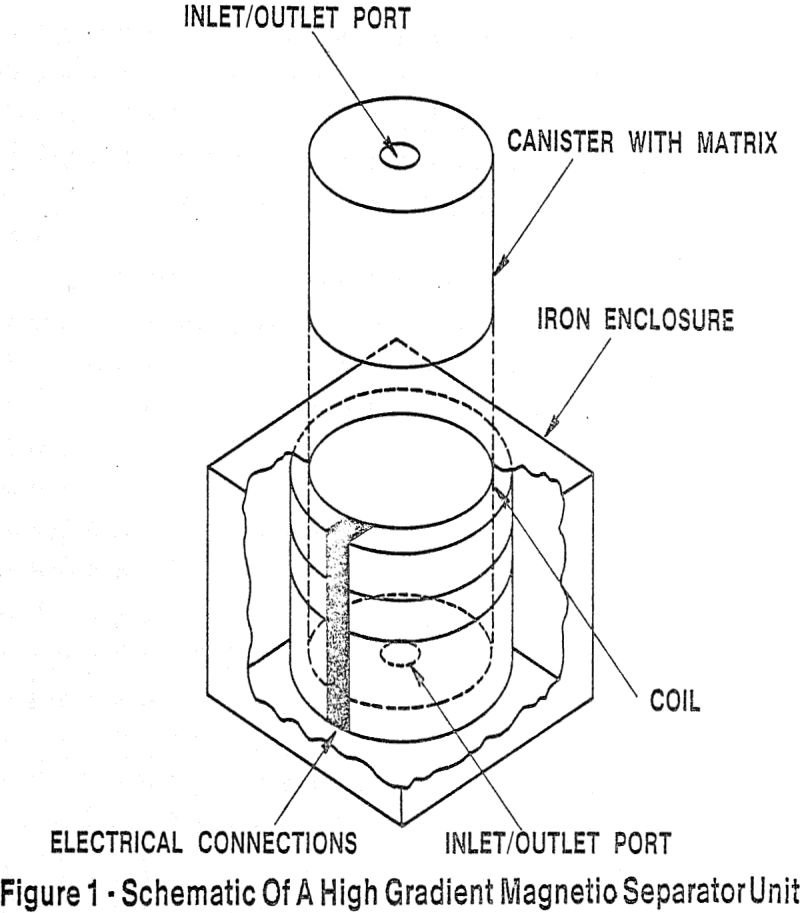

High Gradient Magnetic Separator

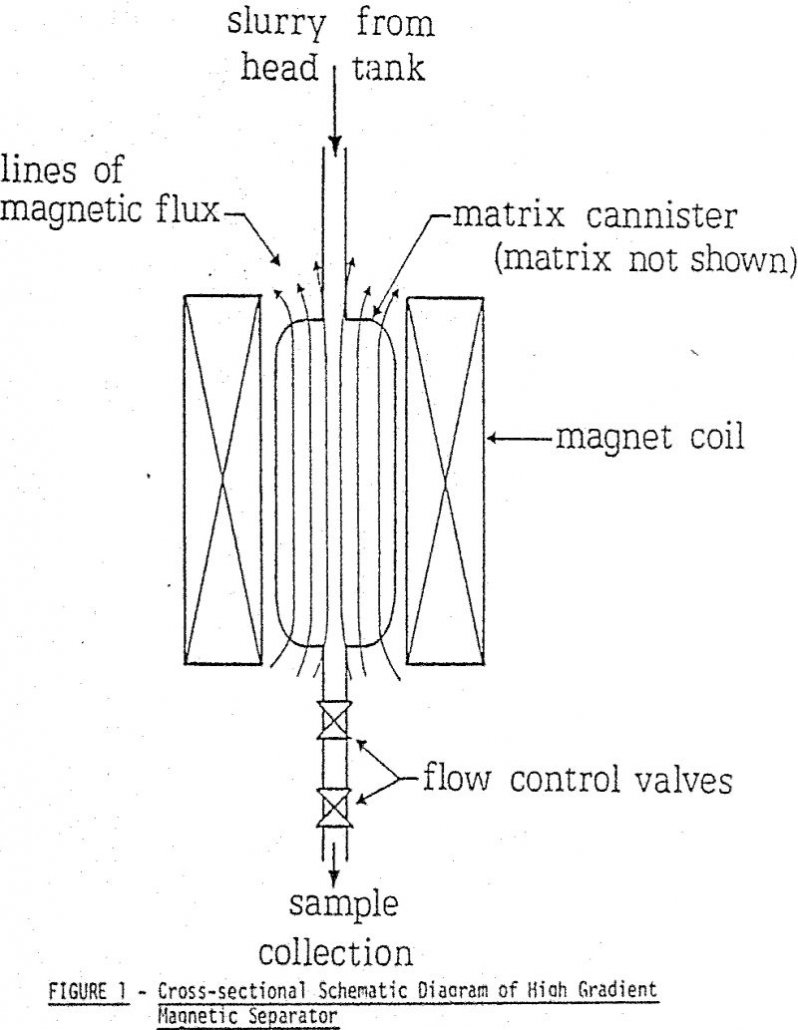

High-intensity wet magnetic separators have been successfully introduced into, the mineral processing field over the past ten to fifteen years, due largely to rapid advancements in magnet design. Wet magnetic separation, until recent years, was applied solely to the concentration of minerals of high magnetic susceptibility, such as magnetite, at relatively coarse sizes. Now, however, […]

High Gradient Magnetic Separation of Uranium Ores

Continuing interest in processes that will effect separations in the fine particle size range has prompted intense interest in the use of high gradient magnetic separation (HGMS) for beneficiation of uranium ores. Some of the uranium minerals are paramagnetic and hence are amenable to concentration by HGMS. HGMS is a powerful method in the upgrading […]

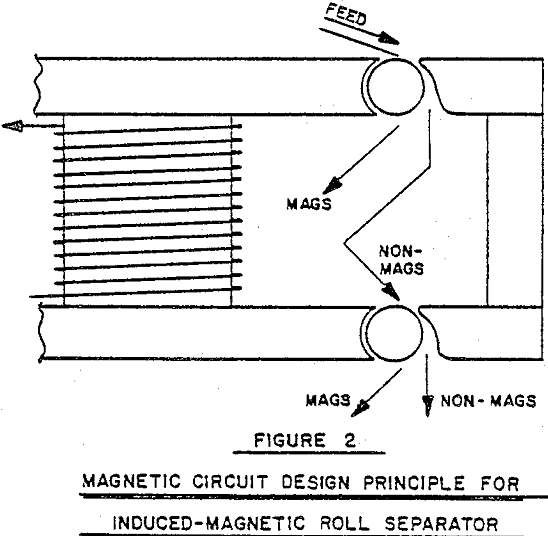

High-Intensity Roll Separator Using Permanent Magnets

High-energy product permanent-magnet materials of rare-earth cobalt alloys are being used in applications where space or weight are at a premium cost. New applications like friction-free bearings are also made possible. However, such magnet materials have not been commercially used in magnetic separators until now due to the high cost for the overall magnetic flux […]

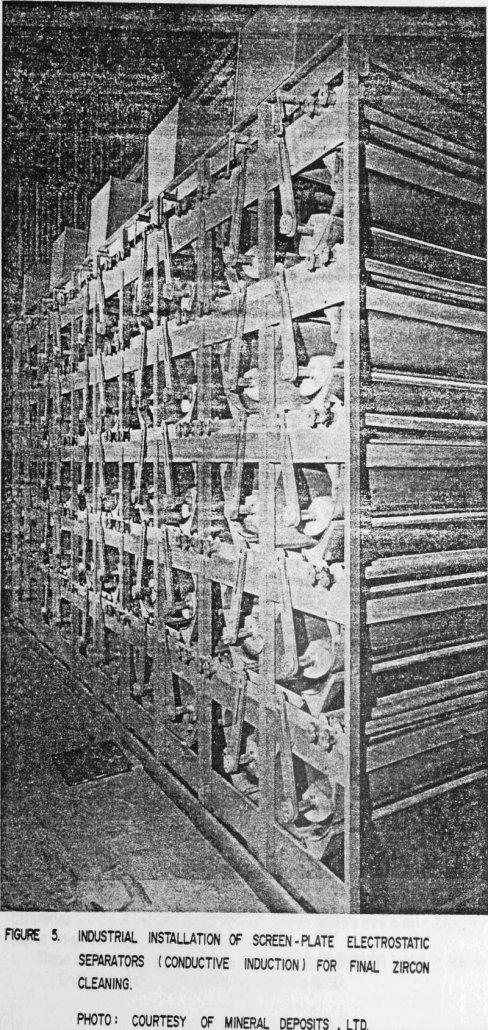

Electrostatic Separation

Electrostatic separation is one of the most misunderstood physical processes used to beneficiate minerals. Nonetheless, millions of tons of titanium ores, iron ores and other minerals are processed every year economically, efficiently and safely. Over the past ten years major advances in electrostatic separation and its application have occurred. New processes include dewatering clay slurries, […]

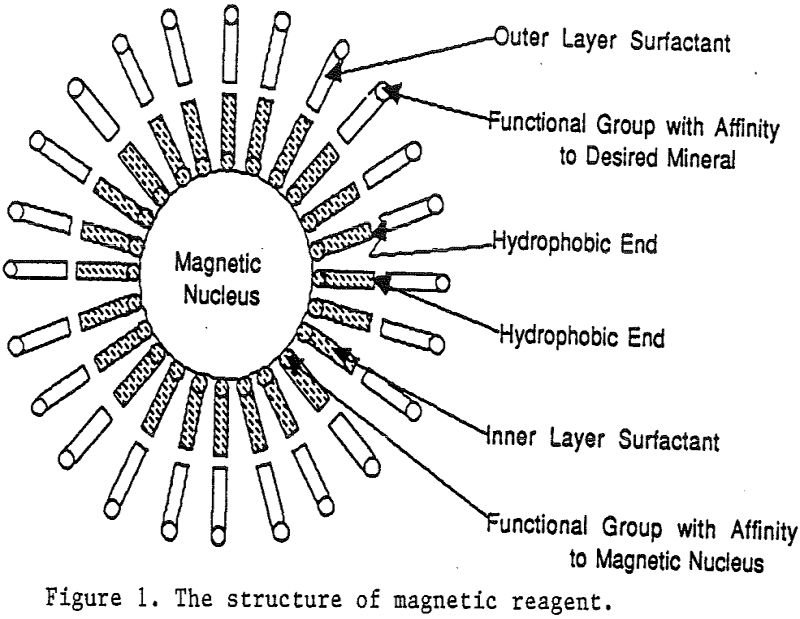

Magnetic Reagents

The behavior of fine mineral particles in a slurry is difficult to control, presenting a serious problem in many processes. At fine particle sizes, gravitational force is weak. Electrostatic force, although strong in dry conditions, can rarely be applied for particles in an aqueous slurry. The applications for using magnetic force are limited because most […]