Laboratory Flotation Equipment & Testing

The apparatus listed in the following pages comprises the equipment necessary for complete and thorough testing of flotation processes. Some of it can be omitted where the problems to be studied are of a special character. It is urged, however, that such omission be of the actual flotation machines themselves rather than in the apparatus listed for preliminary […]

Liebherr Hydraulic Excavator Parts

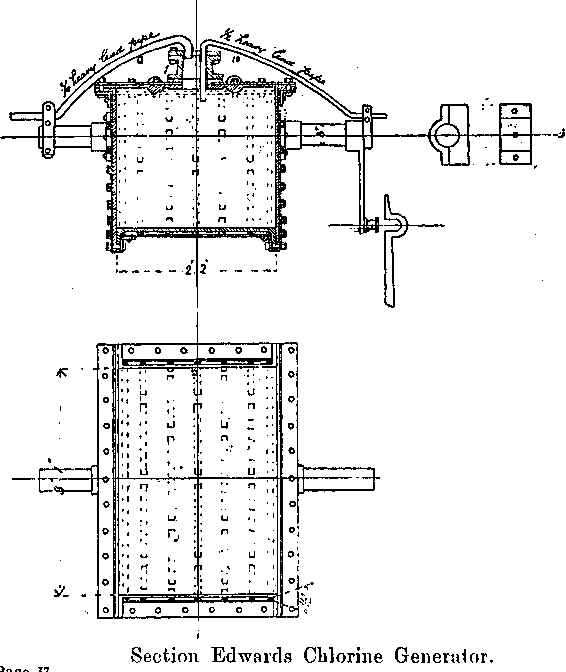

Miller Gold Refining Process by Chlorination

The term refining has been very often applied to the removal of base metals from the noble ones, or, in other words, separating the oxidizable from the non-oxidizable ones. When used in this sense it is generally applied to the term bullion, which is an alloy carrying gold and silver, the bullion being pure when […]

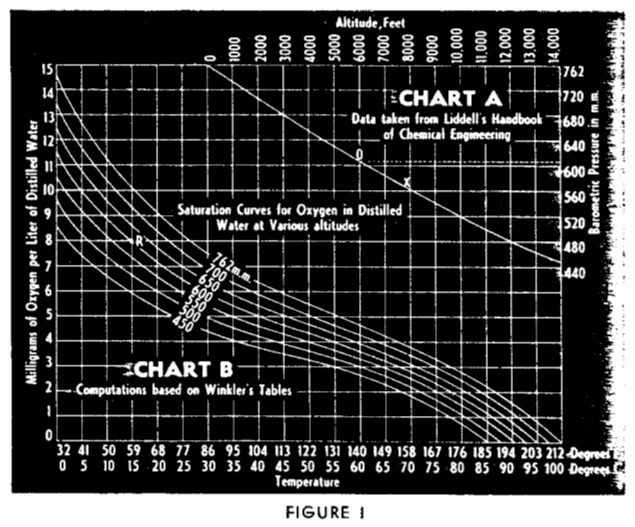

How to Operate a Merrill Crowe Precipitation Process

Efficient Merrill Crowe precipitation of gold and silver is dependent upon the proper control of certain physical and chemical properties of the solution. The most important of these properties are listed below: SUSPENDED SOLIDS, such as ore slime and precipitates of calcium carbonate, with hydrates of aluminum, magnesium and iron, present in the pregnant solution […]

Merrill Crowe Process & Equipment

Here is described the essential features of the Merrill Crowe Process and its equipment/apparatus used for the Simultaneous Clarification, De-aeration and Precipitation of cyanide solutions. Limited space has prevented a full description of all of the details involved but we have pointed out the application of the various types of equipment and the advantages to be […]

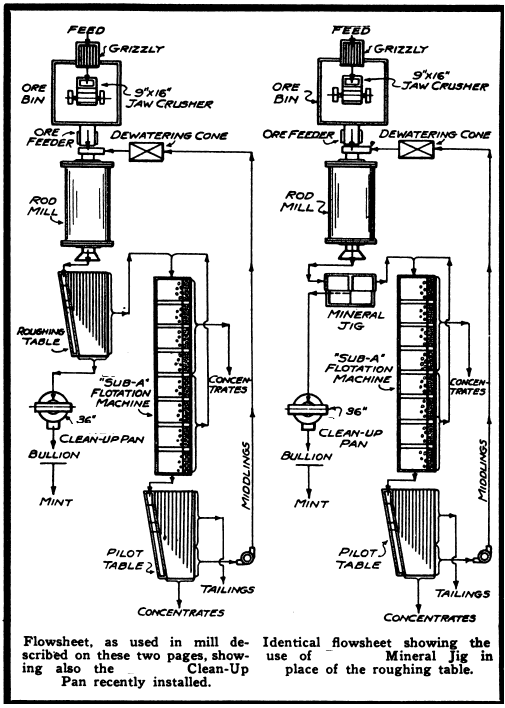

Operating Costs of Gold Processing Plant

A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be ‘obtained when handling a low grade ore by a simple process. There are many commendable features in such a set up and no complicated machines or practices are embodied in this plan. In fact, its […]

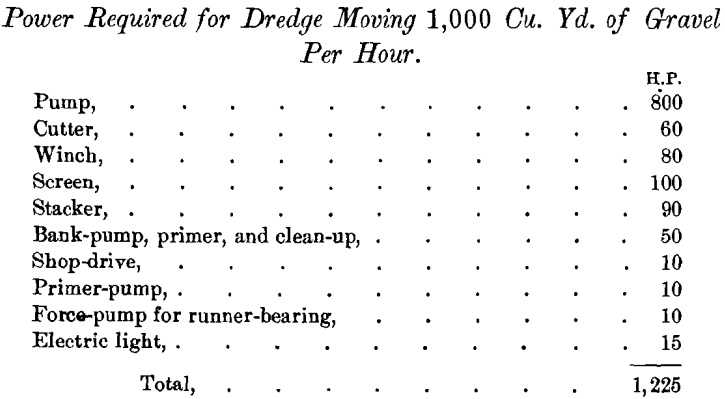

Hydraulic Dredging for Gold-Bearing Gravels

Repeated failures in attempts to work gold-bearing gravels by means of suction-dredges have created the impression that this method is impracticable. The suction-dredges have failed from three special causes: excessive wear and frequent breakage of pump-shell, runners and liners; inability to dredge compact gravel which would not readily move towards the intake; and, most important […]

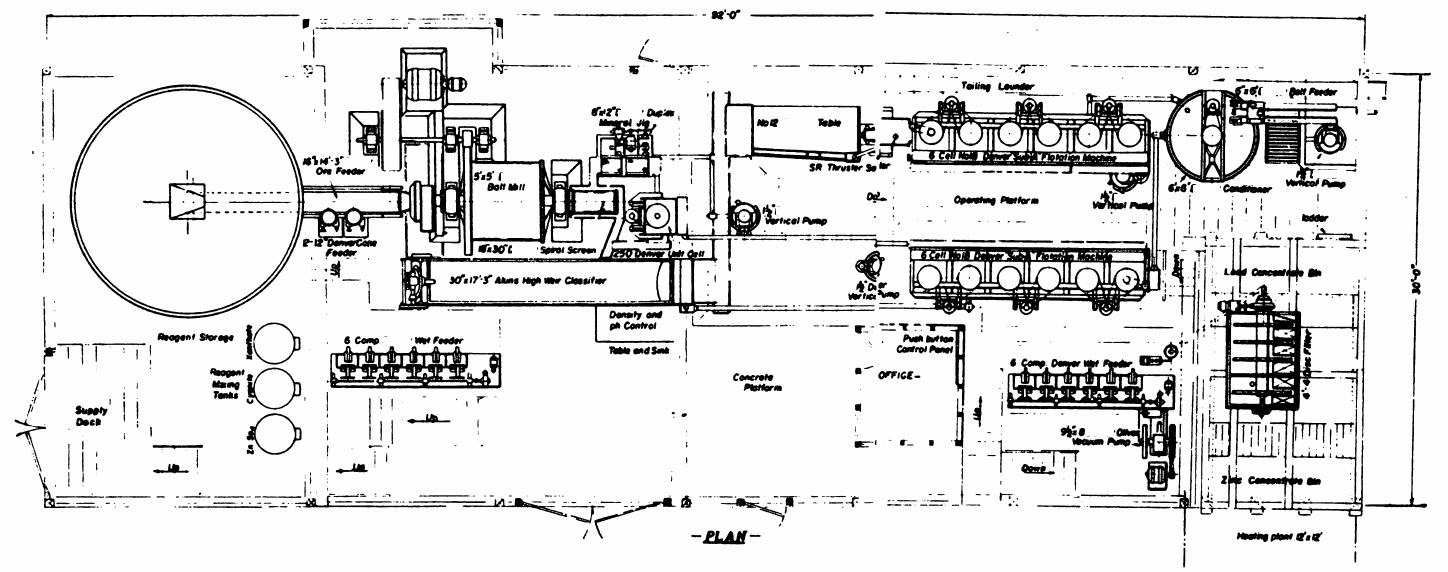

Small Mineral Processing Plant Design / Construction

Small mines are almost invariably adit rather than shaft mines, and in most instances ore is trammed directly from mine to coarse ore bin at the mill for crushing. Accordingly, most mills are situated adjacent to the portal of the main haulage level. In a few cases, location of the mill at the mine is impractical […]

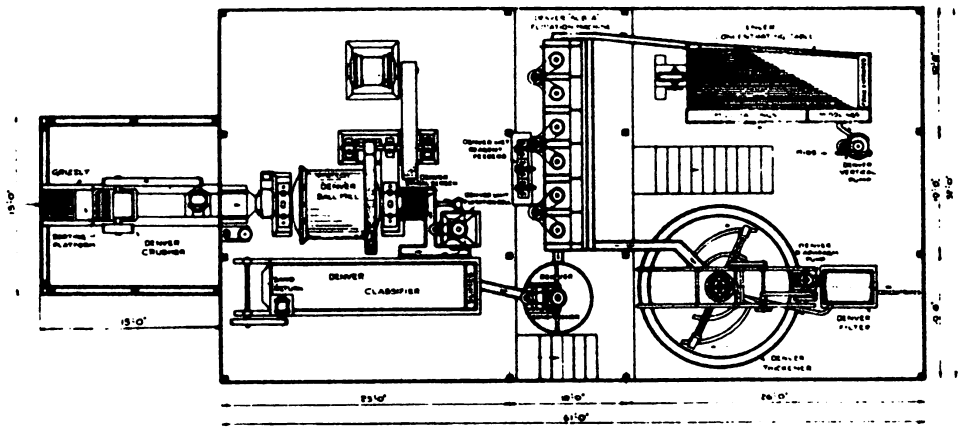

Mobile Ore Processing & Beneficiation Plant

One of the most serious problems confronting the mining industry today is how to profitably begin the small scale milling of ores from mines where insufficient ore has been developed to warrant an expensive mill installation, but where a large plant might be needed later. The same question arises in connection with the economical working […]

100 to 125 TPD Process Plant Design & Equipment

The 100 to 125 Ton/Day Mill is arranged along the same standard lines as the smaller mills, and a large oversize forced feed crusher is recommended for primary crushing. An intermediate crusher can be installed later if necessary. Changes can be easily made according to your local conditions. Here too, a Selective Mineral Jig may be […]