DryWashers Gold Mining

In arid districts where water is scarce or expensive and a “dry” plant is proposed for the recovery of placer gold, a small dry washer may be the logical choice for processing samples. A number of small, hand-powered machines are on the market and most work quite well within certain limits common to all dry […]

Gold Panning Technique

Panning for gold is a simple operation but, at the same time, it is difficult to describe. Although the subtle techniques of gold panning vary with the individual and with the material being washed, the overall gold panning operation can be divided into six basic steps as follows: How to Prepare for Panning After filing the […]

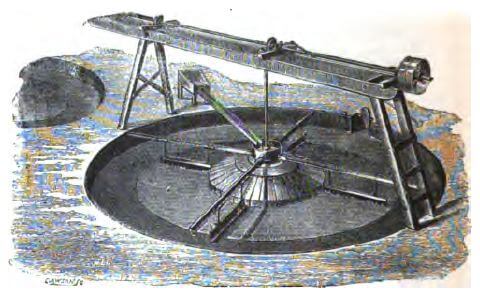

Round Buddle

The Round Buddle was invented in Cornwall, where it is still used in dressing the tin ores to the exclusion of almost every other concentrator. There are two varieties. The convex round buddle, in which the ore and water are added at the centre of the machine, and flow down over the surface to the […]

Gold Gravity Concentration

The object of gravity concentration is the separation of the heavy valuable mineral from the light worthless gangue. Complications are often introduced by the fact that various base minerals must be separated from one another, an ore being subdivided into several products. Most gold ores, however, only require separation into two parts—the “concentrates,” in which […]

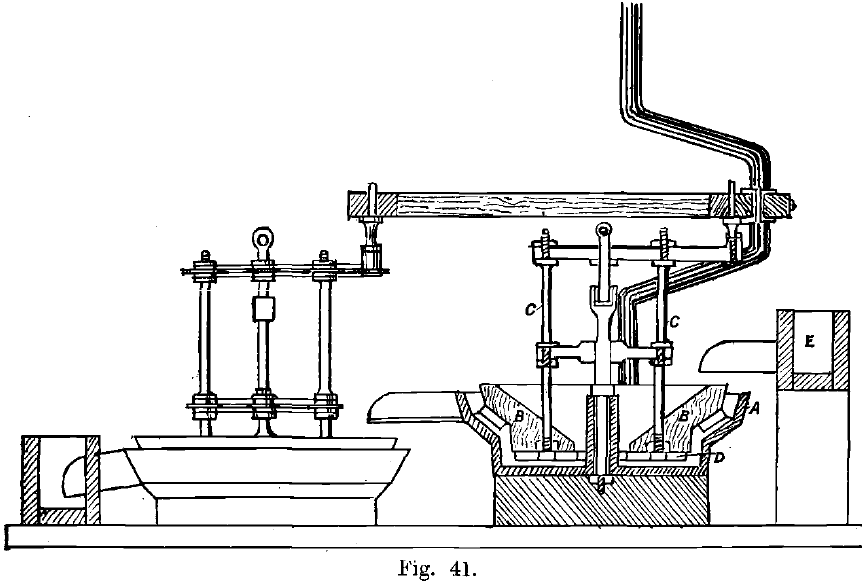

Concentrating Gold with Oil

It has been found that in the case of certain ores, residuum oil separates sulphides and metallic particles from earthy or stony materials without reference to their respective densities. In the Elmore concentrating process, which was introduced at Glasdir, near Dolgelley, in Wales, the ore is crushed in Huntington Mills, and the pulp mixed with oil […]

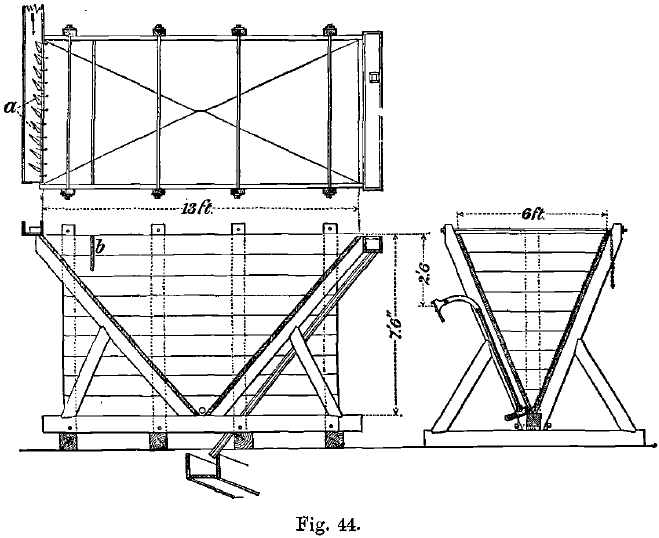

Gold Settling Box

Gold Settling Boxes are of the same shape as the spitzkasten or pointed boxes introduced by von Rittinger. They are for the purpose of allowing the sand and mineral in suspension in a flowing current to settle, so that the part of the water not needed in the subsequent treatment of the ore may be run […]

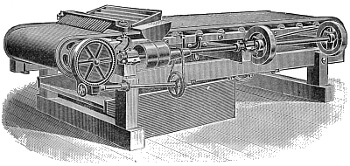

Frue Vanner

The Frue Vanner is described in detail as being typical of the shaking travelling-belt concentrators. Machines of this class are especially adapted for treating finely-crushed battery sands which do not contain a large percentage of “mineral” (that is, sulphides and other heavy materials). They are frequently set to concentrate unsized pulp coming straight from the amalgamating tables. The […]

Roller Mills

In the Griffin Mill, there is a single roller suspended in a similar way to the rollers in a Huntington mill. The roller is about 18 inches in diameter, and rolls on the inside of a die ring 30 inches in diameter. It takes material up to 1½ inches in diameter, and crushes either wet […]

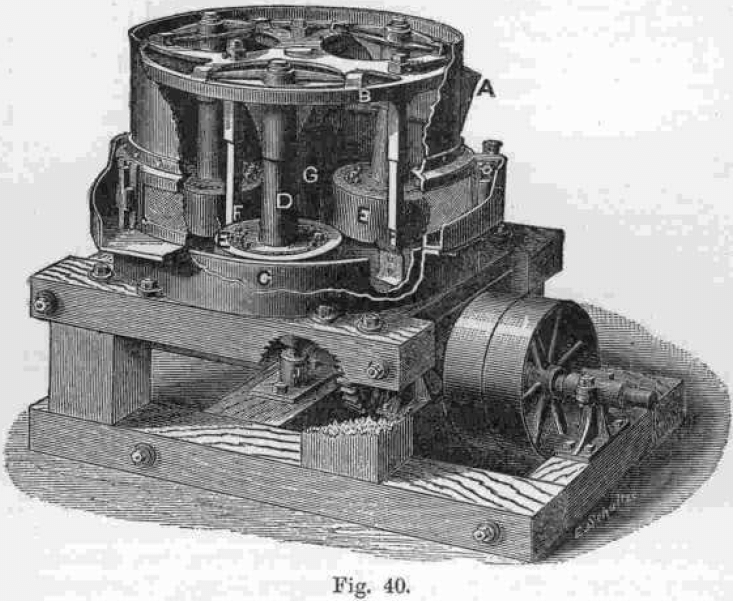

Huntington Mill

The Huntington Roller Mill, here described as a type of the many good roller mills now in use, is best suited for the fine crushing of ores which are not too hard. It consists of an iron pan, at the top of which a ring, B (Fig. 40), is set, and attached to this are three […]

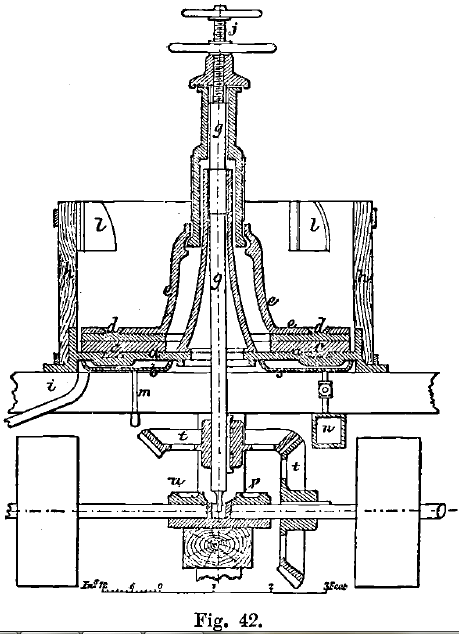

Amalgamation Pans

An amalgamation pan consists of a circular cast-iron pan, provided on the inside with a renewable false bottom of cast-iron—constituting the lower grinding surface—and a “muller,” of upper grinding surface (d, Fig. 42), attached to a vertical revolving spindle, g, which is set in motion by bevel wheels, t, placed below the pan. The muller […]