Peripheral Discharge Ball Mills -Theory and Practice

These notes are based on observations made while on a recent trip through the West, for the purpose of studying the practical operation of the ball-mill. The writer takes this opportunity to express his thanks for courtesies extended at the many plants visited as well as for the valuable data received. While there are several […]

Flotation & Shaking Tables with Open Circuit Ball Mill

DESCRIPTION: Flotation followed by shaker table concentration in open circuit grinding. ORE TREATED: When the mineral in an ore is freed at a coarse mesh, this flowsheet gives high recovery and high capacity. The practice is limited in scope, as on ores requiring fine grinding, closed circuit is preferable, and on ores wherein the gold is free, amalgamation […]

Grinding Circuit Startup and Shutdown Procedure

Ball Mill Trunnion Bearing Lube System

On a 11’-6” x 22’-0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during start-up of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature […]

Ball Mill Liner Design

There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected. Based upon individual experience, mill superintendents develop preferences for liner designs. The following is given […]

Rods or Balls

Mill operators will not get to design too many mills, but this doesn’t mean that the information that has been compiled isn’t of interest to the operator. Knowing the ore body shape, size, and content will give the operator prior knowledge of operating conditions to be expected. It is also beneficial to know how this […]

Indice de Trabajo de Bond y su Procedimiento

El índice de trabajo de Bond se ha usado por muchos años para indicar el consumo de energía de un molino de bolas para obtener un tamaño de partícula deseado, usualmente expresada como el pasante bajo una malla especifica como la 150 o la 200.el valor del índice de trabajo de trabajo es una característica […]

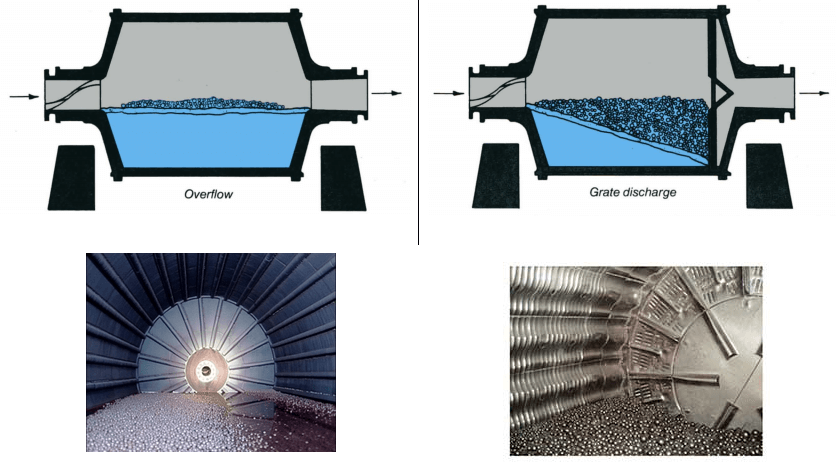

Overflow VS Grate Discharge Ball or Mill – Why Retrofit

Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is wanted, without any respect to the particle size distribution curve. Overflow discharge mills give a final product in an open circuit. Grate discharge mills are used when the […]

Conical Ball Mills Benefits & Advantages: Hardinge

The generally recognized fact that for economic reduction of any material, it is desirable to perform such reduction in steps or stages, removing that material which is sufficiently fine as soon as it is reduced and grinding it still finer in some device more adaptable to this finer reduction. It has been found that by […]

Rods-Balls