Table of Contents

The dies can be identified by removing the cap and observing the die body. The standard die will have a smooth cylinder, where the premium die will have a cutout for the accommodation of a plastic ring. Remove the ring from the die and extend the die shaft until it clicks into place. The shaft can also be removed completely for cleaning. If the shaft is removed, simply insert it back into the die body. When extending, the die will support itself and can be placed unto the table. Insert the funnel into the die. Using the 10-mil sample spoon, measure out a portion of your sample to place into the die. A dry, fine powder will produce the best results.

The dies can be identified by removing the cap and observing the die body. The standard die will have a smooth cylinder, where the premium die will have a cutout for the accommodation of a plastic ring. Remove the ring from the die and extend the die shaft until it clicks into place. The shaft can also be removed completely for cleaning. If the shaft is removed, simply insert it back into the die body. When extending, the die will support itself and can be placed unto the table. Insert the funnel into the die. Using the 10-mil sample spoon, measure out a portion of your sample to place into the die. A dry, fine powder will produce the best results.

Introduce the sample into the funnel. If bridging occurs or the sample does not flow completely into the die, tap the funnel and/or die body lightly. When using the standard sample die, the volume is less critical because it is possible to produce pucks of varying thickness.

When using the premium die, at this stage you will insert the plastic ring into the die. The rings are tapered and will only fit into the die in one direction. If the ring does not insert fully, flip the ring over. Using the 10-mil sample spoon, measure out a portion of your sample to place into your die.

Place the lid unto the die and turn to lock the lid. Only turn so that the pin is engaged in the slot. Do not tighten, as the lid can become locked. Do not press down on the die until the lid is in place and latched.

The sample is now ready to be pressed. The press uses hydraulic pressure to press the sample and operates at high pressures. When pressurized, do not touch any hoses or fittings. Unlatch the door to the press and place sample die into the press. Insert the die fully, utilizing the provided guides.

Close and latch the door. Turn the cap to vent. Unlatch the handle locking mechanism and ensure the pressure relief valve is closed and begin to pump. Use full strokes of the pump when pumping to ensure the second stage of the pump is activated.

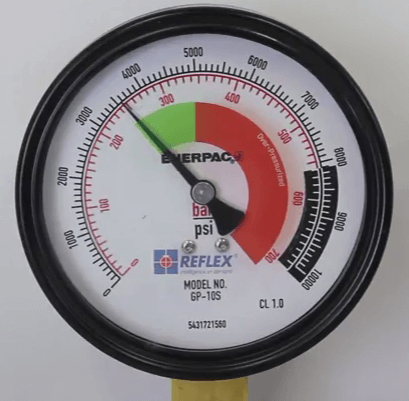

Observe the pressure gauge and increase pressure until the needle is in the green zone as indicated by the gauge. The pump is regulated to provide up to 5000 PSI. However, ensure that this pressure is not exceeded. Pressure will decrease slightly as the sample is compacted. Once it is stabilized, approximately 5-10 seconds, the pressure can slowly be released by opening the relief valve. Allow the pressure to release fully. Once released and the cylinder is fully retracted, open the door and remove the die.

Remove the cap off the die. If you’re using the standard die, the sample is ready to be pressed out. If you’re using the premium die, grasp the die body and pull the shaft while twisting to extend the die, then reinsert. This loosens the ring from the shaft and makes removal easier. Close and letch the door. Close relief valve and begin pumping.

The die will rise against the top of the press and the sample will be progressively pressed out of the die. During this process, observe the pressure gauge. The pressure should not exceed a few hundred PSI. If it does, check everything is in order before continuing. Once the sample is completely free of the die, open the pressure relief valve.

Once the cylinder is fully retracted, remove the die, remove the sample, clean and repeat.

The step for the use of the premium sample die are the same as those used with the basic die, except the ring is in place. A variety of cleaning tools are provided in the accessories case. Use these tools to clean excess material form the die parts between runs to minimize contamination.

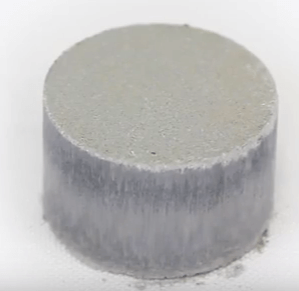

The denser, flatter, a more uniform puck provides a more reliable surface from which to gain a quality analysis. With no film required between the XRF analyzer and the sample, the risk of a weaker or poor signal is eliminated. The same puck can also be used with other non-destructive testing techniques such as spectral analysis and LIPS.

The Reflex Press, delivering better data at lower cost with increased productivity. Better data, lower cost, increased productivity.

Optimal pXRF sample analysis relies on a homogenous, densely packed and uncontaminated sample puck. The risks inherent in decisions made on unreliable sample data, are significant and may include the misrepresentation of traces of ore either present or missing.

There are a wide variety of techniques for sample preparation for XRF analysis and the use of XRF cups is common. However, these tend to be expensive, fiddly and time consuming, and very hard to control the sample quality [poor packing, uncompacted].

REFLEX has addressed these risks in the REFLEX PRESS. The innovative sample press is a high-pressure hydraulic press designed to produce a densely-packed, homogenous, sample puck that can be measured by the pXRF [and a range of non-destructive sensors] without the signal attenuation resulting from the use of a film coating and/or poor packing.

The REFLEX PRESS is safe and reliable, engineered and constructed using only high quality, fit for purpose, products. It is also rugged and portable, ideal for use in field camps and onsite laboratories.

Decreased cost of consumables

The REFLEX PRESS uses high pressure to convert powders to a coherent pressed puck without the need to use binders or costly containers. Removing the need to use sample cups equates to savings of up to $150 per day.

Increased Productivity

The custom designed die set and press provide a simplified process with fewer steps, allowing productivity to be increased, with consistency across all samples.

Accurate data

The denser, flatter and more uniform puck provides a more reliable surface from which to gain a quality analysis. With no film required between the pXRF analyser and sample, the risk of a weaker or poor signal is eliminated. The same puck can also be used with other non-destructive testing techniques such as spectral analysis and LIBS.

Improved Analytics

The REFLEX PRESS comes with a custom designed funnel and sample die to ensure the highest quality, consistent and repeatable, sample puck ensuring data confidence and improved analysis, especially for light elements.

Using the pressed puck and the REFLEX XRF, light elements such as Al have a consistently higher response (8-15%). This will flow through to decreased detection limits and better precision for light elements. The consistent workflow of the REFLEX PRESS will also reduce inter-sample variation resulting from poor packing of material and other inconsistencies, making data analysis more reliable.

Transportable

The REFLEX PRESS is light in weight compared to other commercial sample presses, being under 30kg. It can be safely transported in a robust and easy to pack, protective case.

In-field Geoanalysis

The REFLEX PRESS together with the REFLEX XRF Solution (which includes REFLEX XRF, REFLEXHUB-IQ and REFLEX ioGAS) provides the first on-site geoanalysis solution available in the market. This enables decisions to be made on-site, saving both time and money.

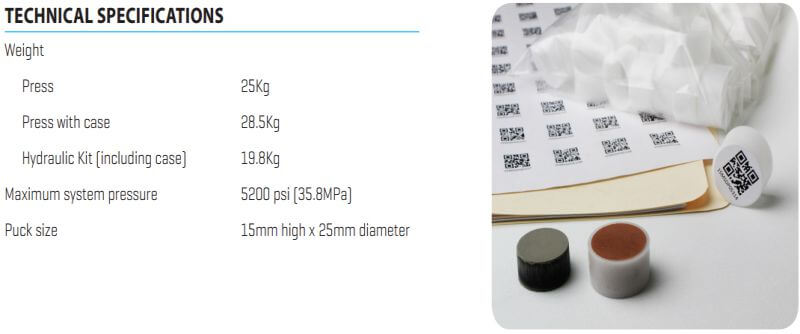

Standard or Premium Puck

The REFLEX PRESS is provided with two separate dies for the making the puck. The STANDARD puck is produced without a protective sleeve and is most useful for minimising costs when the sample will be discarded after analysis, or analysis is performed immediately after pressing. The PREMIUM puck is produced within a custom plastic sleeve that makes the sample very robust for longer term storage, potential re-assaying or archive, and reduces cleaning time after each sample. The plastic sleeves are sold in boxes of 500 and can be easily labelled for reference.