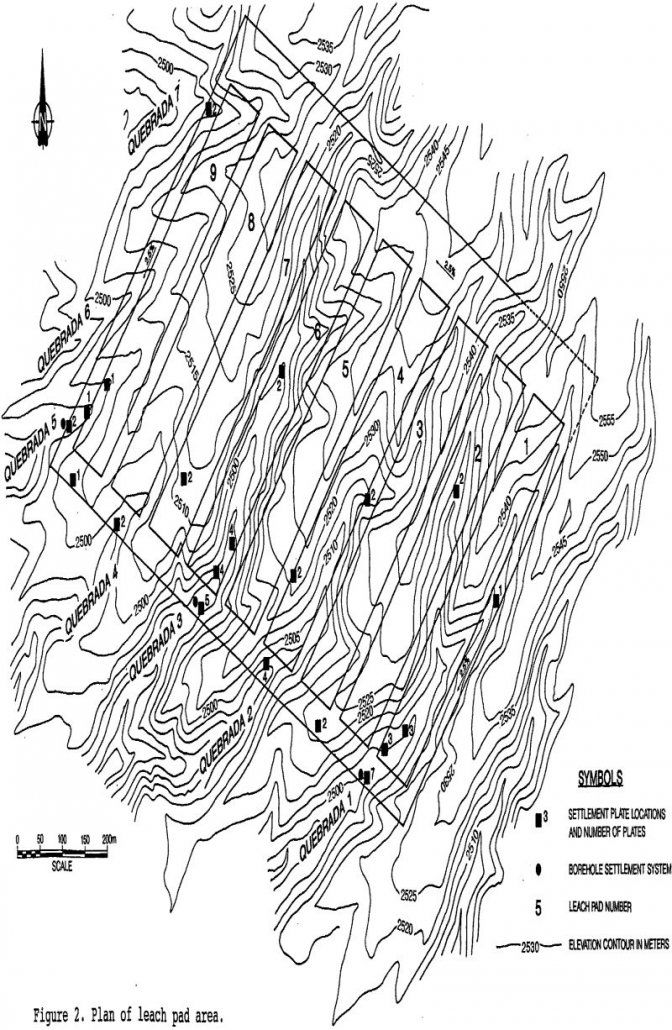

Geotechnical & Construction Aspects of ON OFF Leach Pad

Project Description Exploration and development of the project by Rio Algom Ltd. began in 1981. Feasibility and design studies were ongoing in the 1980’s culminating in a decision to develop an open pit mine, a heap leaching facility and an SX-EW plant capable of producing 60,000 tonnes of fine copper per year. Construction began in […]

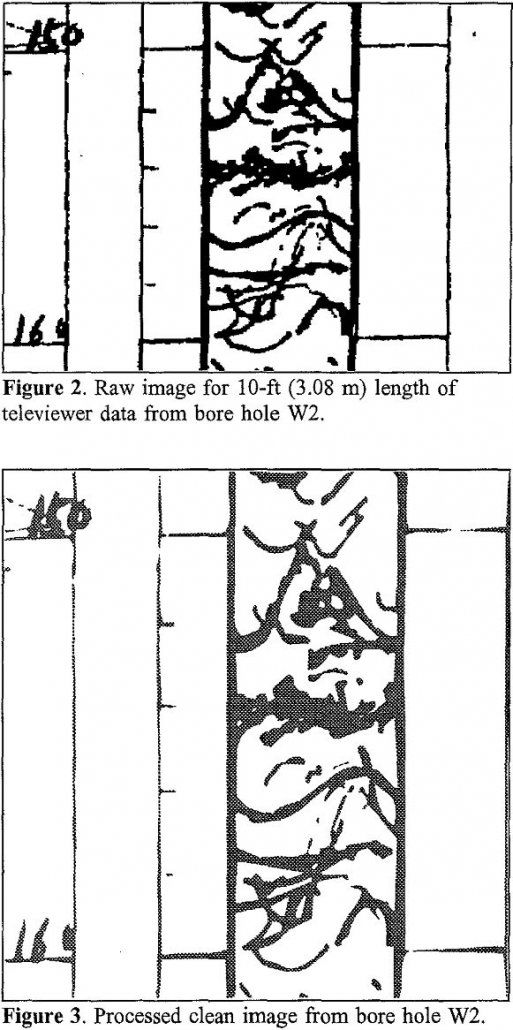

Percolation to Enhance In Situ Copper Leaching

A numerical model is being developed to assess the enhancement of permeability by improved fracture connectivity by micro-hydrofracturing. A generic two-dimensional percolation model has been developed to test the impact of various field conditions on permeability. Field data from Cyprus Minerals’ Mineral Park Mine has been used to establish statistical properties of the observed fracture […]

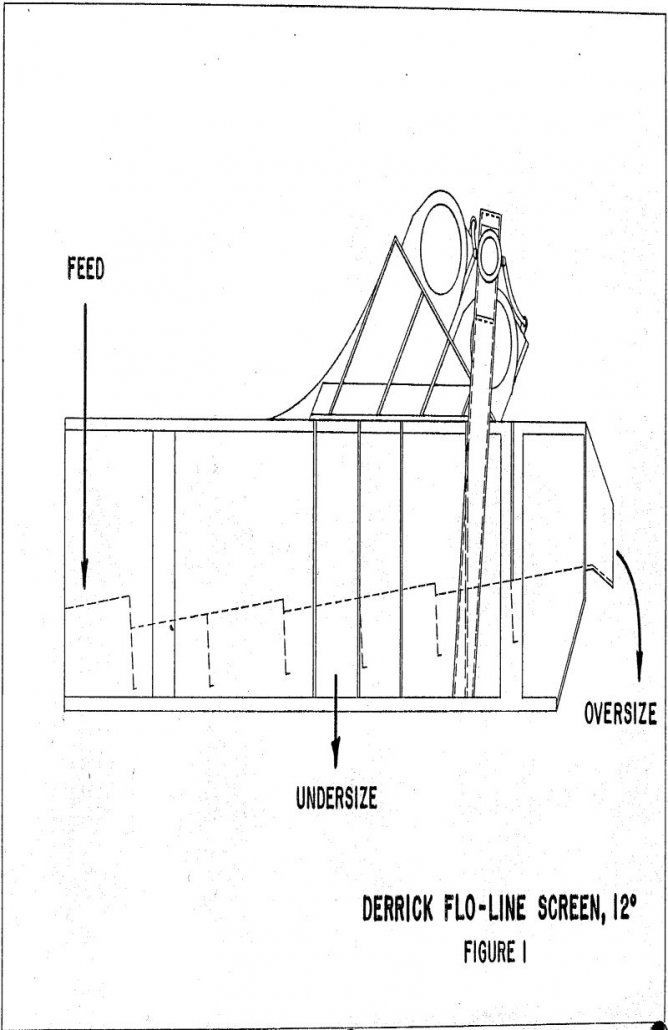

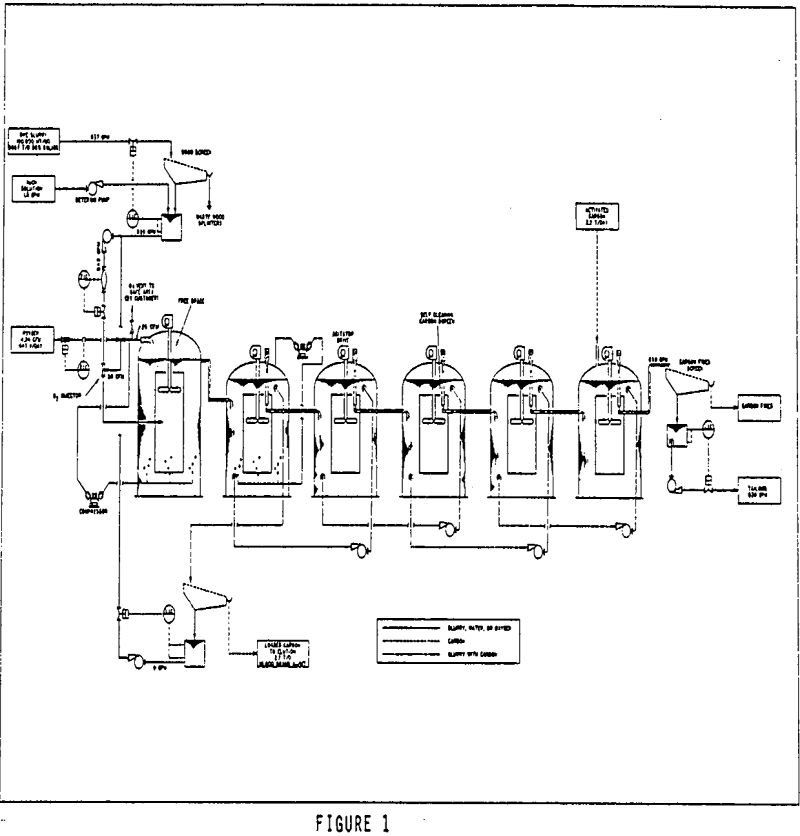

Carbon In Pulp Screening using High Frequency Screens

Mechanical Development – Laboratory Testwork Derrick Manufacturing Corporation originally developed the 1.22m x 2.44m Flo-line screen for rock chip removal from drilling muds. It features a 3° reverse angle deck slope and is powered by dual 1.1 kW TENV motors rotating in opposite directions. Figure 1. Screen feed enters from the lower end and, due […]

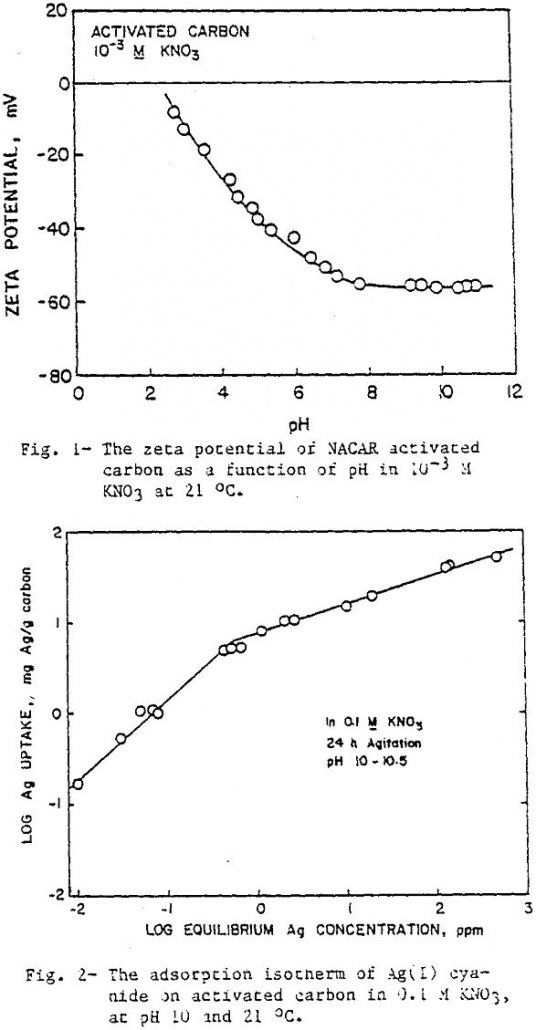

Adsorption of Silver Cyanide on Activated Carbon

The Nature of Activated Carbon “Activated carbon” or “activated charcoal” is a generic term applied to amorphous carbon materials that have adsorptive capability. These materials are made from different sources and are available as powder, pellets, or grains. Their common characteristic is a very large surface area in the range of 600 to 1200 m²/g […]

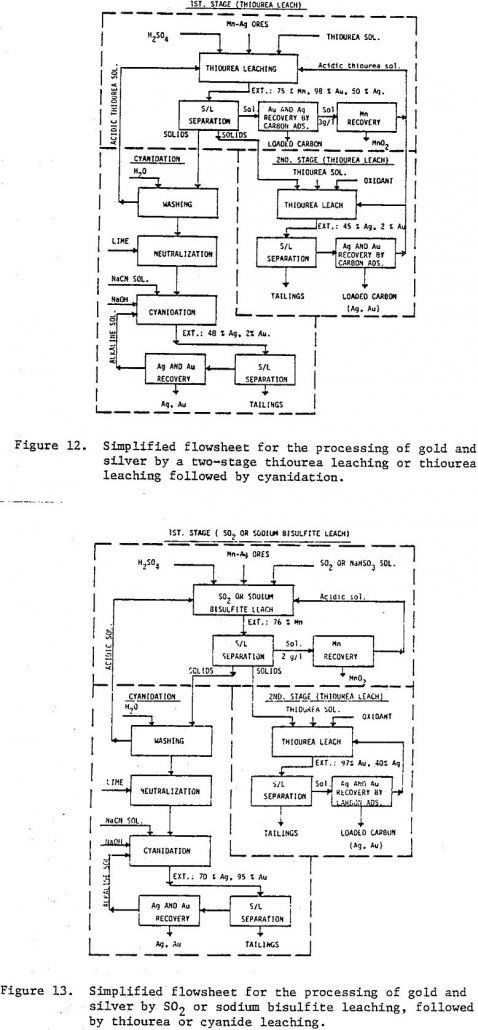

Thiourea for Extraction of Gold & Silver from Silver Ores

Leaching Chemistry of Gold Silver and Manganese Thiourea is a reducing and complexing agent and can be used for the processing of gold and silver. The redox potential of gold(I) and silver(I) thiourea complexes in acidic thiourea solutions are 0.380 and 0.023 V (vs SHE), respectively (Kazakov et al., 1983; Lodeishchikov et al., 1975). Thiourea, […]

Carbon in Leach with Oxygen CILO Process for Gold Ores

This paper describes a new development in the cyanidation of gold ores, which we expect will result in a major improvement in the way many gold ores are treated. The process has evolved through work at Hazen Research, Inc. for Kamyr, Inc. and in brief, the consists of utilizing oxygen rather than air in the […]

Copper Oxide In-Situ Leaching Wellfield Design

Copper oxide deposits that may be considered for in situ leaching exist in unique geologic settings, different from uranium deposits. A large number of interrelated factors must be considered in wellfield design. Many of these factors are hard to quantify and are directly related to geologic features of the orebody. This paper discusses some of […]

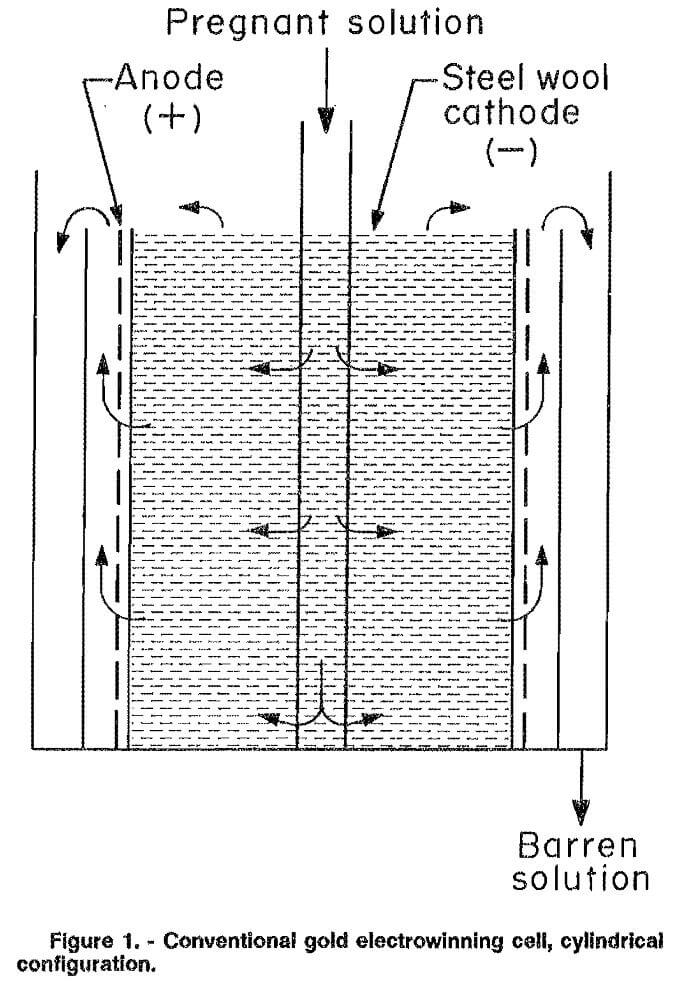

Electrowinning Mercury in Gold Pregnant Solution

Many gold-bearing ores in the Western United States also contain small amounts of mercury. The presence of mercury creates potential pollution and health hazards during several steps in gold processing. An investigation was undertaken by the Bureau of Mines to develop techniques for removing mercury from cyanide mill solutions by selective electrowinning to reduce the […]

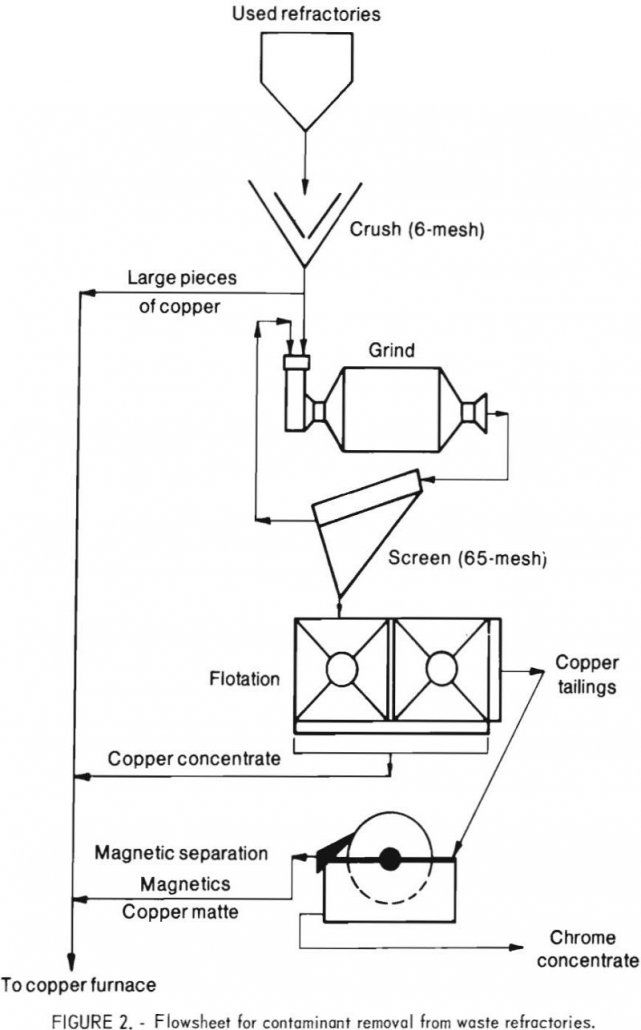

How to Recycle Magnesite Chrome in Copper Smelting Furnaces

In accordance with its objective to maximize minerals recovery from secondary domestic resources, Bureau of Mines conducted research on recycling chrome refractory wastes. Since 20 pct of the U.S. demand for imported chromite is used in the production of refractories, primarily for the steel, copper, and glass industries, samples of used chrome-containing refractories from copper […]

Carbon in Pulp Plant

Sslurry at a rate of approximately 3.785 cu. m. per minute (1,000 GPM) is placed in contact with activated carbon. A simplified flow-sheet of the CIP Plant is shown in Figure 2. For years it has been known of the affinity of activated carbon to adsorb preferentially the gold and silver in cyanide complex form. […]