Laboratory Amalgamation Equipment

Laboratory Amalgamation Clean-Up Pan The Laboratory Clean-Up Pan is similar in design to the commercial machine and is used to amalgamate high grade ore or flotation and table concentrates. It can be operated successfully for batch or continuous work. The unit is mounted on a stand with an adjustable base, so that the charge can […]

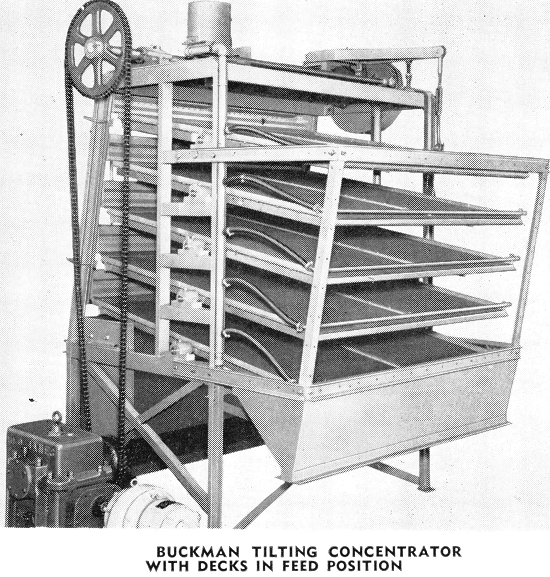

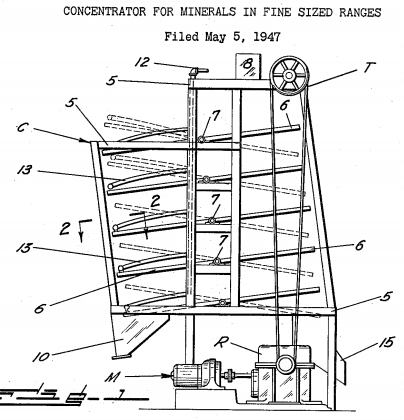

Buckman Tilting Concentrator

The Buckman Tilting Concentrator is a development of the engineering staff of the Consolidated Mining and Smelting Co. of Canada, Ltd. It is named after Mr. R. S. Buckman, the mechanical superintendent at the Sullivan Concentrator. Over one million tons of material were handled by these machines before being offered as a tried and proved […]

Tin Ore Extraction

The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit. Cassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are necessary to avoid an excessive production of fines. The Mineral Jig is an important feature of […]

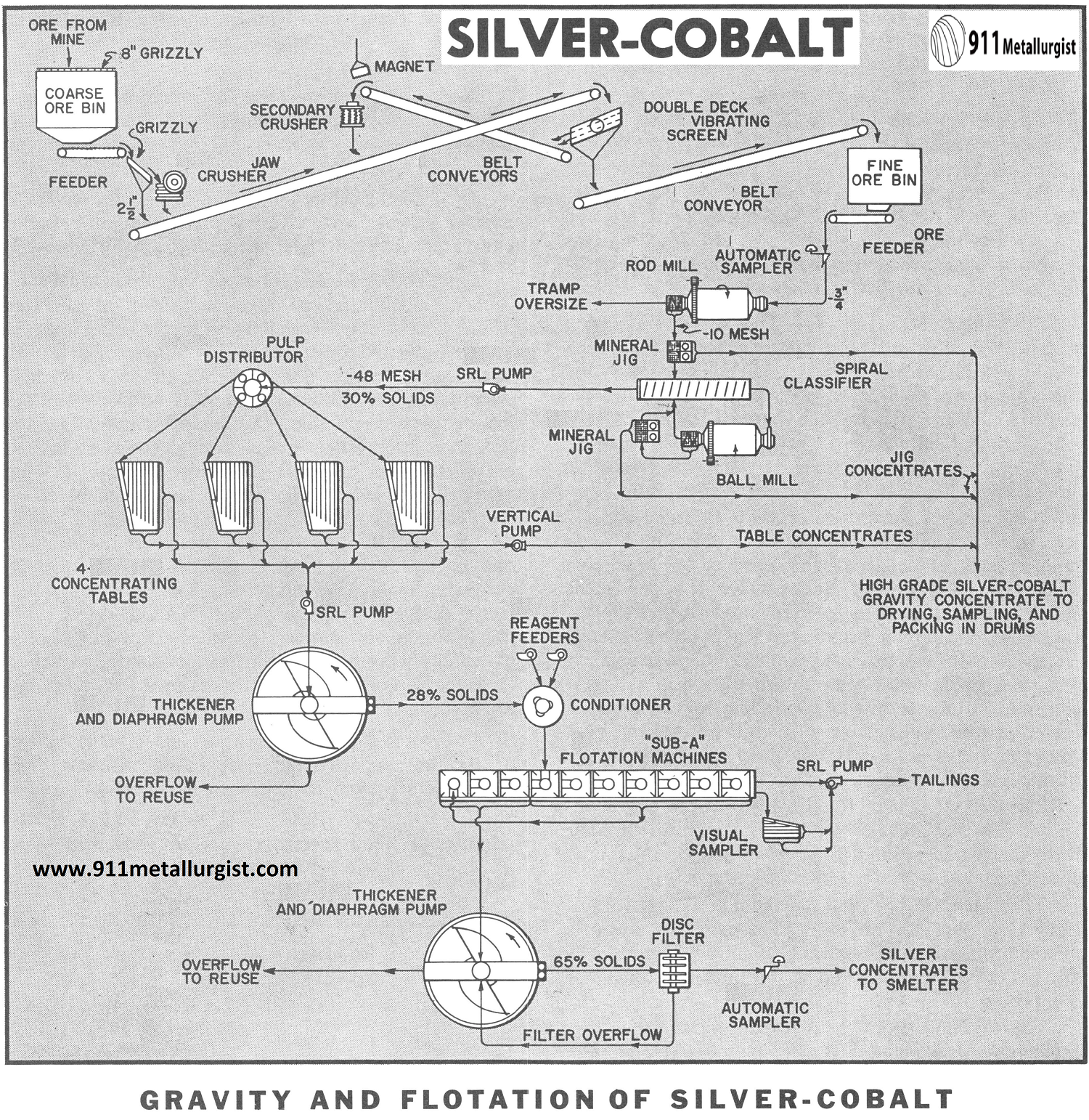

Silver & Cobalt Processing by Gravity and Flotation

The treatment of complex silver cobalt ores occurring with antimony and arsenic require special metallurgical processing to produce concentrates most advantageous for smelting. Gravity concentration is used to initially recover a high percentage of the native silver and cobalt. The concentrate is marketed and payment received for these constituents. Flotation treatment of the gravity tailing […]

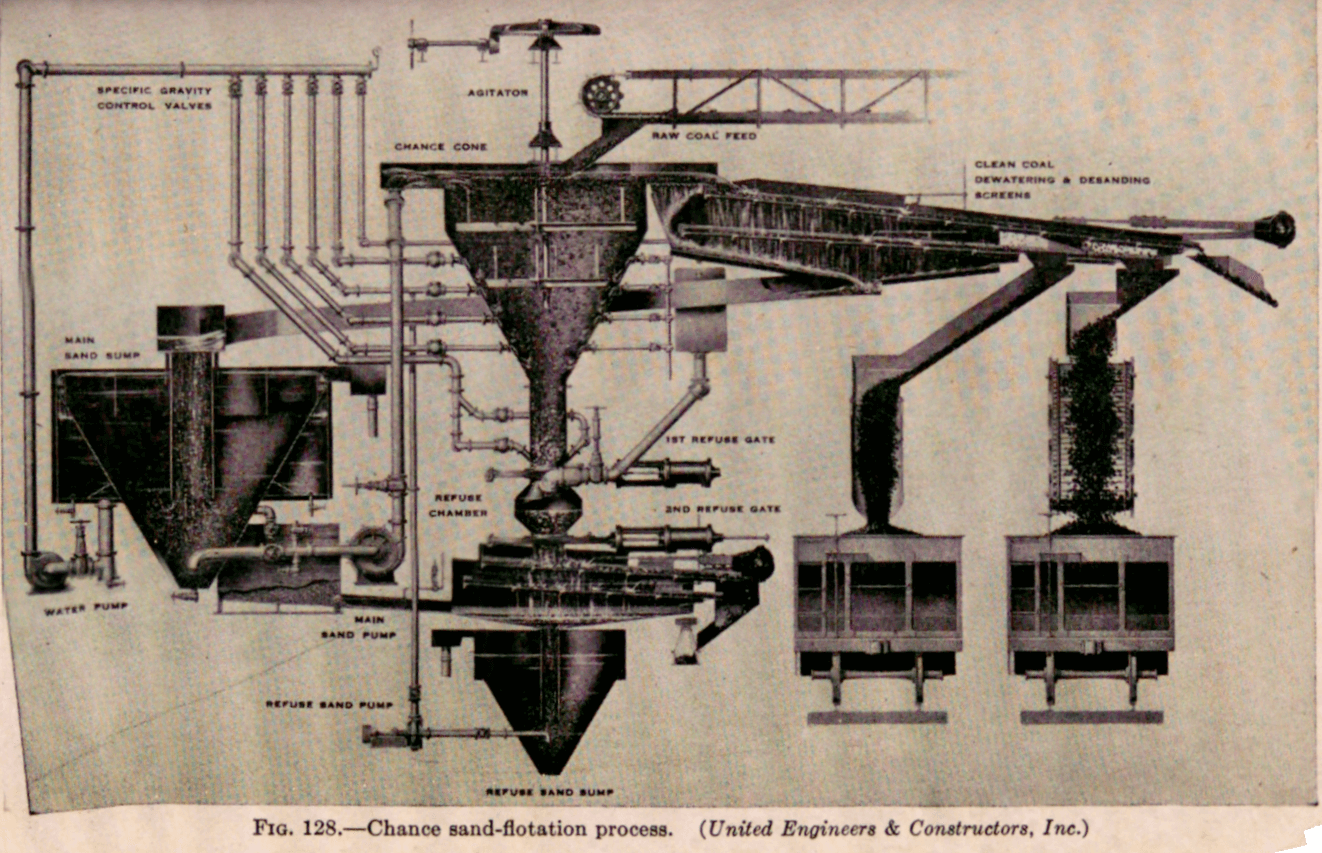

Heavy Media Separation Process

The Sink and Float separation process is part of what is also known as a Heavy Media Separation Process (HMS) and are commercial adaptations of the common laboratory procedure used for separating a mixture of two products having differentials in specific gravity by immersing the sample in a heavy liquid having a gravity intermediate to those of […]

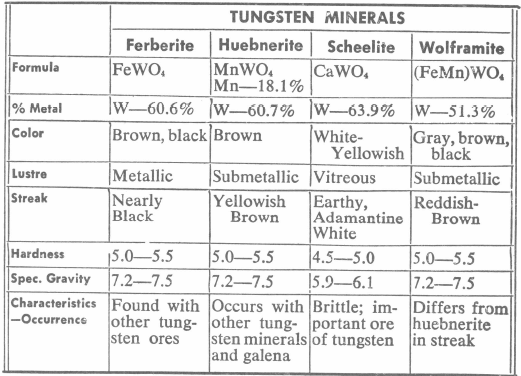

Tungsten Metallurgy

Nearly all alloy steels containing tungsten are made in the electric furnace where tungsten is introduced to the steel’s metallurgy in the form of ferro-tungsten. Ferro-tungsten, melts between 3500 and 3700 degrees F., while tungsten powder melts between 6000 and 6200 degrees F. Neither will actually melt in a steel-making furnace, but the ferro-alloy because […]

Extracting Tungsten from Wolframite Gold Ore

The present great demand for tungsten due to world conditions has resulted in an increase of tungsten ore dressing problems for our metallurgists. The flowsheet study shown here was recently developed for treatment of a very complex tungsten-gold ore. The flowsheet study previously shown for tungsten was devised for a simple tungsten ore free of […]

Extraction of Tungsten from Scheelite Ore

High price and ready market for acceptable tungsten concentrates present a very attractive incentive for the mining and processing of tungsten ores. Since all tungsten ores are very friable and slime easily, concentration must take place as soon as the mineral has been liberated by either crushing or grinding methods. Regardless of the care taken […]

Titanium Ore Processing and Beneficiation

To develop a flowsheet for separation of high grade titanium-rutile from ilmenite, that will meet market requirements. Rutile has a SG of 4.2, hardness 6.0 to 6.5 and is non-magnetic; while ilmenite has a SG of 4.5 to 5.0, hardness of 5.0 to 6.0, and is weakly magnetic. Both minerals are amenable to gravity concentration. Titanium, “the […]

Gold Leaching Equipment, Circuits & Process Plants

In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mine. The small mine of today may develop into the large mine of tomorrow. Under proper management and financing it has as good a chance of yielding a profit as the larger property. Unfortunately large capital is […]