Treatment Methods for Mining and Ore Processing Wastewaters

Increased emphasis on industrial pollution control has intensified investigation of waste treatment technology for methods of reducing the amount of pollutants discharged by industry. The mining and mineral processing industry can point to a record of considerable accomplishment in the field of wastewater treatment and reclamation because these operations are so frequently an integral part […]

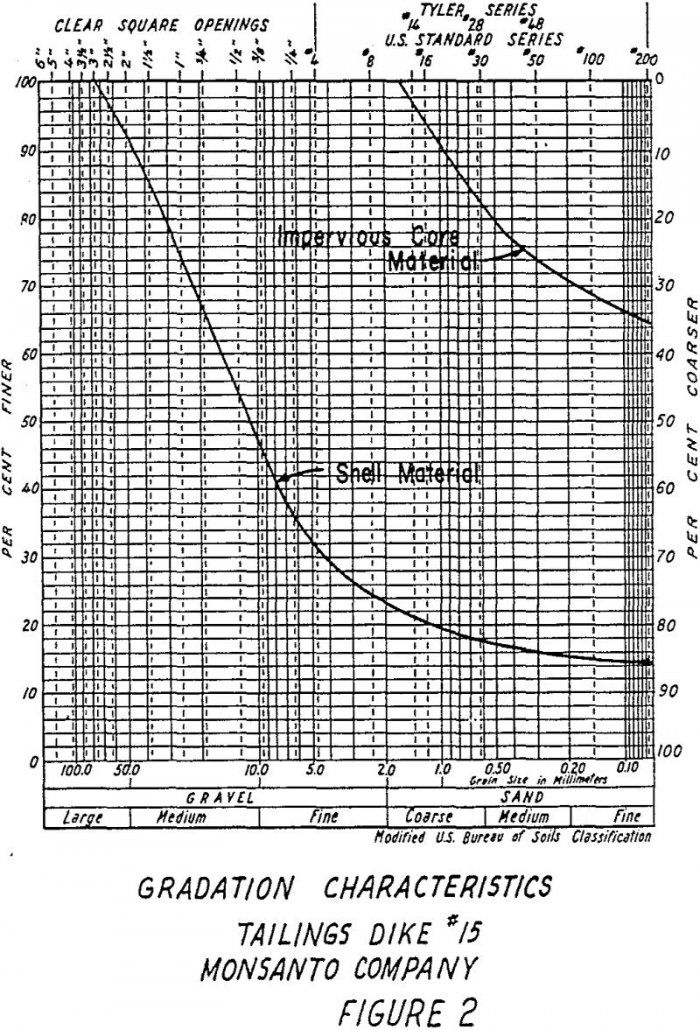

Tailings Dam Sealed by Slimes Slurry

In 1965, Monsanto started planning of a new dike (No. 15) for use in disposing of ore tailings at its Columbia, Tennessee phosphorus plant. Generally, in the phosphorus industry only clay tailings are produced making it necessary to borrow fill for construction of a retaining dike. Borrow area investigations indicated that weathered shales and limestones […]

Gypsum Tailings Pond Design

Tailings disposal has been a problem for the mining engineer since the beginning of the metal milling process. Disposal systems in common use have evolved as the most economic method for the disposal of an unwanted waste material within the disposal restrictions in force at the time of construction. As restrictions are constantly being expanded, […]

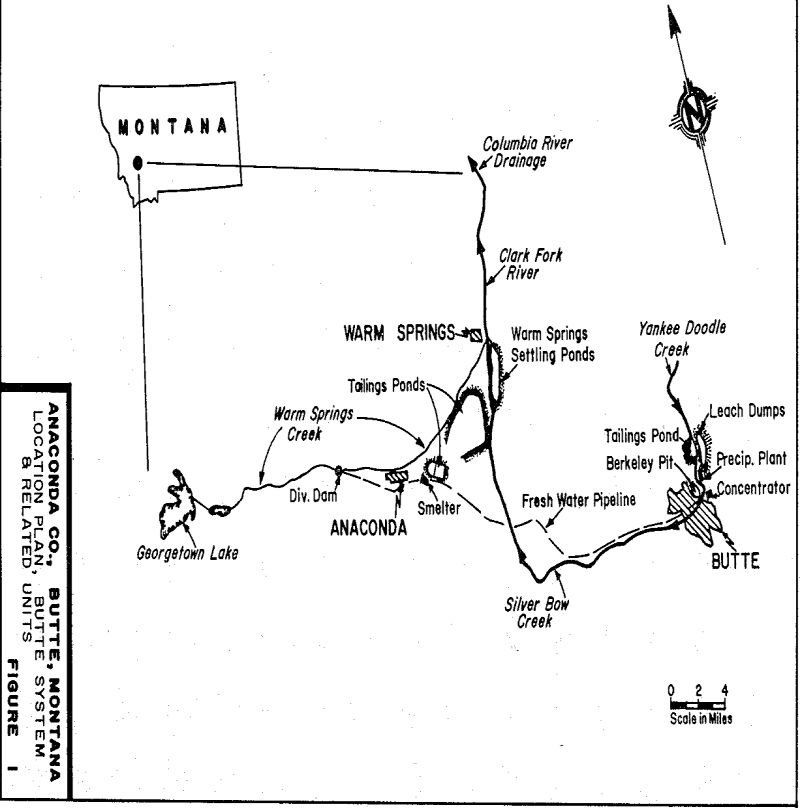

Chemical – Quality Control of Metallurgical Wastes

There are generally four operational units in Butte: underground mines, open pit mine, concentrator and precipitation plant. As with copper production, the waste water systems for all units are interrelated. Acidic mine water is pumped up the Kelley shaft and distributed on leach dumps. Major waste water discharges from the Butte operations include: about 4400 gallons […]

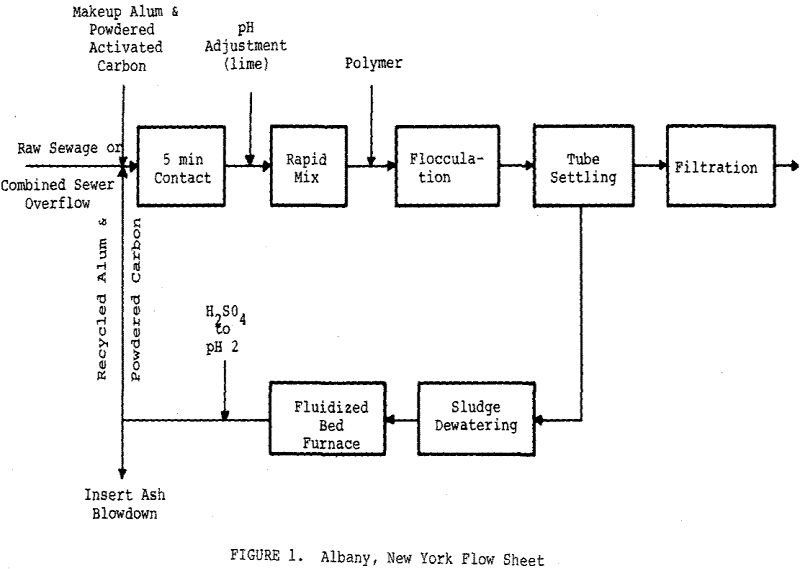

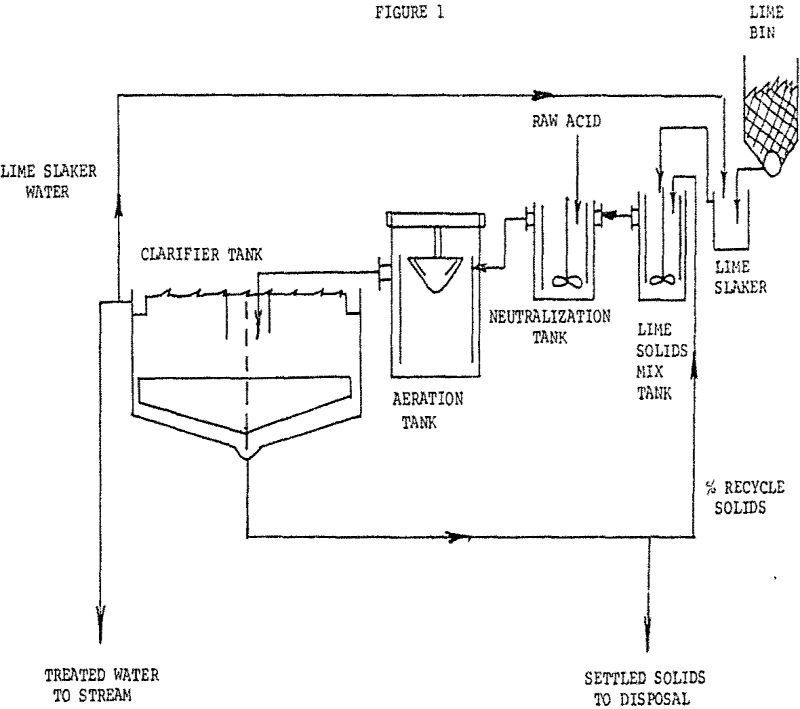

Advantage of a Crowd for Acid Waste Liquors

Because of increased pressure from Federal & State Regulatory-Agencies, most acid flows will require some sort of treatment prior to being discharged to receiving streams. In many industries, the volumes of liquors are large and their acid content varied. “Standard” methods of acid neutralization with lime have been known for years, however, the volume and […]

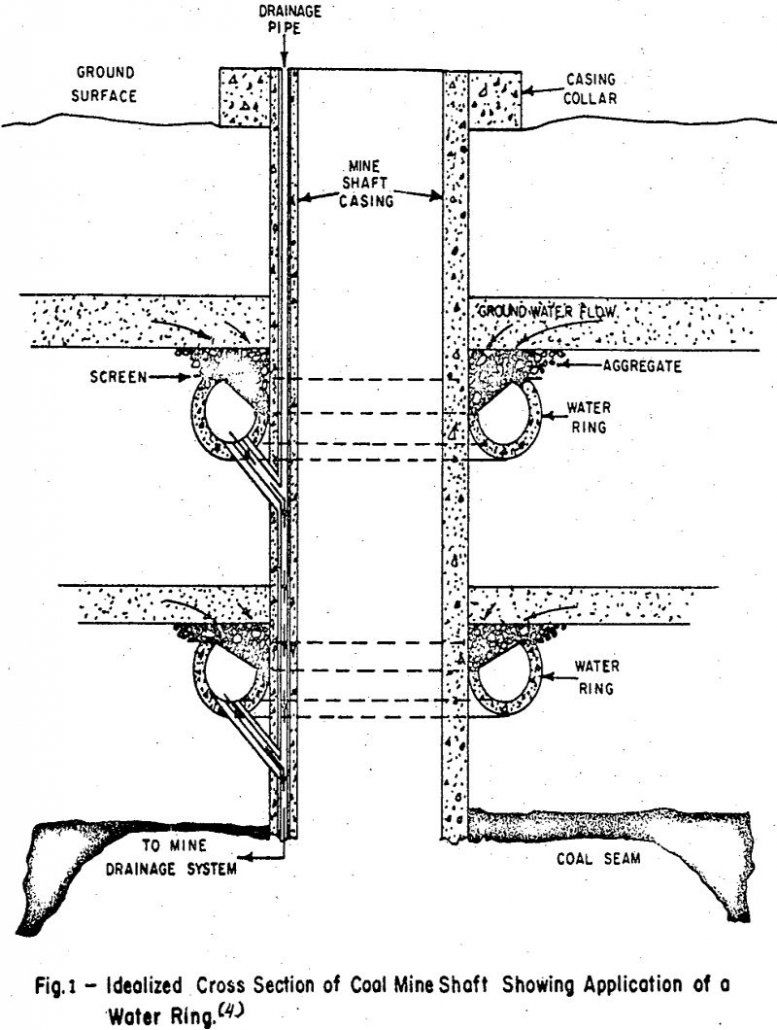

Acid Mine Drainage Control Methods

In past years, water drainage control in coal mines has been primarily directed on the basis of water quantity rather than quality. Due to the recent intense interest in total ecology and environment, emphasis has shifted to the point where the water exiting from a mining operation may be of better quality than when it […]

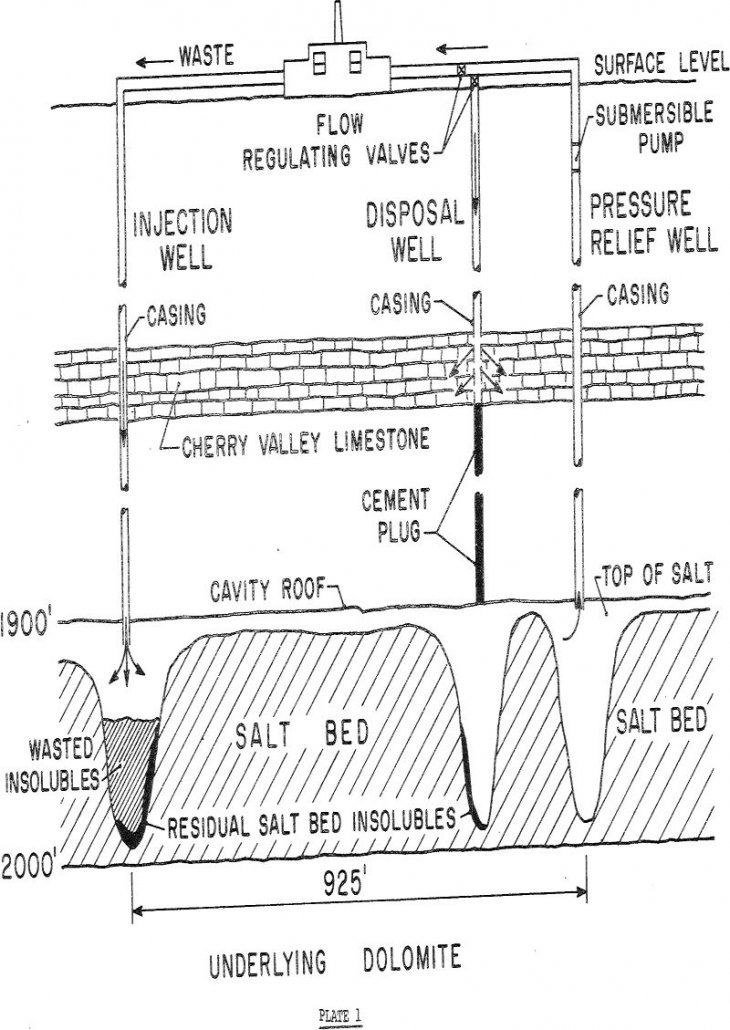

Underground Storage of Mine Wastes

In 1960 the management of International Salt Company made the decision that all waste material from the Watkins Glen plant would be stored in underground salt cavities. The cavities which they contemplated using had been depleted of salt to a point where continued operation would have impaired their structural stability. Originally, the waste to be […]

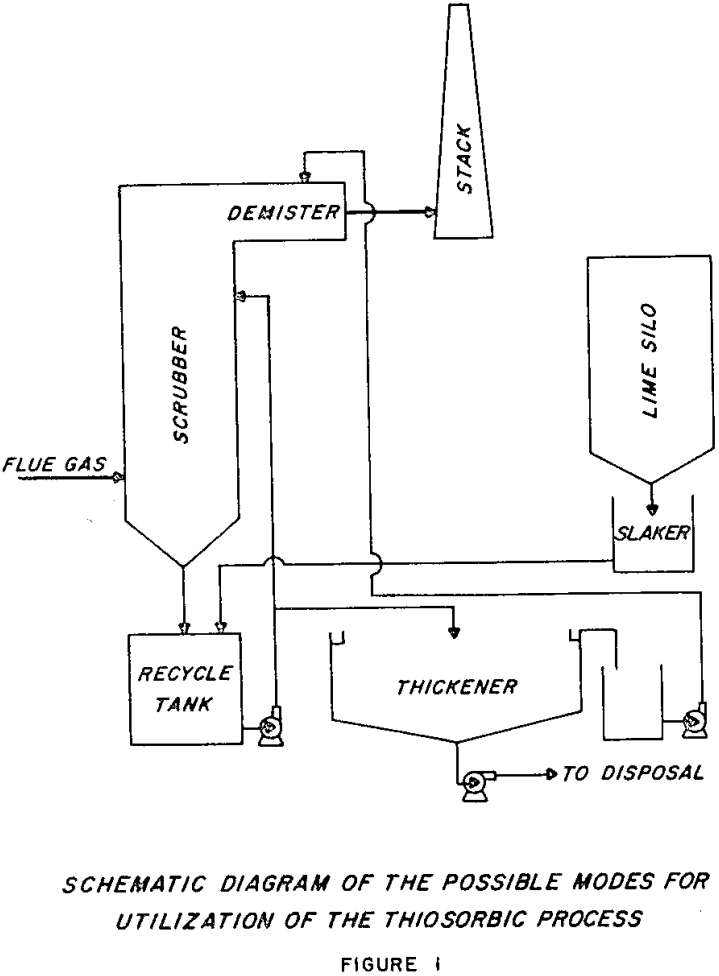

Thiosorbic SO2 Scrubbing Process

Lime and limestone-based SO2 scrubbing processes have demonstrated reasonably good success in removing low concentrations of SO2 from flue gases. While most of the operating problems experienced in the early days of scrubbing have been worked out, problems usually increase and removal efficiency drops with increased amounts of SO2 present in the gas stream. Thiosorbic […]

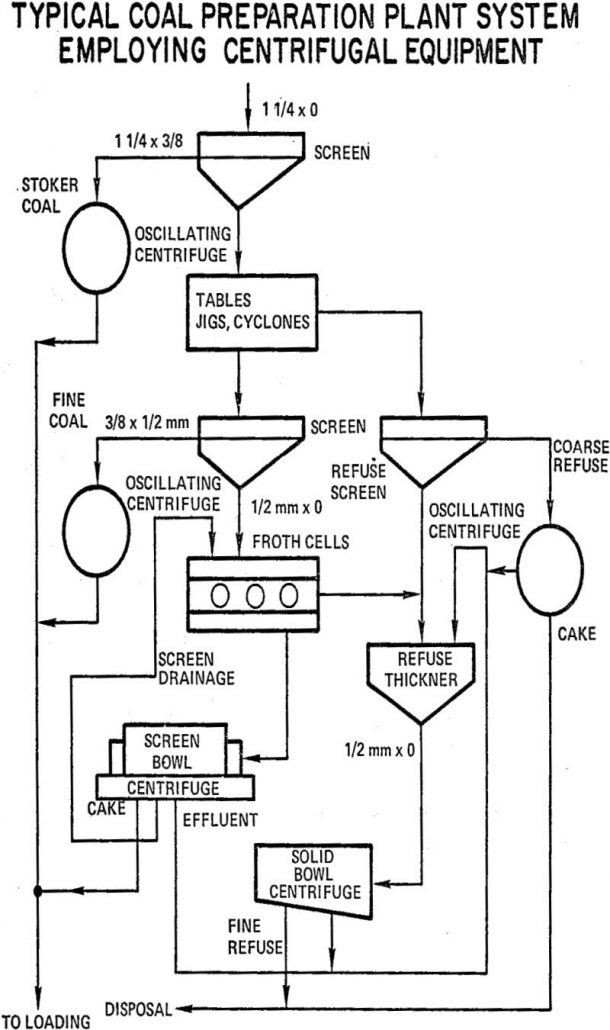

Pollution Reduction and Product Recovery by Centrifugal Dewatering

The requirements for controlling air and stream pollution are a most timely subject for all concerned people. The coal industry has taken great measures to reduce both types of pollution. To help eliminate stream pollution and the hazards created by tailing ponds, the coal industry is using centrifugal dewatering equipment. Use of centrifugals to dewater […]

Storage of Sulphide Bearing Tailings

The problem is typified in the tailings of the uranium operations of Elliot Lake, Ontario, where mining started some 20 years ago. The approach to tailings disposal paralleled the practice for other hydrometallurgical plants treating gold and base metal ores. Impoundment areas were designed to retain solids, and a clear and neutral overflow was considered […]