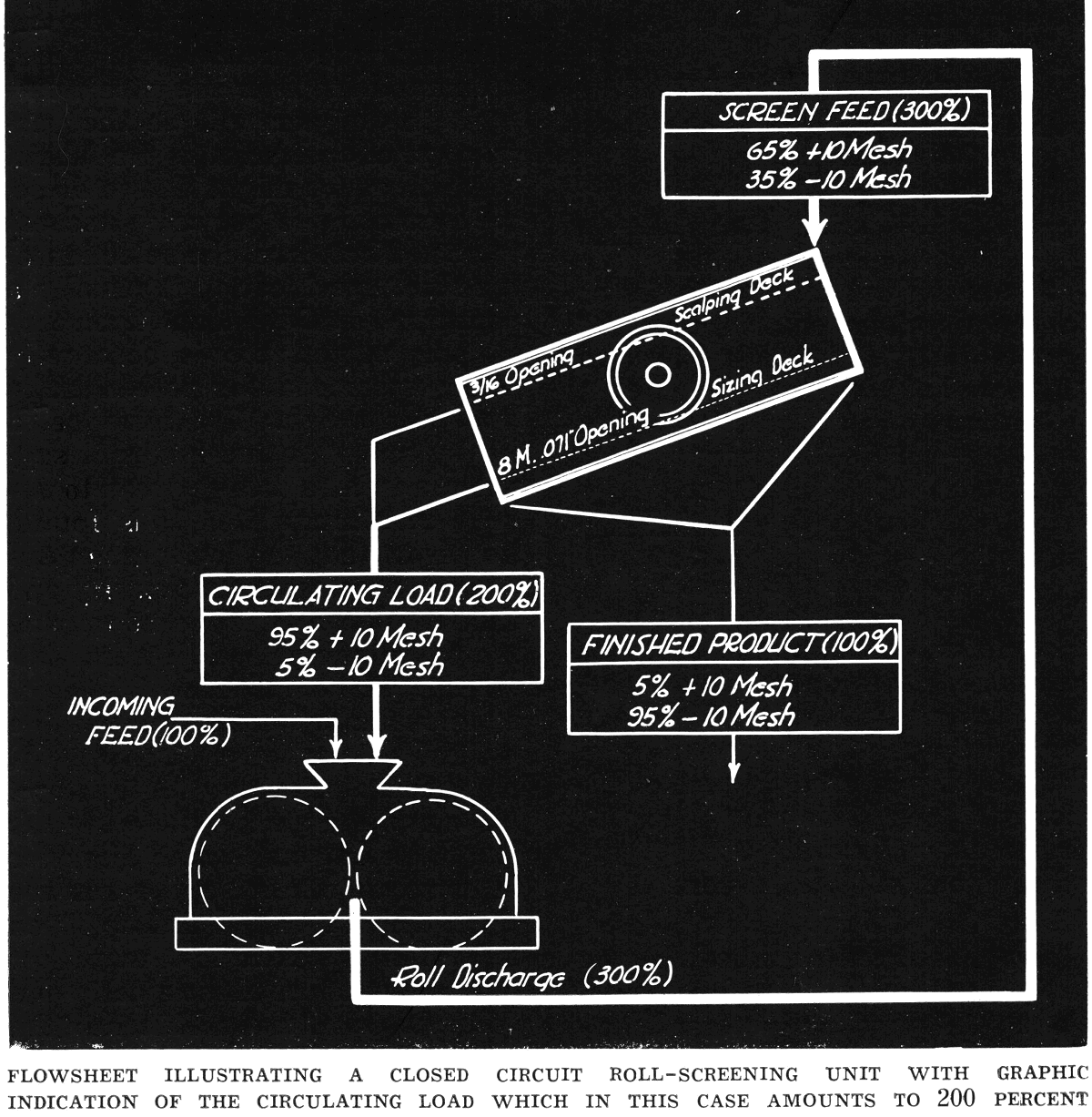

Screening 101

Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of […]

Mineral Processing Pilot Plant Equipment

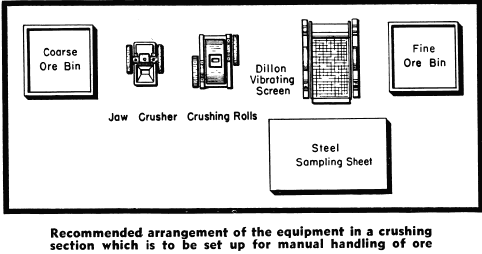

The testing of tonnage lots of ores and industrial materials by continuous Mineral Processing Pilot Plant operation is in many instances advisable before a full scale milling plant is installed. The treatment of complex ores by new processes or by the use of new or unusual reagents in flotation may involve problems the effect of […]

Metallurgical Laboratory Equipment & Test Methods

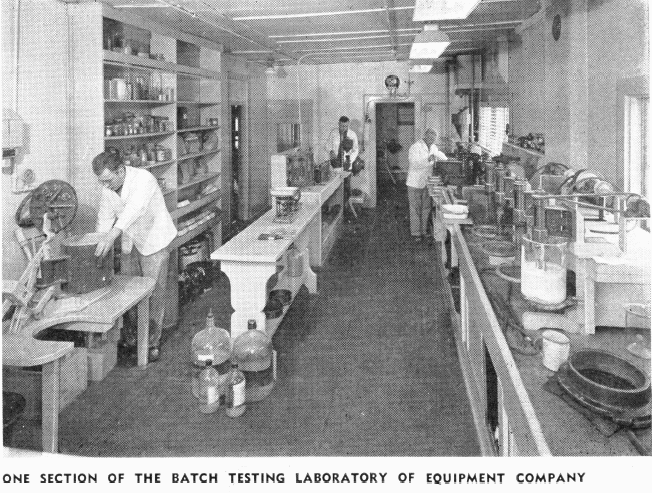

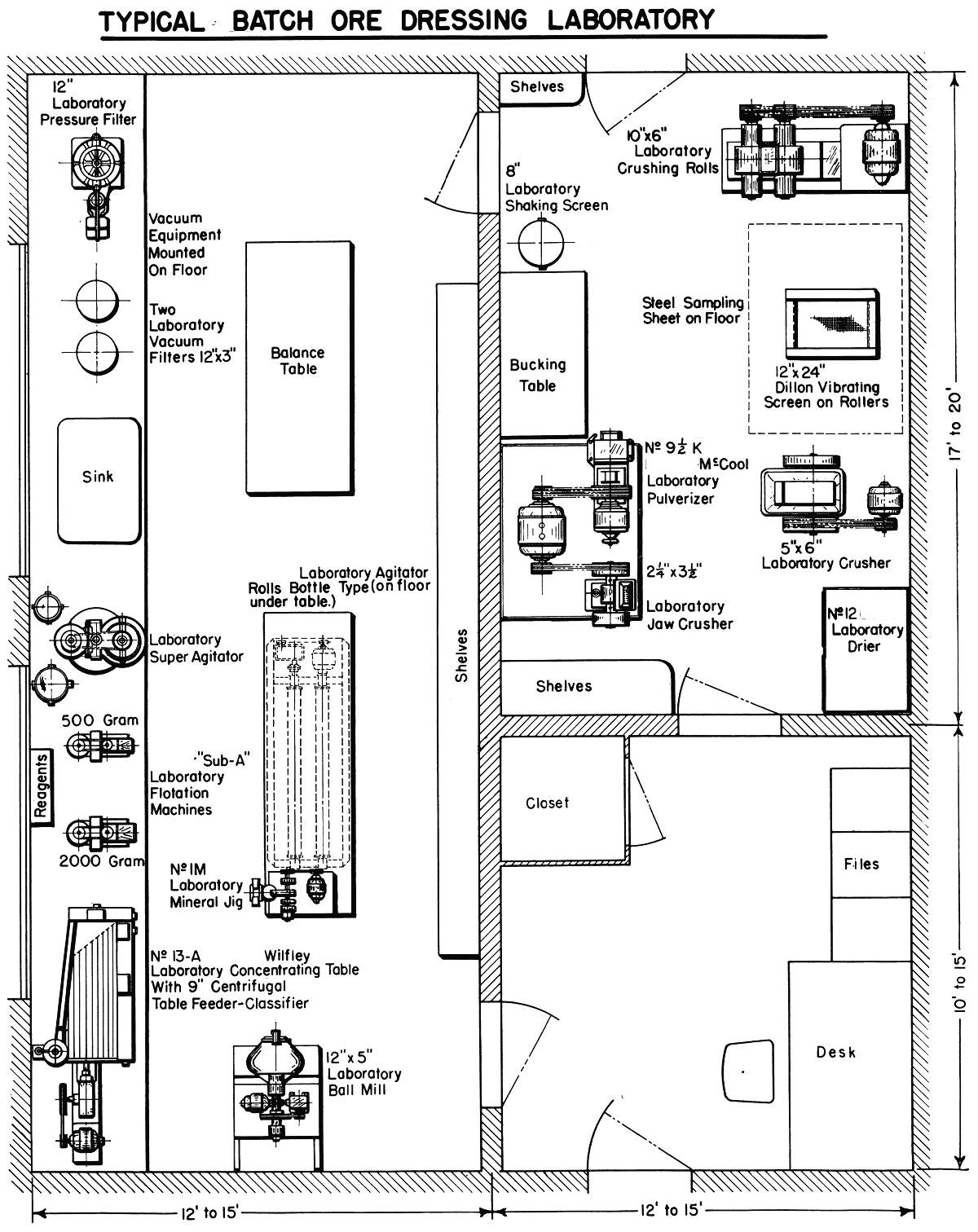

The Mineral Industries have for many years recognized the importance of small-scale ore dressing tests for determining the amenability of ores to various methods of concentration. The successful development of the flotation process, which was accomplished with the aid of small-scale laboratory machines, gave a decided impetus to the laboratory testing of ores. Today the […]

Metallurgical Laboratory Design

Size by Size Particle Size and Flotation Recovery

The unseen factors in flotation are those which affect the economic recovery and are not shown by the assays or analyses. The fact that equal tailings and equal grade of concentrates can be produced with widely varying physical properties of the products recovered and rejected is unrecognised in most cases. In the past, when studying […]

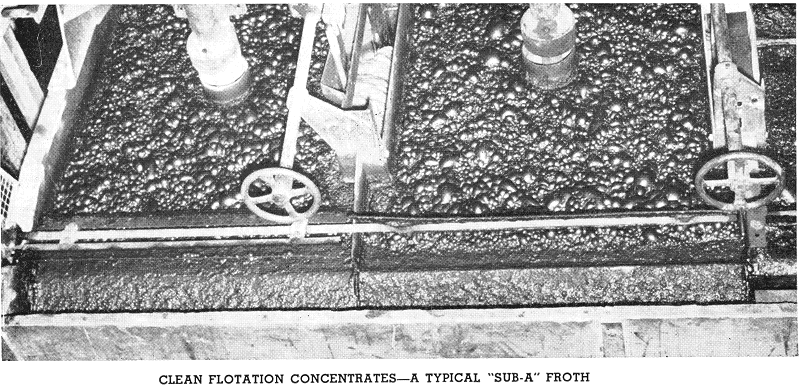

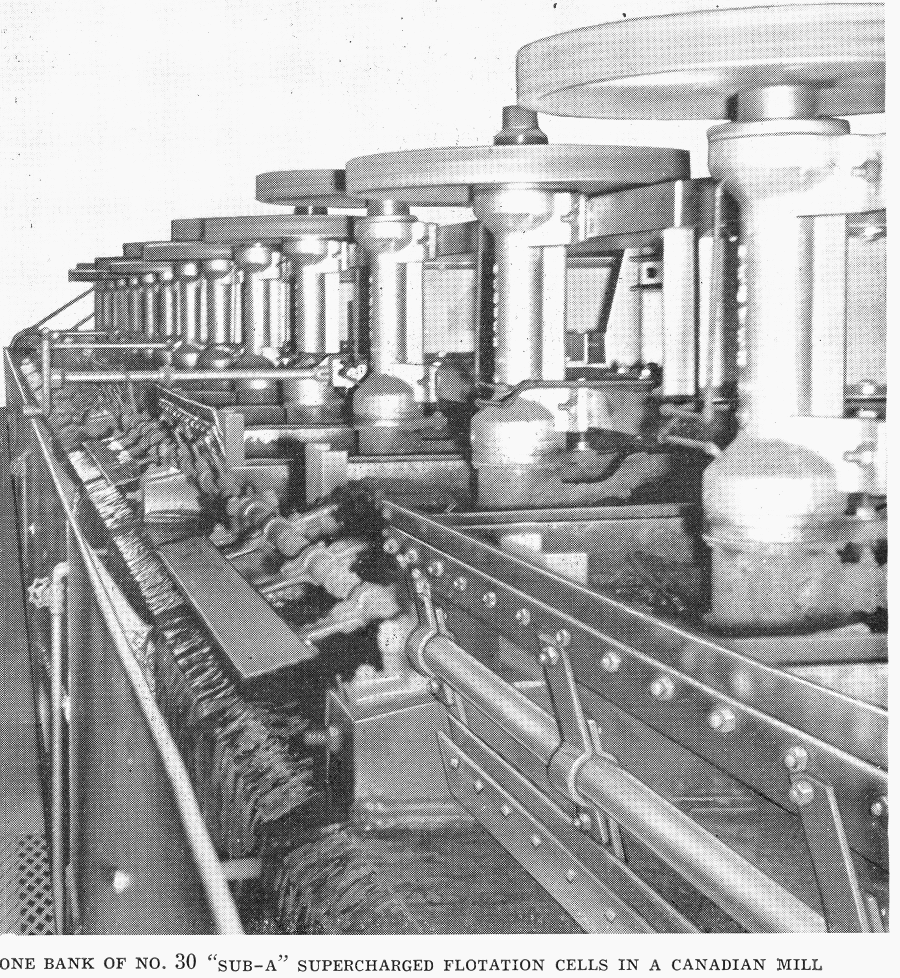

Froth Flotation Machines

There are certain variable factors which affect the Fundamental efficiency of a Flotation Machine. These factors, having different degrees of importance, are as follows: Type of Froth Flotation Machine Mesh analysis of the pulp Density of the pulp Reagents and pH Pulp temperature Conditioning Circulating load Contact period Aeration Of these factors influencing the flotation process, each […]

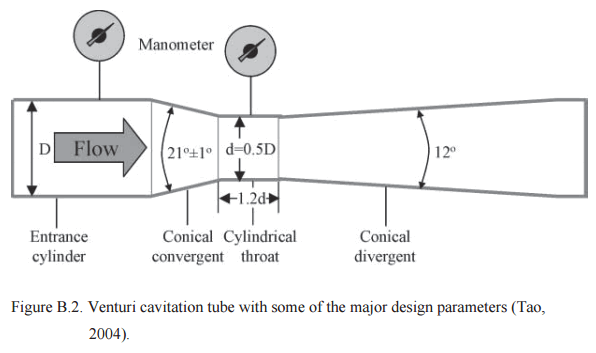

Venturi Cavitation Tube

Three types of convergent sections exist in classical Venturi tubes, i.e., machined, roughcast and rough-welded. Each type specifies a set of ranges for the entrance diameter (D), the diameter (Beta) ratio (β=d/D) and the Reynolds Number (ReD). The Venturi design in this study was specified to have a smooth (machined) internal surface in the convergent section, which is especially […]

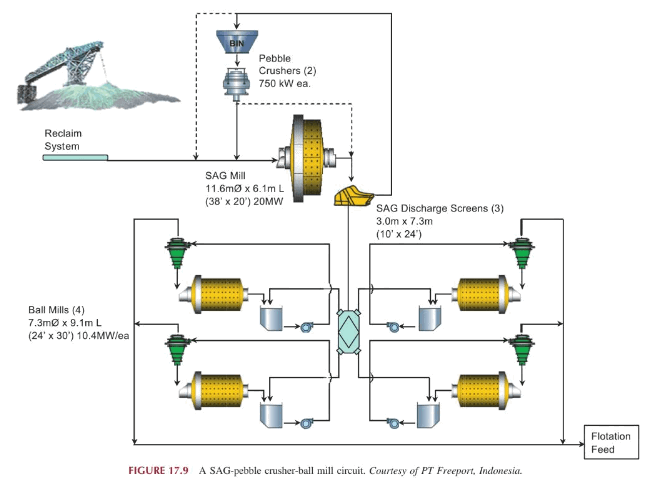

SAG Mill Grinding Circuit Design

AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations. SAG circuits are common in the industry based on: High single-line capacities (leading to capital efficiency) The ability to mill a broad range of ore types in various […]

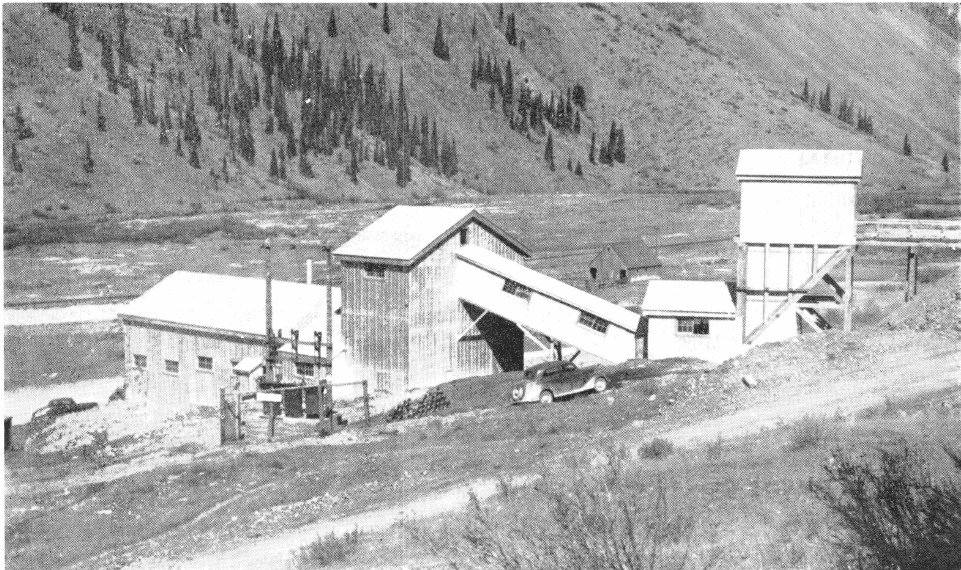

Mineral Processing Plant Design & Construction Example

Metallurgical Recovery, which consists of the percentage of mineral saved, must not be confused with economic recovery which covers the percentage of the gross value of an ore recovered as a net profit. In other words, in commercial practice the prime object is the highest possible net profit over and above all costs. Thus a […]

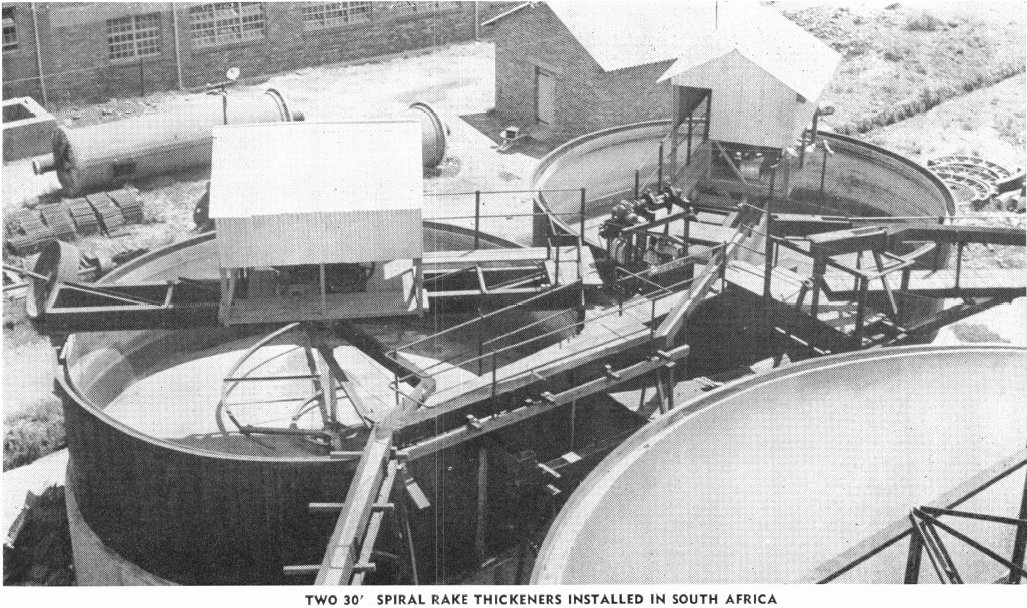

Thickeners

The practice of thickening or clarification is usually carried out in decantation tanks employing gravity settling or sedimentation. These tanks are fitted with mechanical scrapers to collect and move the settled solids to the point of discharge, the clear overflow being collected and removed by means of peripheral launders. These tanks, equipped with mechanical scraping […]