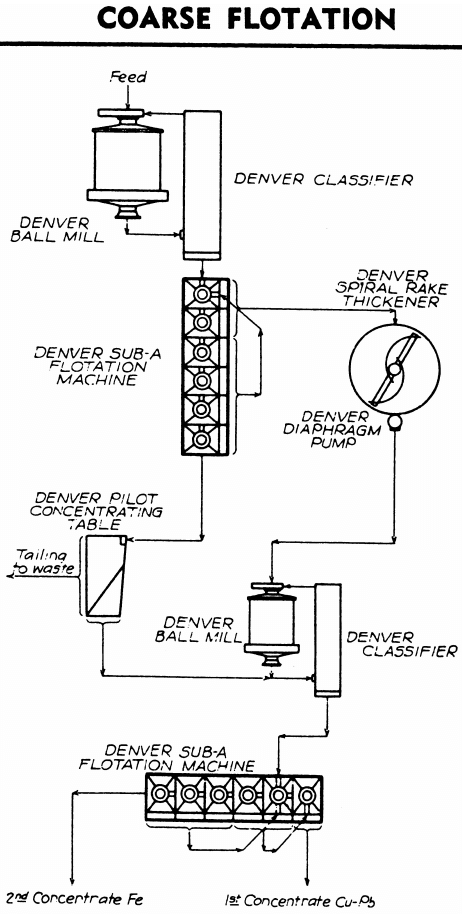

Coarse Flotation with Gravity & Regrind Circuit

DESCRIPTION: Coarse flotation followed by regrind of coarse rougher concentrate and selective flotation or cleaning. Coarse flotation tailings and reground rougher concentrate are processed over a shaking table for precious metals. ORE TREATED: Ores wherein the minerals can be freed from the gangue at a coarse mesh and subsequently separated from each other after finer grinding. […]

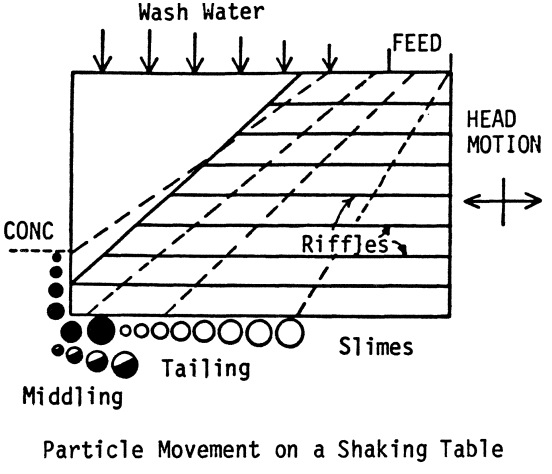

Diagonal Plane Shaking Table Design

Recent experiments indicate that the usual type of gold concentrating-table is not only poorly adapted to produce the desired results, but also is based upon an incorrect principle, namely, the use of riffles to perform the work of stratifying the various minerals. We have heard a good deal about riffles for concentrating-tables; exhaustive experiments have been […]

Stamp Mill Animation

When stamp mills are used for dry crushing, double discharge mortars are provided (see Fig. 50), and the screens are put low down, giving a small depth of discharge. These arrangements are necessitated by the difficulty of discharging the crushed ore from the mortar, the only means of doing this being the dashing of the […]

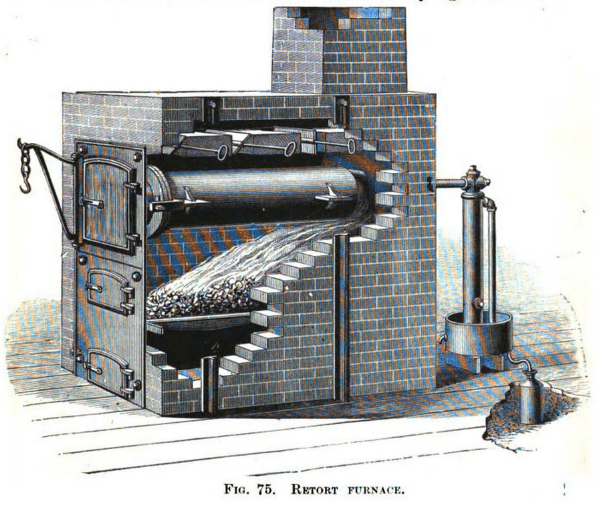

Retort Furnace, Retorting Pot & Condensing Pipe

This retort furnace, is an improvement on those formerly constructed. It has three dampers for directing the flames and heat from back to the front end of the retort. As the entire retort and its cover is within the furnace the mercury is equally driven off from all parts of the amalgam, leaving the whole mass […]

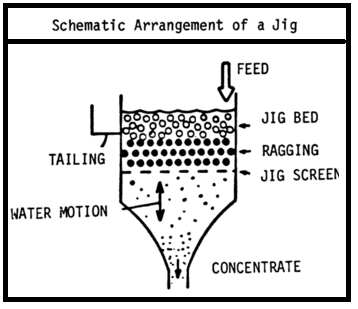

Gold Jig & Mineral Processing Jigs

The Gold Jig or Mineral Jigs are important of all types of alluvial gold concentrating device among all gravity separation methods; they are also the most complex and the practice of jigging in mineral processing is often viewed as an art rather than a science. Gold jigging has been referred to as being probably the most complex gravity operation because […]

Gold Shaking Table

A Gold Shaking Table are basically low-capacity machines used as last step in the gold upgrading process. The shaking table is a thin film, shear flow process equipment, that separates particle grains of its feed material based on the differences in their specific gravity, density, size and shape. Mineral rich particles, from light to heavy and fine to coarse will […]

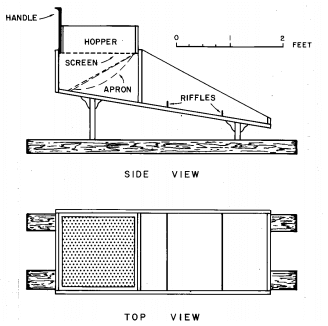

Concentrating Table

For running laboratory tests on a small scale, a laboratory size Wilfley Concentrating Table is an indispensable unit. The action of the Wilfley Laboratory Concentrating Table duplicates that of the commercial units and laboratory results can be accurately reproduced in commercial operation. This laboratory table is also used extensively as a pilot table to indicate the efficiency […]

Healthy Gold Shaker Table

https://www.911metallurgist.com/gold-shaking-tables https://www.911metallurgist.com/gold-shaker-table-plans

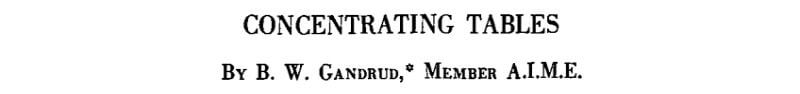

Gold Rocker Box

One of the first devices used after the gold pan was the gold rocker box. The rocker allowed small operators to increase the amount of gravel handled in a shift, with a minimum investment in equipment. Rockers vary in size, shape, and general construction, depending upon available construction materials, size of gold recovered, and the […]

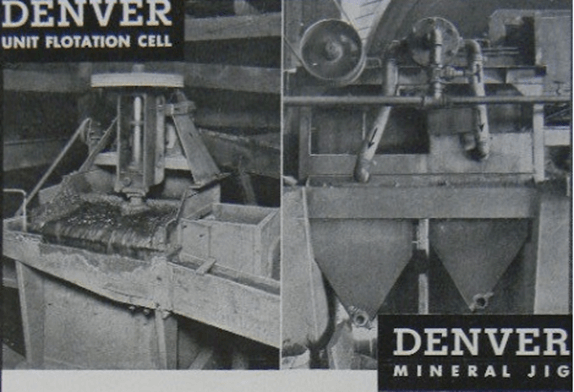

Flotation and Gravity for Better Recovery

HIGHER RECOVERIES ALWAYS RESULT when freed mineral is removed from the fine grinding circuit. Here are the two profit making machines which have today made this step standard practice in milling plants the world over. The Denver unit Flotation cell has definite place in every flotation plant where lead, copper, zinc or other sulphides are […]