The phenomenon of zero order production of fines associated with the batch comminution of monosize feeds in tumbling mills has been examined in the context of the size discretized population balance model. It has been shown that the model admits zero order production kinetics only in an approximate sense. The necessary and sufficient conditions for approximate zero order production of fines have been obtained. As these conditions cannot be expressed in terms of the model parameters Sj and Bi j alone several examples have been used to illustrate some of the important characteristics of the zero order production systems. One of the important characteristics of these systems has been identified as a”weak necessary condition”, and the other as a ” favourable condition “.

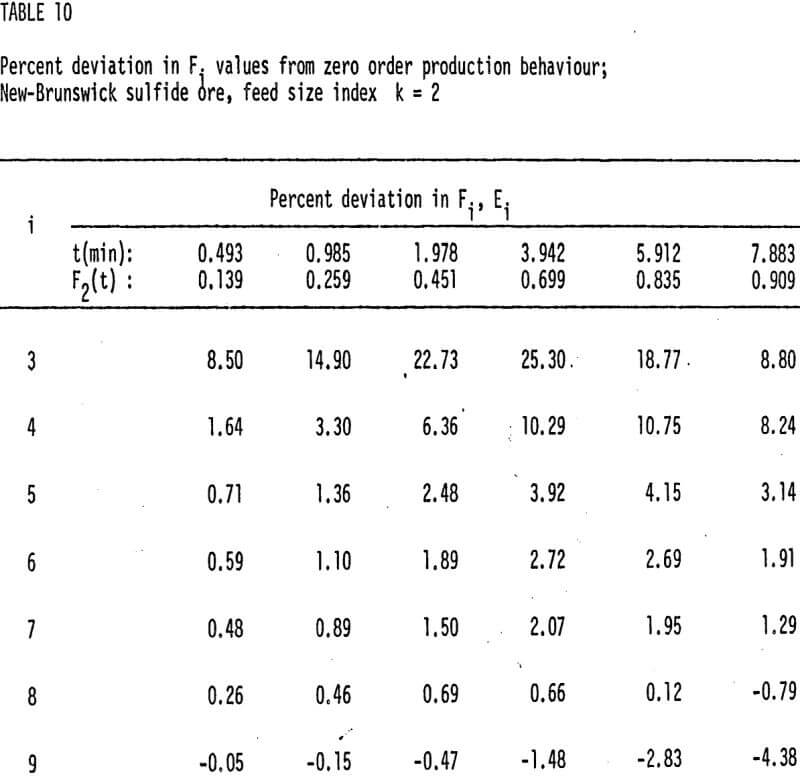

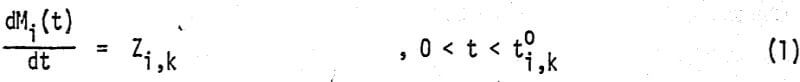

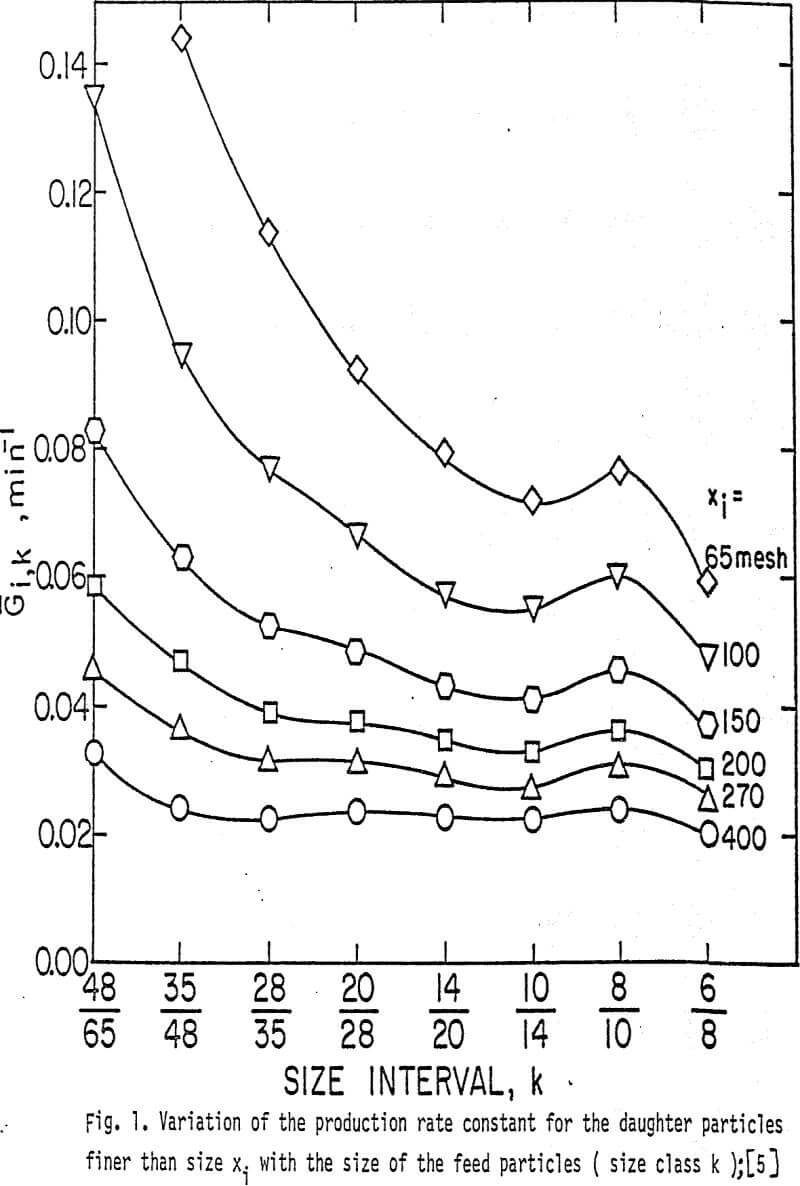

where Mi is the mass fraction of the particulate material in the i-th sieve size interval corresponding to the size range xi < x < xi-l ; Zi, k is a rate constant associated with the initial production of particles of size class i from a starting monosize feed of size class k; t is grinding time; and ti k denotes a time limit up to which eqn. (1) can be regarded to be approximately valid.

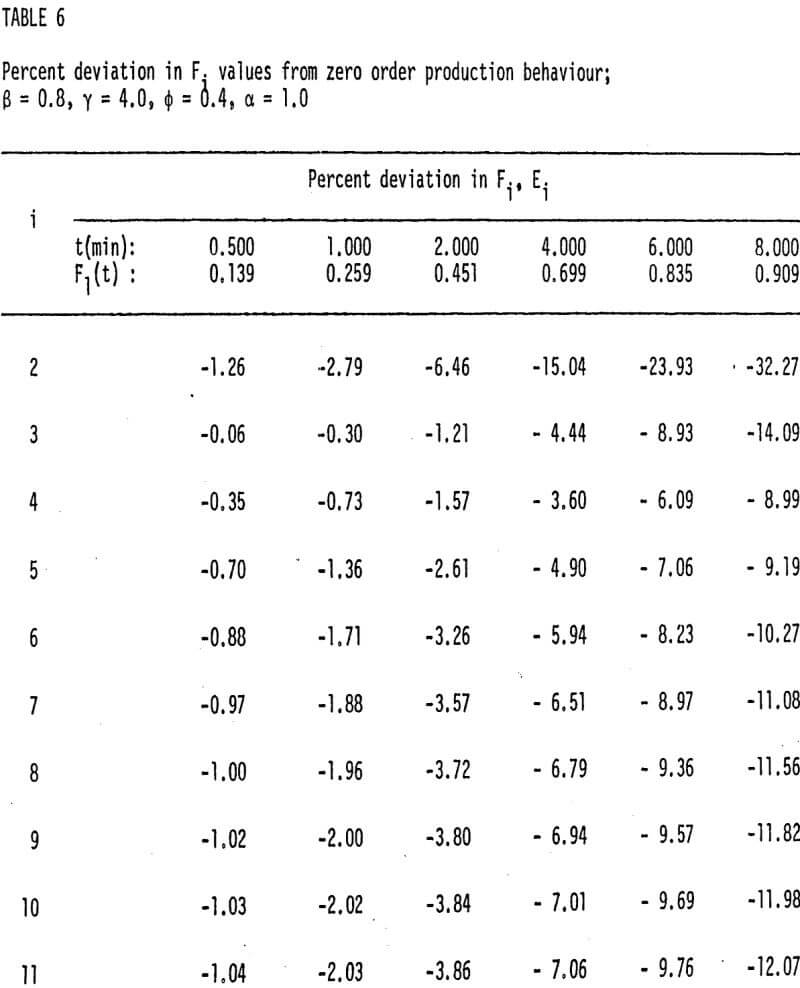

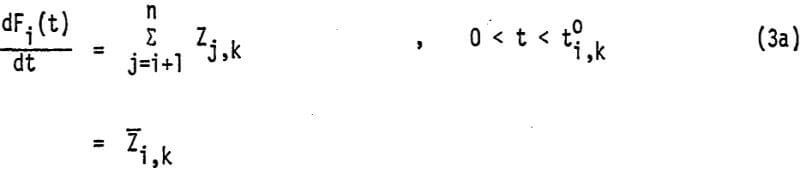

An alternative mathematical representation of the zero order production phenomenon can be made in terms of Fi, the mass fraction of the particulate material finer than size xi. By definition

where size index n denotes the finest size interval. From eqns. (1) and (2) we obtain

Zi, k is, therefore, the zero order production rate constant for the particulate material finer than size xi.

It should be pointed out that the amount of coarser particles decreases continuously with time from the very beginning. Also, it has now been well established using feeds of widely different size distributions that in dry ball mill grinding the specific grinding rate of a size fraction is practically independent of the amount of coarser particles.

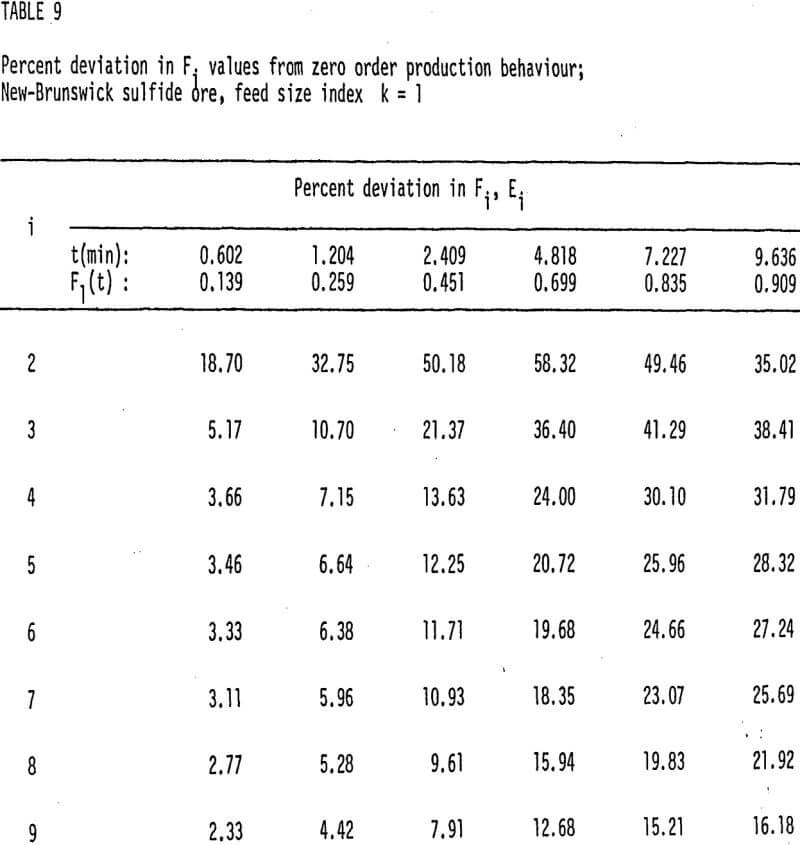

Besides the dry ball mill grinding operation, the zero order production phenomenon has been observed for wet ball mill and dry and wet rod mill grinding operations also. In fact, the production plots given by different investigators very clearly show that the zero order production behaviour is more prominent in case of these operations than it is generally, observed in dry ball milling operation. It may be recalled that grinding in rod mills and wet ball mills is characterized by time dependent rates of breakage. Especially, in case of rod milling, due to preferential grinding of the coarsest particles by the rods, significant variations in the grinding rate parameters with grinding time are expected for the particles in the upper size intervals. .

Analysis of the Population Balance Equation for Zero Order Production

It has been reported that the batch rod milling and wet ball milling operations are characterized by time dependent grinding rates (S values increasing with time), at least for the first few coarsest size intervals.

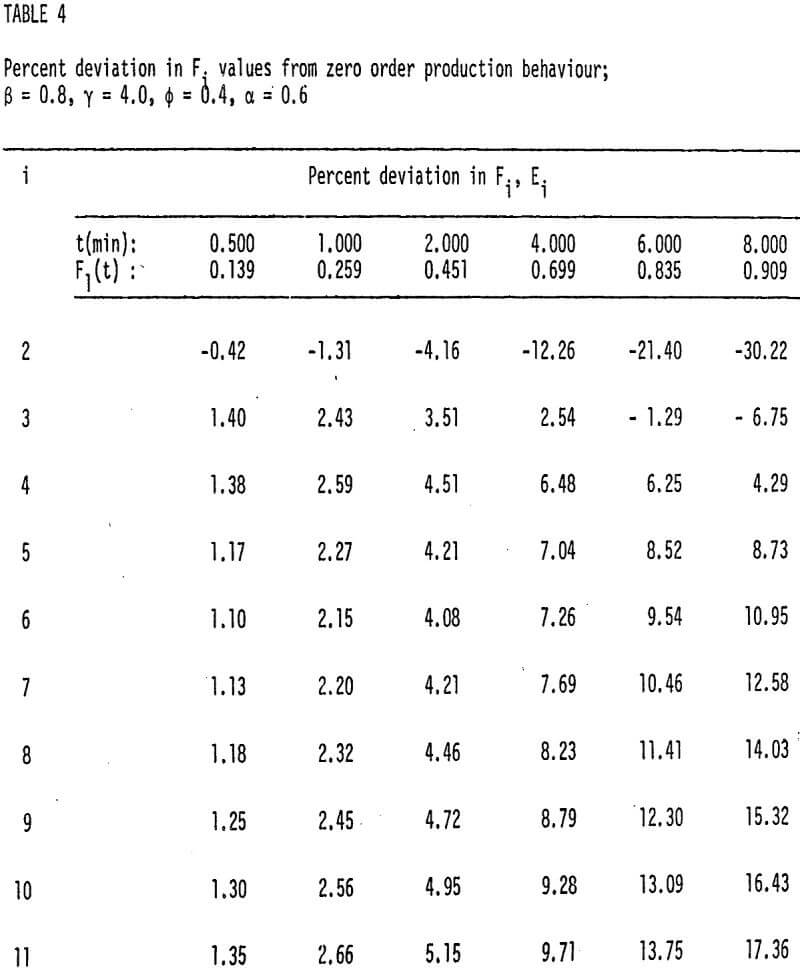

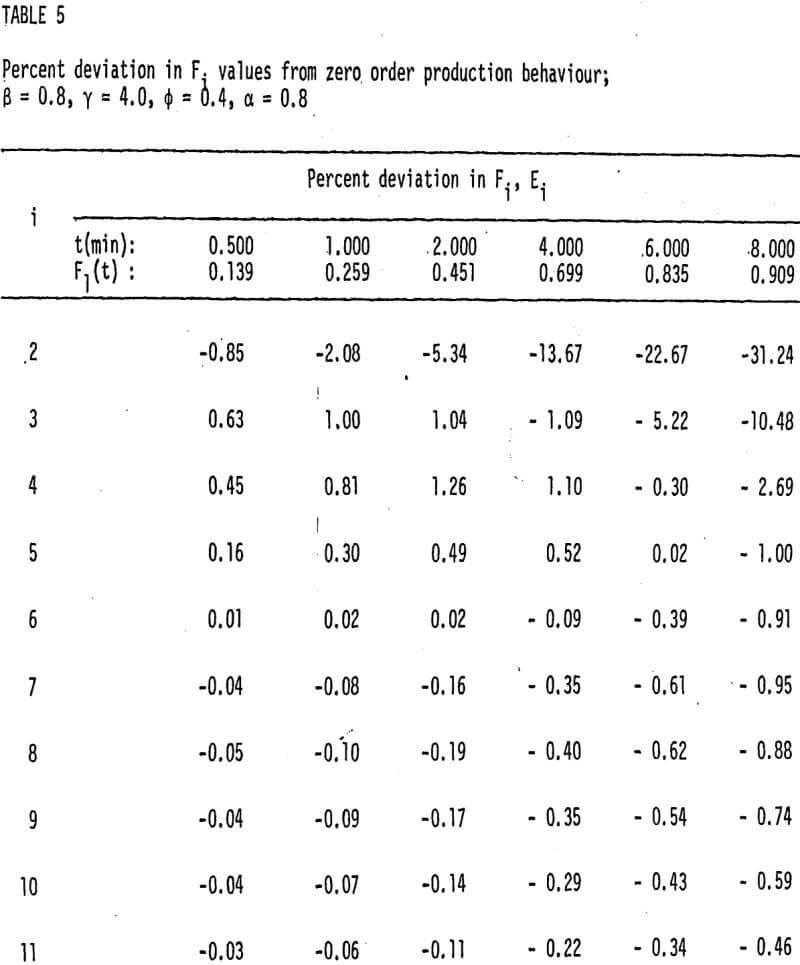

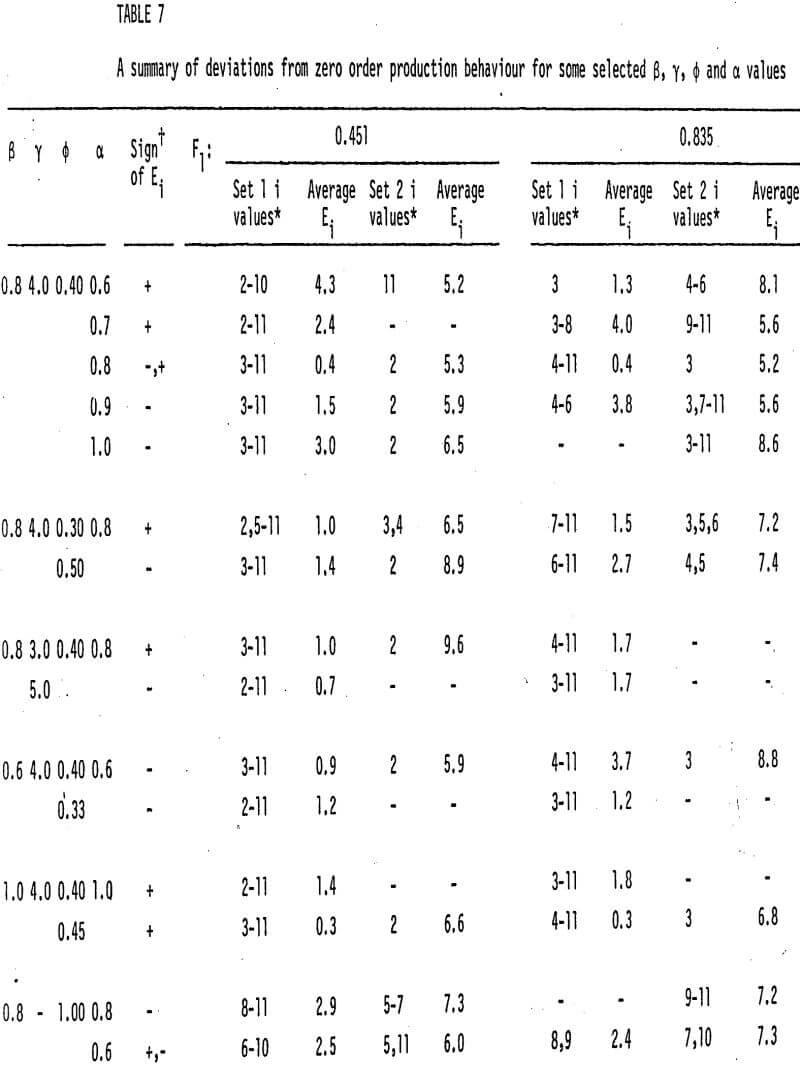

- For a good zero order production of all sizes, the following two conditions must be satisfied:

(a) Gi, j> Gi k for at least one j: k+l≤j≤i

Generally this condition should be satisfied for two or more j values.

(b) Gi, j∼ Gi k for some of the coarsest j size intervals ( j= k+1, k+2,)

This condition is more important for the finer sizes. - In most of the cases the above mentioned second conditions cannot be satisfied if one or more Si values are greater than Sk. Therefore, over the particle size range of interest, the S values must increase monotonically with the particle size.