Table of Contents

Congress, by the Solid Waste Disposal Act of 1965, delegated to the Bureau of Mines responsibility for conducting research on solid waste problems. The accumulation of abandoned automobiles is one of these problems, and this paper reports the efforts of the Bureau’s Salt Lake City Metallurgy Research Center in attempting to resolve the abandoned car problem.

Every year about 8 million automobiles are discarded. Of these, about 1 million are added to the 15 million abandoned cars that now litter our countryside. The unsightly rusting hulks blight our environment and represent a waste of a potentially valuable resource of ferrous and nonforrous metals. The blight and waste problem is concentrated in areas distant from major ferrous-scrap-consuming centers. Its origin and growth are attributable to decreased demand for auto scrap, increased processing costs to prepare high-quality scrap, and increased supplies of junk cars.

The other 7 million wrecked and wornout automobiles are processed yearly by auto wrecking and scrap metal firms to recover reusable parts, steel, cast iron, and nonferrous metals. After the cars are stripped of marketable parts-battery, radiator, and cast iron motor block the hulk is further processed by either traditional baling or recently developed shredding methods.

The shredding process uses huge hammer mills which are capable of tearing an automobile, less the engine and gas tank, into fist-size chunks in about 1 minute. The shredded metal is processed magnetically to separate the steel from the nonferrous metals and nonmetallic materials. Shredding features rapid processing of unincinerated cars and production of scrap admirably suited for use in electric furnaces. A shredding plant represents a large capital investment, and low-cost operation is possible only with a constant large supply of automobiles. For this reason, economic operation of shredder plants is usually limited to the Nation’s major urban areas.

The baling method comprises removing tires, battery, radiator, and engine incineration; stripping to remove nonferrous metals; and finally baling to prepare a clean and marketable steel. The bales can also be sheared after baling if smaller size scrap is desired. Compared to a shredder plant, the capital investment and capacity of a baler-type operation are modest. A supply of about 250 cars per week is adequate for a baler plant. Unit operating costs are higher than for a shredder-type plant, and incineration is mandatory. A: open-air burning with resulting air pollution is rapidly being forbidden in most States, baler-type operations are faced with installing smokeless incinerators.

A recent study indicates that removal of combustibles in a smokeless incinerator followed by dismantling is an economically attractive method for producing quality scrap which can be either baled, baled and sheared, or shredded. As incineration is necessary prior to baling and is desirable prior to shredding, a study was initiated of the problem of designing, building, and operating a low-cost, smokeless incinerator of moderate capacity. The incinerator described in this report was designed, built, and operated by the Bureau of Mines in cooperation with the Wasatch Metal & Salvage Co. of Salt Lake City, Utah. Construction of the incinerator was completed in October 1969 and preliminary testing completed to examine and generally define suitable operating conditions, capacity, and costs. While the bulk of the operating research data are yet to be obtained, this report was prepared to provide the many interested firms with information on progress in developing a relatively simple and low-cost automobile incinerator. The exact costs for construction and operation of the incinerator are not yet available, but $22,000 is considered to be a rough construction cost. The incinerator was built of both new and used materials which affected both the design and cost. This must be considered in estimating the capital and operating costs of a similar incinerator built entirely of new materials in another area.

Design and Operation

Several different types of incinerators have been built and operated by the auto scrapping industry during the past 10 years. These have ranged from small pit-type incinerators capable of burning 10 to 15 cars a day to large, conveyorized, kiln-type burning chambers which can burn in excess of 300 cars per day. Car bodies were burned in different positions and conditions using a range of supplementary air, gas, and oil burners. Air pollution control devices tested included oil and gas afterburners, electronic precipitators, and water-scrubbing chambers. Materials and types of construction included steel- or concrete-lined earthen pits, all-steel chambers, and garage-type chambers with steel framework and refractory lining. Many of these incinerators failed or were discarded because of poor design, inadequate materials of construction, or high operating costs.

Consideration of the available information on automobile-incinerators indicated a refractory-lined, garage-type incinerator with a natural gas after-burner and designed for quick loading, burning, and discharge of two cars at a time would meet the requirement of simplicity, relatively low capital and operating costs, and effective smokeless burning of properly prepared cars. A design capacity of six cars per hour was selected. This size incinerator would be capable of burning about 12,500 cars per year that are discarded by a population group of approximately 300,000 people. Areas with such population groups have the greatest need for an automobile incinerator as the accumulation of abandoned cars is significant yet the volume of cars discarded each year is insufficient for a shredder-type plant.

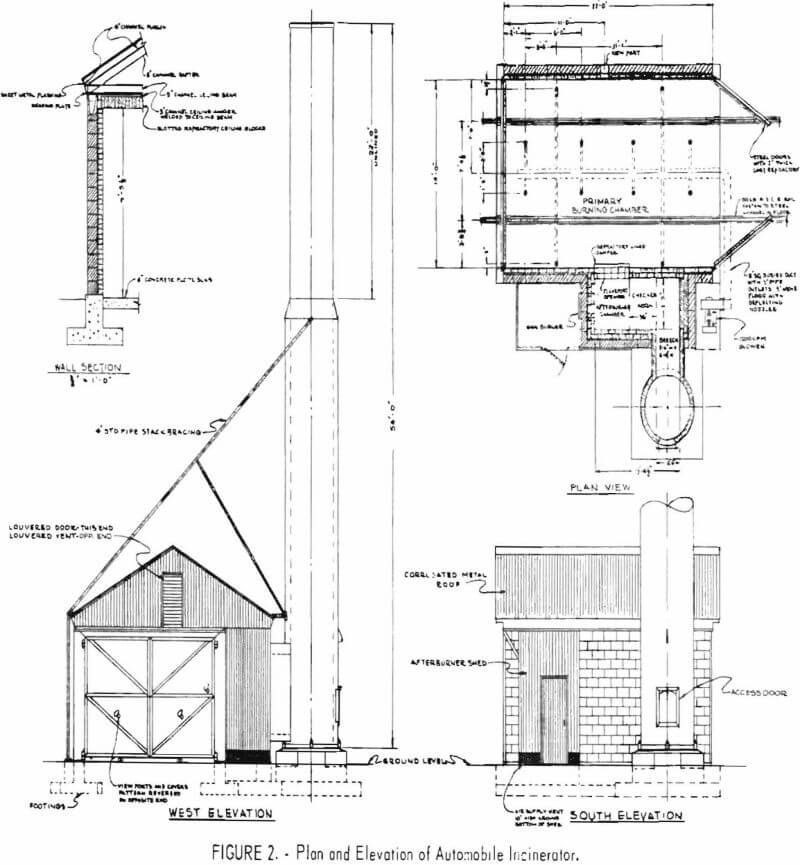

The garage-type incinerator consists of three principal components; (1) A primary burning chamber in which the combustibles are ignited and burned, (2) an afterburner chamber in which the smoke is further heated and consumed, and (3) a stack which creates a controlled draft for drawing in air from below the burning cars in the primary chamber and withdrawing the gaseous products for discharge.

Design

The primary burning chamber is 22 feet long, 14 feet wide, and 9 feet 5 inches high. The chamber has concrete block outer walls, protected by a structural steel framework, single-course refractory brick inner walls, suspended refractory brick ceiling, and a concrete floor with railroad tracks on which the loading cart rides. Castable refractory-lined hinged doors are at either end of the chamber. The gable roof is covered with galvanized steel. There is a small viewing port in the outer wall opposite the afterburner chamber. A castable refractory-lined damper door covers the ceiling-high flame-port opening to the afterburner chamber. The damper is controlled in open or closed vertical positions by a crank and a counter weighted pulley.

The double-course refractory brick-lined afterburner chamber is 9 feet 4-½ inches long, 3 feet 9 inches wide, and 8 feet 3 inches high and has an outer concrete block shell. The afterburner chamber is situated between the primary burning chamber and the stack. A free-standing brick checker work 36 inches deep, 45 inches wide, and 99 inches high-fills the space between the flameport opening and the breech (the short connection between the outlet of the afterburner and inlet of the stack). The checkerwork serves as a heat sink to assist the 6.5-million-Btu-per-hour gas burner in consuming the smoke particles. The burner has five heads and is capable of producing a 1,350° F temperature in the afterburner chamber within 1 hour after starting at ambient temperature.

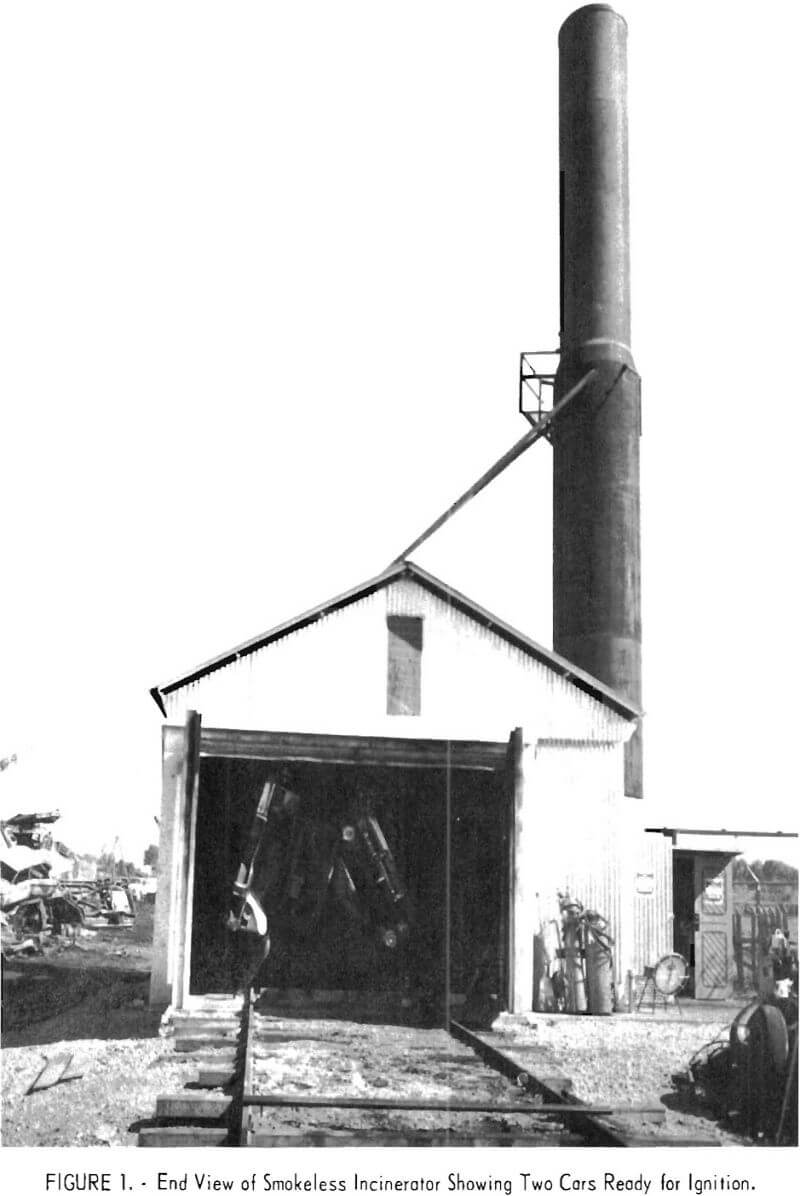

The tapered steel stack is 54 feet high and is partially brick lined. The lower 32-foot steel section of the stack is 5 feet 8 inches in inner diameter and is brick lined with a single course of refractory brick to produce a 4-foot 9-inch inner diameter. The upper 22-foot steel section is unlined and also has a 4-foot 9-inch inner diameter. A picture of the incinerator is shown in figure 1. Schematic drawings showing the main features are given in figures 2 and 3.

Operation

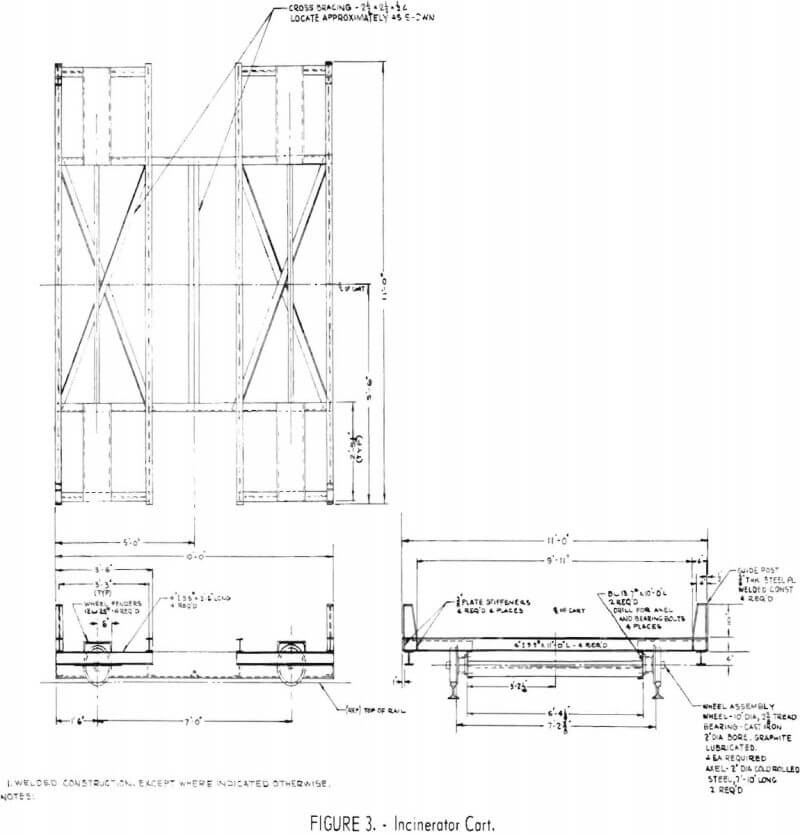

Two cars minus the battery, radiator, wheels and tires, and with gas tanks, oil pan, and sealed shafts punctured, the glass broken out, and the trunk lid sprung open are loaded onto a four-wheel steel cart. The cars are turned on their sides and placed top to top. (Alternatively, the frame, engine, and running gear may be removed and three cars loaded onto the cart.) A small quantity of liquid fuel is splashed onto the cars upholstery as the cart is pulled into the burning chamber and the previously burned charge is removed. The cars are ignited and the smoke drawn through the damper door opening into the afterburner chamber, The sliding port opening, air blower, and door flaps are adjusted to obtain the best burn.

Results of Preliminary Test Runs

After completion of the original basic construction, the incinerator was tested intermittently for approximately 3 months. These test runs were made to determine if the incinerator required modification in design and if it could achieve the required burning capacities with relatively smoke-free burning. Fuel and labor requirements were defined to enable estimating probable operating costs. Some minor modifications of the original construction features were made, principally in the arrangement of the brick checkerwork and the afterburner heads, but the basic structure proved satisfactory as designed.

Based on preliminary tests, the incinerator is capable of burning an average of four cars per hour when the cars are burned with the engine, transmission, frame, and running gear still attached. When the engine and transmission have been removed, the incinerator averages about five cars per hour; if the frame and running gear have also been removed to permit loading three cars at a time, the incinerator will burn an average of 7.5 cars per hour. Optimum operating conditions have not been determined and several operations have not been automated so the throughput of the incinerator probably can be improved.

In a recent continuous operation in which 26 cars were burned, the total incineration time was 378 minutes. The smoke emerging from the stack was observed during this entire period and compared with a Ringelmann chart as to density. These observations indicated that the stack effluent ranged between a No. 1 and No. 3 Ringelmann for a total of 11 minutes. This means that the incinerator produced a stack effluent of No. 1 Ringelmann or less for over 97 percent of the burning period. Other, better controlled continuous incineration periods have produced slightly better results, indicating that the incinerator should meet or exceed most clean air standards.

From the operating data derived in the initial test runs, the preliminary operating cost of the incinerator was estimated as $2.75 per car, plus or minus; 20 percent. This cost estimate is based on 90 percent operating time to burn an average of 215 cars per 40-hour week (11,180 cars per year) in an incinerator that costs $22,000 and is depreciated in 10 years. Direct operating costs are $2.25 per car including $0.80 for gas, electricity, and kerosine, $1.10 for direct labor comprising two men paid at a rate of $3.00 per hour, and $0.35 for maintenance and operating supplies. Indirect operating costs based on factors for administration, overhead, taxes, insurance, and depreciation at 10-percent interest are estimated at $0.50 per car.