Table of Contents

- Rugged – SHOCKPROOF

- Revolutionary

- Productive

- Scrap Sorting

- Regulatory and Safety Screening

- Geochemistry and Mining Exploration

- Jewelry/Precious Metals ID

- Research and Education

- Environmental Assessments

- Axon XRF Analyser Technology

- VMR Limits of Detection GeoChem

- VCR Limits of Detection GeoChem

- XRF Analyzer Specifications

- The Vanta Series

- VANTA XRF Specifications

- VANTA Mining

- Mineral Exploration

- Ore Grade and Process Control

- Durable and Reliable

- Vanta Analyzers for Mining

- Shock Resistant XRF Analyzer

The new 911MPEVanta XRF analyzer is our most advanced handheld X-ray fluorescence (XRF) device. These rugged, powerful, and intuitive instruments provide rapid, accurate element analysis and alloy identifications to customers who demand laboratory-quality results in the field.

Vanta handheld XRF analyzers are some of the toughest devices ever made. Their rugged and durable design makes them resistant to damage for greater uptime and a lower cost of ownership. With intuitive navigation and configurable software, the Vanta series are easy to use with minimal training for high throughput and fast return on investment. Olympus’ innovative Axon technology means Vanta analyzers give you accurate results and help boost productivity no matter the environment or working conditions.

- Exceptional durability under extreme conditions

- Analytical excellence

- Optional Wi-Fi and Bluetooth for real-time data sharing

- Intuitive user interface

Rugged – SHOCKPROOF

Working conditions can be tough on electronic devices, often causing breakdowns that cost time and money. Vanta analyzers are durable for increased uptime and a low cost of ownership. The Vanta series are drop tested using U.S. Department of Defense methods (MIL-STD-810G), reducing the risk of damage and costly repairs when a device is dropped or jostled.

Vanta devices are also IP 65 rated dust and water resistant to protect against the hazards found in even the most challenging environments. Able to withstand a temperature range of -10 °C to 50 °C (14 °F to 122 °F) at full duty cycle, Vanta analyzers ensure you achieve 100% uptime without wasting time waiting for your analyzer to cool, even in hot environments. The detector shutter on C and M series models helps prevent punctures so you can analyze rough surfaces with confidence.

Revolutionary

Every circuit, contour, and interface of Vanta handhelds is engineered to be the best of its kind. Vanta analyzers incorporate the new Axon technology, a breakthrough in XRF signal processing that delivers accurate and repeatable test results. Axon uses ultra-low-noise electronics enabling higher X-ray counts per second and faster results. Coupled with a new quad-core processor, Axon makes Vanta analyzers remarkably responsive, pushing the limits of performance so you get the best results in the least amount of time. Axon technology provides both test-to-test and instrument-to-instrument repeatability. Whether it’s your first test on your first analyzer or your thousandth test with your hundredth analyzer, the Vanta handheld XRF gives you a consistent result.

Productive

Productive

Vanta analyzers maximize user throughput and make data archiving easy. Application-specific software features improve user productivity for fast ROI.

- A new, intuitive interface (UI) enables the user to quickly navigate the device’s settings and software functions.

- The UI can be configured based on a customer’s specific needs. Users can customize which software features and functions are displayed on the main screen.

- Data are easily exported via a USB flash drive, Wi-Fi, or Bluetooth. Vanta analyzers are designed to enable powerful cloud applications.

- Vanta analyzers feature a clear, bright LCD touch screen that is readable in any light.

- Ergonomic buttons and an industrial-grade, push-button joystick enable users to easily navigate the system with gloved hands.

Olympus’ Vanta handheld XRF offers embedded GPS so users can pair results with precise GPS coordinates to document and map the location of elements. The optional 5-megapixel panoramic camera combines images of XRF data with GPS coordinates for inclusive archiving and streamlined reporting which provides unmatched data traceability to the field.

Olympus’ Vanta handheld XRF offers embedded GPS so users can pair results with precise GPS coordinates to document and map the location of elements. The optional 5-megapixel panoramic camera combines images of XRF data with GPS coordinates for inclusive archiving and streamlined reporting which provides unmatched data traceability to the field.

Vanta analyzers provide fast results in a diverse range of applications from alloy identification (ID) to archaeological site evaluation. Olympus’ range of application-specific software features enable operators to get the most out of their analyzers with simplified report creation and traceable results.

Scrap Sorting

Vanta analyzers for scrap sorting feature a SmartSort function that intuitively lengthens or shortens test times based on material to save time while providing the best possible match. The software automatically compares results to a library of alloy compositions to quickly match unknown materials to known alloys. The Grade Match Messaging feature enables users to program messages for each grade to display warnings or instructions. These messages make it easy for operators to use the analyzer with little training, putting the knowledge of your most experienced person to work for everyone.

Positive Material Identification (PMI) and Manufacturing Quality Control/Assurance

Vanta analyzers help ensure that refineries, petrochemical plants, and other processing facilities are safe by verifying that correct alloys are installed in critical locations by following American Petroleum Institute Recommended Practice 578 (API-RP-578). Manufacturers and installers of expensive or mission-critical components and machinery can rest easy knowing that they are manufactured with the correct alloy grades, regardless of the material source. The Vanta series’ integrated GPS, optional panoramic camera, user-defined input fields, connectivity features, and extensive data reporting capabilities maximize inspector confidence and traceability to the field.

Regulatory and Safety Screening

The Vanta series screens for Pb, Cd, As, Hg, Cr, and other toxic metals in consumer products such as toys, apparel and footwear, and electronics to comply with RoHS regulations. With an optional camera, Vanta handhelds automatically archive sample images and results, making it the ideal tool for a reasonable testing program. Excellent sensitivity enables it to achieve low detection limits for pass/fail results of regulated elements.

Geochemistry and Mining Exploration

The Vanta handheld analyzer is the preferred tool for mining exploration including surface mapping and core analysis. It provides accurate and reproducible results in any environment. Vanta analyzers work all day even in the high temperatures found in desert or jungle environments; remote areas where instrument downtime cannot be afforded. Geo- referenced XRF data transfer wirelessly, via Bluetooth or WiFi, for real-time geochemical mapping on a GIS-equipped tablet or laptop. Map, visualize, assess, and follow-up on targets in the field for faster in-field geological exploration and decision-making.

Jewelry/Precious Metals ID

Vanta analyzers can provide on-the-spot characterization of a range of jewelry and precious metals including Au, Ag, Pt, and Pd. The analyzer accurately classifies the purity of gold alloys (0-24 karat) and can also detect plating. With the high price of precious metals, return-on-investment is rapid.

Research and Education

Vanta instruments provide quantitative, semi-quantitative, and qualitative elemental information to guide research and identification of unknown or complex materials. Fast results keep students engaged with relevant data in applicable science-based projects.

Environmental Assessments

The Vanta analyzer readily screens soil and other materials for pollutant metals. Paired with GPS data, the results can be wirelessly transferred to a GIS to create pollutant metal maps. Get fast, decisive results for site characterizations, assessments, property evaluations, and contamination tracking.

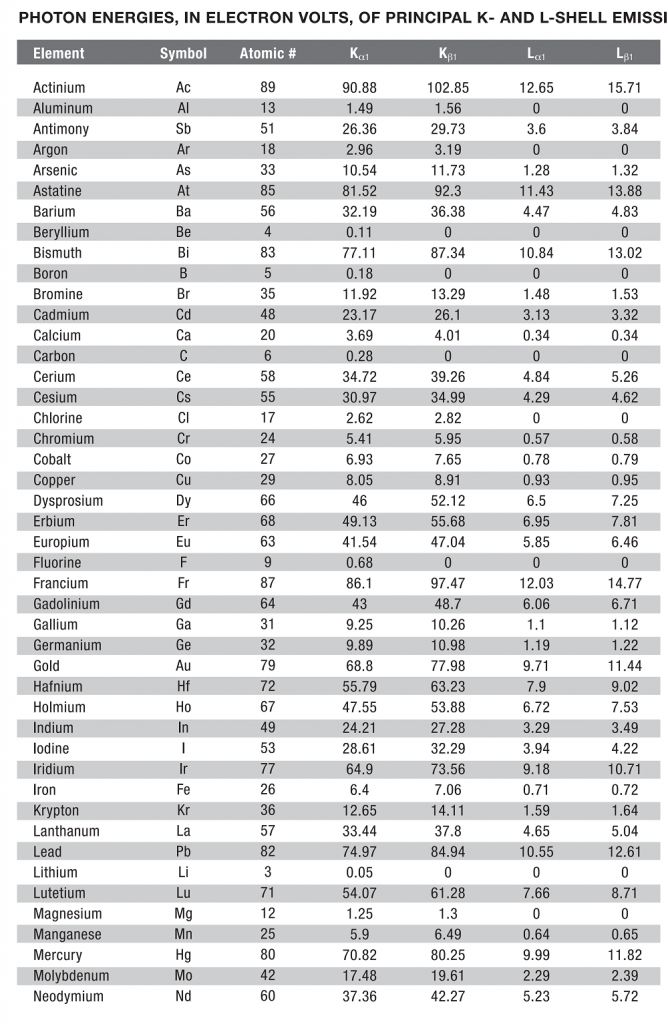

Axon XRF Analyser Technology

Olympus’ new Axon technology features enhanced XRF signal processing for accurate, repeatable test results. Axon technology’s use of proprietary ultra-low-noise electronics pushes the boundaries of X-ray detector performance, resulting in higher X-ray counts per second and faster, more reliable results. Analyzers powered by Axon technology give confidence to the user by delivering the ultimate test-to-test and instrument-to-instrument repeatability. Experience the difference that Axon technology makes.

Higher X-ray count rates

Higher X-ray count rates translate to faster test results, better precision, and lower limits of detection. Optimizing one detector parameter (such as peaking time or count rate) typically results in significant deterioration of other parameters (such as resolution). Axon technology minimizes this challenge; Vanta analyzers are set up to process more X-ray counts for faster and more precise results.

Ultra-low electrical noise design

Even with shorter peaking times, Axon technology delivers a breakthrough in resolution that is better than other XRF analyzers—resolution approaching fundamental theoretical limits. This outstanding

resolution enables our devices to clearly separate crowded spectral peaks. This feature is important for the quantification of light elements for alloy or for geochemical samples and precious metals that were

difficult to measure before the introduction of Axon technology.

Automatic energy scale calibration method doesn’t require a calibration sample

Many XRF analyzers only check the energy scale at startup and/or periodically through the use of an internal or external sample. With Axon technology, the analyzer automatically checks the energy scale in microseconds before every test so you can trust your results every single time. The stable energy scale provided by this check enables repeatable results, meaning you get the same answer when you first turn on the analyzer as you do on your 500th test on a hot day. Axon technology limits the drift of analytical results as the analyzer or ambient temperature varies, a problem many handheld XRF devices suffer from.

Patent pending reset scheme enables higher throughput and lower detector dead time

Axon technology’s innovation enables the analyzer to count more of the X-rays that the detector encounters, a capability that is unavailable on most other XRF analyzers. Proprietary processing algorithms mean that pileup counts (a phenomenon when two or more X-rays hit the detector at the same time) are discarded faster, so the analyzer is ready for the next X-ray, maximizing the efficiency of the detector.

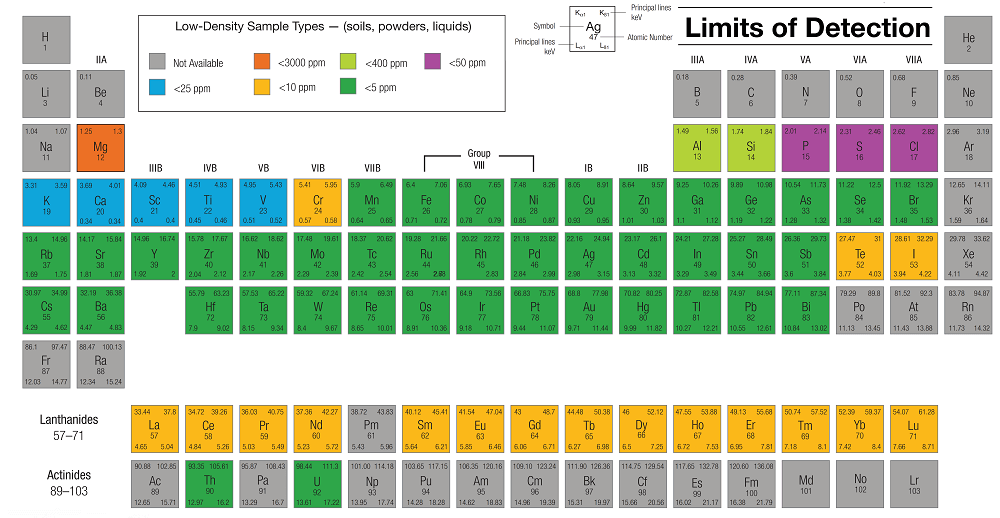

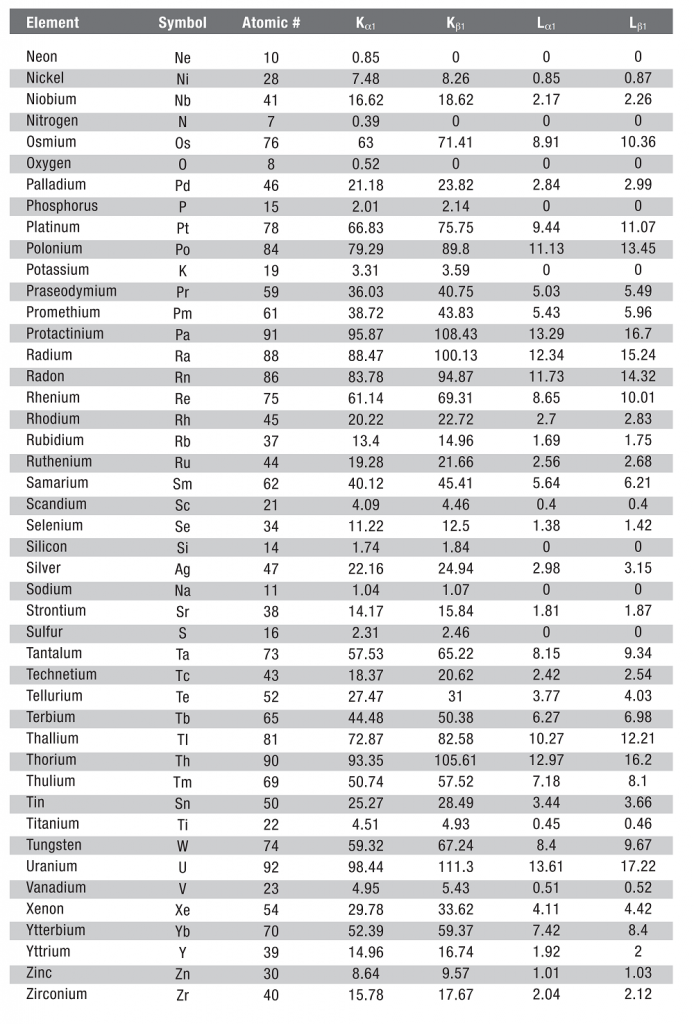

VMR Limits of Detection GeoChem

Olympus is a leader in XRF technology with a reputation for durability, quality, and accuracy. Vanta handheld XRF analyzers incorporate Olympus’ Axon technology to deliver higher X-ray counts and high sensitivity for analysis of all types of mineral exploration, mining, processing/metallurgical, laboratory, and environmental samples.

Every Vanta analyzer is drop tested, features Olympus’ Axon technology, and is rugged, fast, and reliable.

Vanta analyzers are capable of measuring elements from concentrations as low as single parts per million (ppm) all the way up to 100%.

The Limits of Detection (LOD) represent the calculated value using a three sigma 99.7% confidence level. The LOD for each element is a function of the testing time. Please contact your local Olympus representative for more information.

The LOD table gives an indication of the performance of the Vanta model VMR across many elements and sets of certified standards.

- LODs were developed by testing a variety of certified reference materials or standards.

- LODs are dependent on testing time, sample heterogeneity, the presence/absence of interfering elements, and the beam conditions used (kV and pA of the X-ray tube and filter settings).

- All values are determined using multiple automatically selected beam conditions.

- The LOD is the lowest quantity of an element that can be detected in an interference-free silica blank.

- There are many commonly known inter-element interferences, such as iron (Fe) on chromium (Cr), titanium (Ti) on barium (Ba), and lead (Pb) on arsenic (As). Please contact your Olympus representative for more information.

- Analysis time is 120 seconds per beam condition.

- Only the common elements are listed, other elements are possible.

- Additional information regarding gold (Au) analysis:

– Gold naturally forms clumps or ‘nuggets’ and is not evenly distributed in the sample. Reported values will be high compared to lab assay when a nugget is in the X-ray beam and low if the nugget is missed.

– Gold has multiple inter-element interferences including arsenic (As), zinc (Zn), tungsten (W) and selenium (Se). Therefore, gold (Au) results might be either over-reported (false-positives) or under-reported (not detected). The use of pathfinder elements is recommended for gold exploration.

VCR Limits of Detection GeoChem

VCR Limits of Detection GeoChem

Olympus is a leader in XRF technology with a reputation for durability, quality, and accuracy. Vanta handheld XRF analyzers incorporate Olympus’ Axon technology to deliver higher X-ray counts and high sensitivity for analysis of all types of mineral exploration, mining, processing/metallurgical, laboratory, and environmental samples.

Every Vanta analyzer is drop tested, features Olympus’ Axon technology, and is rugged, fast, and reliable.

Vanta analyzers are capable of measuring elements from concentrations as low as single parts per million (ppm) all the way up to 100%.

The Limits of Detection (LOD) represent the calculated value using a three sigma 99.7% confidence level. The LOD for each element is a function of the testing time. Please contact your local Olympus representative for more information.

The LOD table gives an indication of the performance of the Vanta model VCR across many elements and sets of certified reference materials.

- LODs were developed by testing a variety of certified reference materials or standards.

- LODs are dependent on testing time, sample heterogeneity, the presence/absence of

interfering elements, and the beam conditions used (kV and pA of the X-ray tube and

filter settings). - All values are determined using multiple automatically selected beam conditions.

- The LOD is the lowest quantity of an element that can be detected in an interference-free silica blank.

- There are many commonly known inter-element interferences, such as iron (Fe) on chromium (Cr), titanium (Ti) on barium (Ba), and lead (Pb) on arsenic (As). Please contact your Olympus representative for more information.

- Analysis time is 120 seconds per beam condition.

- Only the common elements are listed, other elements are possible.

- Additional information regarding gold (Au) analysis:

– Gold naturally forms clumps or ‘nuggets’ and is not evenly distributed in the sample. Reported values will be high compared to lab assay when a nugget is in the X-ray beam and low if the nugget is missed.

– Gold has multiple inter-element interferences including arsenic (As), zinc (Zn), tungsten (W) and selenium (Se). Therefore, gold (Au) results might be either over-reported (false-positives) or under-reported (not detected). The use of pathfinder elements is recommended for gold exploration.

XRF Analyzer Specifications

Vanta handheld XRF analyzers are rugged and built for analytically demanding applications in the harshest environments. Vanta analyzers are IP 65 rated for protection against dust and water, are drop tested, and built to withstand a temperature range of -10 °C to 50 °C (14 °F to 122 °F).

Vanta analyzers provide fast, accurate elemental analysis. Each device features Olympus’ new Axon technology, a revolution in XRF signal processing that provides accurate, repeatable results for greater productivity and a fast return on investment. Vanta analyzers feature an intuitive interface and application-specific software so new users can work with the device with minimal training. Data is easily exported via Wi-Fi, Bluetooth, or USB.

The Vanta Series

No matter the model, each Vanta analyzer is engineered for durability and analytical superiority. Olympus manufactures Vanta analyzers to suit a variety of applications depending on your needs.

M Series

Our most powerful Vanta analyzers feature exceptional performance to handle the most demanding applications. Each M Series analyzer comes equipped a large-area silicon drift detector, your choice of either a rhodium (Rh) or a tungsten (W) anode, and a 50 kV X-ray tube.

C Series

The C Series combine value with superior speed, limits of detection (LODs), and elemental range. Each C Series analyzer is equipped with a silicon drift detector and your choice of an Rh or W anode 40 kV X-ray tube, or a silver (Ag) anode at 50 kV X-ray tube.

VANTA XRF Specifications

| Dimensions (W × H × D) | 8.3 cm × 28.9 cm × 24.2 cm (3.25 in. × 11.4 in. × 9.5 in.) |

| Weight | 1.70 kg (3.75 kb) with battery, 1.48 kg (3.25 lb) without battery |

| Excitation Source | 4-Watt X-ray tube with application optimized anode material (rhodium (Rh), silver (Ag), or tungsten (W))

M Series (Rh & W) and C Series (Ag): 8–50 kV C Series (Rh & W): 8–40 kV |

| Primary Beam Filtration | 8-position auto selected filter per beam per mode |

| Detector | M Series: Large area Silicon Drift Detector

C Series: Silicon Drift Detector |

| Power | Removable 14.4 V Li-Ion battery or

18 V power transformer 100-240 VAC, 50–60 Hz, 70 W max |

| Display | 800 × 480 (WVGA) LCD with capacitive touch-screen supporting gesture control |

| Operating Environment | Temperature: -10 °C to 50 °C (continuous duty cycle with optional fan)

Humidity: 10% to 90% relative humidity non-condensing |

| Drop Test | Military Standard 810-G 4-foot (1.3 M) drop test |

| IP Rating

|

M Series IP 64: dust tight and protected against water splashing from all directions

C Series IP 65: dust tight and protected against water jets from all directions |

| Pressure Correction | Built-in barometer for automatic altitude and air density correction |

| GPS | Embedded GPS / GLONASS receiver |

| Operating System | Linux |

| Data Storage | 4 GB embedded storage, micro SD slot for expandable storage |

| USB | (2) USB 2.0 type A host ports for accessories such as Wi-Fi, Bluetooth, and USB flash drives.

(1) USB 2.0 type mini-B port for connection to computer. |

| WiFi | Supports 802.11 b/g/n (2.4 GHz) via optional USB adapter |

| Bluetooth | Supports Bluetooth and Bluetooth Low-Energy via optional USB adapter |

| Aiming Camera | Full VGA CMOS camera |

| Panoramic Camera | 5-megapixel CMOS camera with autofocus lens |

VANTA Mining

The Olympus Vanta handheld XRF provides immediate, on-site elemental measurements for a range of geochemical applications. Vanta analyzers provide power and flexibility across the entire mineral resource cycle:

- Greenfield and brownfield exploration

- Ore grade and process control

- Environmental monitoring and remediation

- Academic/educational research and teaching within the geological/environmental sciences

Every Vanta handheld XRF is IP 65 rated to withstand rain, dirt, and dust and are drop tested to department of defense standards (MIL-STD-810G) to help prevent breakages and costly repairs. Their rugged and durable design makes Vanta devices resistant to damage for greater uptime and a lower cost of ownership.

With our innovative new Axon technology, you get the right answer no matter the environment or working conditions. Vanta analyzers for geochemistry feature software designed in cooperation with industry experts to help meet the needs of mineral resource, environmental companies, and educational institutions. Integrated GPS enables users to instantly geo-reference exploration and environmental samples. Connectivity via Wi-Fi and Bluetooth gives users the flexibility to send results to base in real-time and seamlessly integrate data into third-party geological software programs. Vanta analyzers also offer onboard spectra viewing to quickly discriminate spectral overlaps.

Vanta XRF analyzers are effectively used across a range of mineral deposit types including:

- Base metals such as Cu, Pb, Zn, Ag, and Mo

- Gold, including pathfinders, and litho-geochemistry

- Uranium +/- rare earth elements and pathfinders

- Nickel sulfide and laterite deposits

- Iron ore and bauxites

- Rare earth elements (REEs) such as La, Ce, Pr, and Nd

- REE pathfinders including Y, Th, and Nb

- Phosphates, potash, limestone, magnesite, and other industrial minerals

- Epithermal Sn, W, Mo, Bi, and Sb deposits

- Mineral sands such as Ti and Zr

- Coal, oil, and gas through mud logging and trace element chemistry

Mineral Exploration

Vanta analyzers offer rapid return on investment (ROI) by providing users with “decision quality” geochemical data much faster than traditional laboratory techniques. Rapid, accurate decision-making at the exploration stage enables field time to be used more effectively, maximizes exploration (drilling and analytical) budgets, and advances project timeframes.

Vanta analyzer’s easy-to-use interface can be customized with settings useful for specific sites, users, projects, and applications. Geologists can store multiple sample and matrix-specific calibration models for optimal performance depending on the minerals of interest at the specific site.

The durable design and advanced Axon technology found in every Vanta analyzer enables geologists to work in remote areas with confidence that the device is built to withstand harsh environments and that answers provided are reliable and repeatable. In mineral exploration applications, Vanta analyzers are effective for:

- Due diligence during property acquisition

- Analyzing the qualitative chemistry of rock, chip, soil, and sediment samples at the early regional reconnaissance and mapping stages

- Gathering quantitative data during first-pass regional soil, sediment, till, and trenching stages

- Identifying mineralized trends and anomalies, defining drill targets, and extending soil sample lines

- Adapting sampling and mapping programs in real-time to maximize exploration budgets

- Pre-screening samples to maximize the efficiency of off-site laboratory testing

- Increasing sample density in the most prospective areas

- Analyzing air core, RAB, RC, and diamond core samples during the drilling phase as the samples come out of the ground

Ore Grade and Process Control

Vanta analyzers help mining companies maintain their profitability in many open-pit and underground mines and in their associated processing facilities. On-site labs generally take hours or days to provide results. With the Vanta handheld XRF, you can get the right answer well in advance of a laboratory result. In some mine-site situations, this can mean huge cost savings. Vanta analyzers enable mine geologists to engage in intelligent and accurate grade control and metallurgists to monitor the efficiency and fine- tune the beneficiation process in real time.

Vanta analyzers are pre-calibrated using a wide range of industry standard certified reference materials (CRMs) providing users with excellent out of the box accuracy. Simple, intuitive software features enable users to fine tune this factory calibration, where necessary, for optimal performance on different geological samples and matrices.

In ore grade and process control, Vanta handheld XRF analyzers provide measurable ROI through:

- Reduced reliance on mine-site labs by instant screening of open-pit blast hole samples

- Improved underground grade control when combined with appropriate sampling methodologies

- Analysis of stockpile material to aid blending and feeding of the mill

- Real-time analysis of feeds, precipitates, concentrates, and tailings for immediate adjustments in the processing plant

- Analysis of penalty elements in concentrates and Au bars

- Analysis of S and other elements to determine flux adjustments in samples

- Analysis of Si as a proxy for quartz to inform ball mill grind times and optimize recoveries

- Analysis of raffinates and various lean and rich liquid mixes in SX/EW operations

- Testing of liquid waste streams as part of hydromet processes, particularly in copper and precious metals plants

Environmental Monitoring and Remediation

Vanta handheld XRF analyzers are used to identify elements of interest in soil, sediment, dust, and tailings as part of typical environmental monitoring remediation processes in and around active and closed industrial properties. Some active operations are using handheld XRF analyzers to monitor SiO2 dust on processing equipment, Pb use in fire assay labs, and control Hg and As vapors in production environments in Au refineries. To help customers meet regulatory requirements, Vanta analyzers act as a fast and reliable screening tool that provide quantitative records of environmental monitoring that are easily archived.

Academic Research and Education

Portable XRF equipment, like Vanta analyzers, are playing an increasing role in academic studies relating to geological and environmental research projects and as a teaching tool. Vanta analyzers can aid in-house university laboratory methods, support undergraduate and post-graduate research projects, and facilitate teaching methods during routine coursework. The rapid results provided by Vanta handheld XRF analyzers can help educate students in modern analytical methods, aid in the identification of all types of samples, and provide a deeper understanding of mineral deposition and ore genesis relating to mineral deposit studies.

Durable and Reliable

Rugged

Mines and outdoor environments can be tough on electronic devices, often causing breakdowns that cost time and money. Vanta analyzers are durable for increased uptime and a low cost of ownership.

Vanta devices are drop tested and IP 65 rated dust and immersion resistant to protect against the hazards found in even the most challenging environments. They can withstand a temperature range of -10 °C to 50 °C (14 °F to 122 °F), so you achieve 100% uptime without waiting for your analyzer to cool, even in hot environments. The detector shutter on silicon drift detector models helps prevent punctures so you can analyze rough surfaces with confidence.

Revolutionary

Every circuit, contour, and interface of Vanta handhelds is engineered to be the best of its kind. Vanta analyzers incorporate Olympus’ new Axon technology, a breakthrough in XRF signal processing that delivers accurate and repeatable test results. Axon uses ultra-low-noise electronics enabling higher X-ray counts per second and faster results. Coupled with a new quad-core processor, Axon makes Vanta analyzers remarkably responsive, pushing the limits of performance so you get the best results in the least amount of time. Axon technology provides both test-to-test and instrument-to-instrument repeatability. Whether it’s your first test on your first analyzer or your thousandth test with your hundredth analyzer, Vanta handheld XRF gives you the same result every time.

Productive

Vanta analyzers maximize user throughput and make data archiving easy. Application-specific software features improve user productivity for fast return on investment.

- A new, intuitive interface enables the user to quickly navigate the device’s settings and software functions.

- The UI can be configured based on a customer’s specific needs. Users can customize what software features and functions are displayed on the main screen.

- Data are easily exported via a USB flash drive, Wi-Fi, or Bluetooth. Vanta analyzers are designed to enable powerful cloud applications.

- Vanta analyzers feature a clear, bright LCD touch screen that is readable in any light.

- Ergonomic buttons and an industrial-grade, push-button joystick enable users to easily navigate the system with gloved hands.

Olympus’ Vanta handheld XRF analyzer offers embedded GPS so users can pair results with precise GPS coordinates to document and map the location of elements. The optional 5-megapixel panoramic camera combines images of XRF data with GPS coordinates for inclusive archiving and streamlined reporting which provides unmatched data traceability to the field.

Vanta Analyzers for Mining

The VMR and VCR models are the Vanta analyzers typically used for mineral exploration. No matter the model, the rugged, fast, reliable Vanta analyzer features Olympus’ Axon technology, and is rated to pass a 4 foot drop test, and is rated to IP 65.

M Series

Our most powerful Vanta analyzers feature exceptional performance to handle the most demanding applications and lowest limits of detection (LODs). Each VMR model comes equipped with a sensitive large area silicon drift detector and a 50 kV X-ray tube with a rhodium (Rh) anode.

C Series

The C Series Vanta analyzers combine value with superior speed, limits of detection (LODs), and elemental range. Each VCR model is equipped with a silicon drift detector, a 40 kV X-ray tube, and an Rh anode.

Shock Resistant XRF Analyzer

Wanted a more rugged handheld XRF analyzer. Olympus responded with the Vanta – a tough, durable device designed to work in the most demanding conditions. Developed to be used in the tough environments of scrapyards, mines, refineries and manufacturing facilities. Vanta analyzers are built to perform in the harshest conditions for greater uptime and lower cost of ownership.

Vanta analyzers are built to pass a 4-foot drop test using a US Department of Defense method, so the occasional accident shouldn’t put your analyzer out of service.

For additional protection, Vanta analyzers are IP65-rated. This means that the analyzer is dust-tight and water resistant. With these features, you can confidently use your analyzer in even the most challenging environments. In addition to protection against rain and dust, Vanta analyzers are meant to work in both hot and cold environments. The instrument is made to perform in a temperature range of -10 degrees Celsius, to 50 degrees Celsius at full duty cycle.

When testing sharp materials, the detector shutters on CNM series models helps to prevent punctures, so you can analyze rough surfaces with confidence. Vanta analyzers combine durability with ease of use. The analyzers feature a large, responsive touchscreen that makes it simple to control the instrument and change settings.

The touchscreen is chemically treated to resist cracking and breakage, and is readable in any light so screen images are clear and bright when working outdoors. Some user will operate the analyzer while wearing gloves. The ergonomic rubberized buttons and the convenient joystick make it simple for users to control the analyzer with gloved hands.

Vanta handheld XRF analyzers are built with a durable and rugged design so that users get maximum uptime and productivity and avoid costly repairs. No matter the conditions, the Vanta is up to the challenge.

We built Vanta because there were a lot of things we knew we could do better. Vanta can really be described in 3 simple words: rugged, revolutionary and productive. It’s really the combination of features that we packaged into the Vanta that makes it unique.

We heard the factory folks who were building the Deltas; we heard what the service folks had to say. We heard what the application engineers were saying, and most importantly we were listening or caring about what the customers were saying.

We take customer feedback very, very seriously in the design of our products. So we’ve taken this feedback over many years of experience and fed that into the development of Vanta. We wanted to make a rugged device to improve the uptime of our customers, to make sure that it’s operational every time they pick up the instrument.

When we say the Vanta is rugged, we’re really talking about how it’s uniquely rugged. We’re the only XRF analyzer that passes the military standard 810-G 4 foot drop test. We’re the only one that is IP 64-65 rated. We’re the only one that goes from -10 to 50 degrees C at a continuous duty cycle, so that you can work all day in the hottest environments. And we have a detector shutter as well.

We provided a revolutionary design to allow our customers to make better decisions in the field. This is embodied by our Axon technology which gives us faster results, more reliable results. And the Axon technology is a series of signal processes enhancements that we’ve done. Really built around our detector and signal processing account. We’ve been able to do that with outstanding resolution and much higher throughput than we had before. And that throughput makes us more precise, it means faster test for the end-user as well as better precision.

We’ve also made the analyzers more productive and intuitive in their operation. We also embed applications in there to make them more productive, such as grade match messaging.

So one of the features that we have enabled in the Vanta is the ability to manage the fleet. The customer could have 4-5 Vantas and they’d like to configure all the 4 Vantas in a similar way.

In addition to having one set of good analyzers, you can put different setups on the same analyzer. If you’re an inspection company you can make one for one customer and if your other customer wants to have the data look a little bit different, you can set up another one for a different customer.

Over the course of the last 6 years since the Delta came out, technology has moved forward a long way. I mean, think about your cellphones. They can do a lot more now than they used to then. And we want to be able to take advantage of that kind of technology.

We wanted to build a user interface which was simple, which was intuitive, which was elegant. What we went about was first to understand how the iPhone or the Android and how the Windows phone solved some of the standard user interface problems.

The user experience to the Vanta is really keyed in on the large, bright screen that we have. And then using that, and using color as an accent to make sure that things that are supposed to stand out do, so that the information is clearly readable at a glance. And anybody who knows how to run a phone should be able to learn how to run a Vanta analyzer in seconds.

The greatest strength is putting the power of an analytical laboratory in the palm of a user’s hands. This allows you to take action directly at the site where you need the results.

I think one of the most important things is going to be our ability to have Wi-Fi with the analyzers so you can connect directly with the cloud.

It’s really everything that our customers have been demanding for years, which is the ruggedness, which is the productivity, which is the ease of use, which is the power of the product.

They’re going to see how quickly and how accurately they’re getting the results that they want.

Rugged, revolutionary and productive. These are simple terms that define the value that Vanta analyzers give our customers. Providing maximum uptime for a faster return on investment and lower cost of ownership. Analytical superiority for making better and faster decisions in the field. And a user experience that enables more efficient and productive operators. That’s the power of Vanta analyzers.

The latest generation of Olympus handheld X-ray fluorescence analyzers. Vanta analyzers are rugged, revolutionary and productive. They deliver the right answer in the toughest working conditions for maximum up-time and a low cost of ownership.

Vanta analyzers provide accurate elemental analysis and quantification for a wide variety of materials in as little as 1-2 seconds. Combined with a revolutionary new Axon technology that powers the analyzers, results are faster, more accurate and more reliable than ever.

Vanta is the toughest handheld XRF analyzer ever made by Olympus. It is designed to be used all day in the harshest conditions. Vanta analyzers are built to pass a 4-foot drop test. While we don’t recommend dropping the analyzer, an occasional mistake shouldn’t put you out of business. For additional protection the Vanta is IP 65-rated for resistance to dust and water.

When testing hot materials and working in hot environments, Vanta can test at full duty cycle from -10 degrees Celsius up to 50 degrees Celsius with the optional fan installed. The built-in shutter detector on C-series and M-series models helps protect the X-ray detector from damage and costly repairs, so users can analyze sharp samples with confidence.

Vanta analyzers are available in a variety of different models, optimized for your application. Choose an analyzer with either rhodium, tungsten or silver anodes depending on your analytical needs. Every Vanta is powered by Olympus’s revolutionary new Axon Technology for higher X-ray counts per second and fast results.

The analyzer software automatically corrects for temperature and air pressure, and resets the energy scale for every test for accuracy. Vanta’s responsive touch screen delivered vivid images that are clear and readable in any light. The analyzer’s user interface is simple to navigate, swipe, flick and tap just like on a smartphone. Three favorite buttons can be configured for quick access to your most frequently used settings. For operators wearing gloves, the Vanta’s joystick enables a user to navigate the interface without touching the screen.

An optional 5-megapixel panoramic camera and an in-line aiming camera record images of each test for comprehensive record keeping. Users can hot swap batteries for maximum uptime and productivity. Vanta analyzers have measurement windows that can be easily replaced without using tools. Test results are stored on an easily accessible removable SD card. The USB interface port enables direct downloads or seamless control of your analyzers from your PC. Optional Wi-Fi and Bluetooth adaptors make it easy to stream data in real time, simplifying data output.

Every Vanta comes with a docking station that charges the analyzer’s battery as well as the spare battery. Vanta analyzers combine durability, power and ease of use for excellence in a variety of applications including alloy and metal sorting, positive material identification, mining, environmental assessment, consumer product safety and more.

https://www.youtube.com/watch?v=vP9hjpNh9yc

The geoscience community are using the XRFs quite simply to save time and money. Getting that result in the field, being able to make a decision.

Over the past few years we’ve seen the uptake of our portable X-ray fluorescence analyzers in lab and downstream applications. Companies have realized that this technology is fast, reliable and very cost-effective.

My geologist is making multi-million-dollar decisions every day. He needs the most accurate, most precise instrument that he can buy.

Having worked in a mining environment on a drillery before, dusty, dirty, oily, terrible conditions. Very hazardous for people and for equipment. Having the Vanta being able to be dropped from a 4-foot height and still survive is a great feature.

The Delta was already the most rugged analyzer on the market and the Vanta just takes ruggedness to a really new level.

Downtime can mean hundreds of thousands of dollars or a week or two without an analyzer.

By making it more rugged and preventing the number of times you’re going to have a service event either through the analyzer being dropped and having to send it in, or through a detector puncher or dust, or water really means that over time you’re going to reduce the overall cost of ownership from eliminating and minimizing those service events.

An analyzer that’s IP 64-65 rated, that’s drop tested to US military standards, that has a shutter protector, all these features I want to have a geo standing next to a rig.

What we’ve done with this analyzer is really reimagine how handheld XRF is designed. So it’s not just an improvement on an older model, it’s a totally reimagined design. We did that with feedback from the customer, especially in the mining industry.

We showed the Vanta at a conference recently and the feedback from our customers about the modernization of our user interface with the Linux operating system, the smartphone swipe features, the accuracy of the instrument and the speed with which you were getting results was amazing. The feedback we’re getting from customers on Wi-Fi is excellent. Being able to download your data really fast and then send it into your own database.

You can easily just connect your Wi-Fi network and quickly tap the screen to update the software. You can have someone remotely log in and help you assess what’s going on with your analyzer. So to move our instrument unto that platform just makes it a lot more modern and that should reduce the amount of training time that’s needed to train operators on this instrument.

Having the Vanta with its new Axon Technology, with faster testing times, more precise and accurate measurements, an operator will be able to get through more tests, more times during the day leading to greater productivity and cost savings.

We’ve seen a lot of work in the laboratory of late, and I think that’s somewhere that the Vanta will really excel with the Axon technology, the great stability, precision, accuracy that that’s going to give us will largely eliminate any variability between analyzers that are coming out of their factory.

The fleet management aspect of the analyzer is really interesting in that you can set up all your analyzers to be exactly the same.

For customers to be able to say ‘This instrument is performing the same today as it will in 6 months, as it will in 12 months’ and their second instrument, their third instrument, their fourth instrument performed in exactly the same way.

Now the built-in GPS, the ability to pinpoint where you are exactly in the mine, we can now really sell to customers the ability to map blast holes.

We’ve got customers in Northern Finland trying to operate in sub-zero temperatures, and we’ve got customers in the [inaudible 04:09] in iron ore mines operating in a new limit, 50 degrees Celsius.

So, in these hot, nasty environments, the operator has the confidence that the Vanta will be able to remain stable, accurate and precise throughout the day.

As a geologist I need to know when the stratigraphy changes. I need to know if copper is going to go above an anomalous concentration so I can instruct the rig to keep going, to stop. Our focus has been supplying an analyzer to a mine geologist who is making multi-million-dollar decisions. We need to get that person the most accurate, the most precise analyzer so that every single decision he makes he can rely on.

Because the Vanta is faster, more reliable and more accurate, these labs will now be able to provide their customers and themselves with a greater return on investment.

I’ve worked with portable XRF in the mining and mineral exploration field for the last 15 years. The wish list is simple: it’s ruggedness, its reliability, its accuracy, precision and configurability flexibility. And I truly believe we’ve achieved this at Olympus with the Vanta.

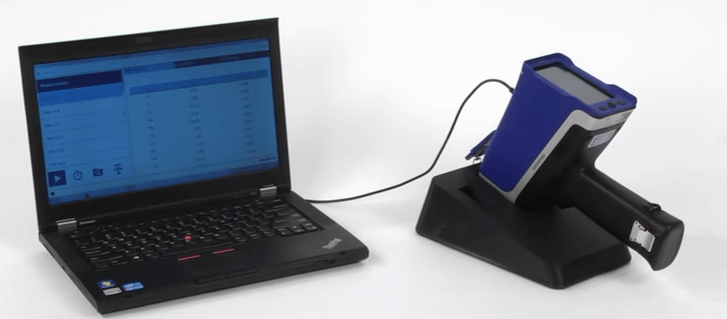

When you first open the case you’ll find your Vanta analyzer, the AC power adaptor, a USB cable, two lithium-ion batteries, 10 extra Kapton or Prolene windows depending on the model, a USB drive with product documentation and Vanta desktop software, a micro SD card that is already installed in your analyzer micro SD port and the Vanta analyzer docking station.

On the top of the analyzer, the data port cover protects the Vanta data ports and connections. To open the cover lift the ring and turn it counterclockwise until the cover releases. From here you can access the analyzer micro-SD port, the AC adaptor socket, two standard USB connectors and one mini-USB connector.

To use the analyzer, insert one of the fully charged batteries. The battery is keyed to fit in only one direction. If the battery won’t easily go in, take it out, rotate it and try it again. When the battery is inserted correctly, the hinge latches at both sides of the handle lock into place with an audible click. Every Vanta comes with an AC adaptor; this can be used to power the analyzer with or without a battery installed in the handle. The AC adaptor can also power the docking station to recharge the battery installed in the Vanta and the spare battery in the docking station auxiliary socket.

To power the Vanta docking station, plug the AC adaptor into the back of the docking station. Place the spare battery in the auxiliary socket. Press the power button on the back of the analyzer to turn it on. The Vanta welcome screen appears. Make sure to read the radiation safety warning. After you’ve read the radiation safety warning, log in. Tap the left-most box to display the keypad and enter the password.

Below the touchscreen are 3 buttons: two of these buttons are used to control the user interface. These buttons are useful when conditions prevent you from touching the screen, like when you’re wearing gloves. The left-most button is the back button. Press this to return to the previous data field in the UI. The center button is the joystick. The joystick moves in four directions: up, down, left and right. When pressed, the joystick functions as an enter button. The power button is on the far right.

Let’s discuss proper use of your Vanta XRF analyzer. Before using your analyzer, please review the user manual. Our instruments are safe and dependable when used correctly, so it’s important to thoroughly review the user manual to ensure best practices so that you and everyone around you will be safe.

When the red light is flashing, X-rays are being emitted. Never point the analyzer at yourself. Never point the analyzer at anyone else. Never place your hand over or near the analyzer window. When you’re ready to perform a test, place your sample on a stable surface. To start a test, tap the start button on the screen or pull the trigger. To stop a test, tap the stop button or pull the trigger again. Some users utilize the dead man trigger where the trigger must be pulled for the entire duration of the test. Releasing the trigger stops the test. To activate the dead man trigger pull down the menu bar and open the safety screen.

All Vanta analyzers feature hot swap batteries, so you can change batteries without powering down the analyzer. To swap out the battery, remove the spent battery and then insert a fresh one. A countdown screen shows you the power left in the analyzer so you know how much time you have to complete the swap. When you are done using your analyzer, press and hold the power button for one second. In the dialogue box that appears, tap ok to power off the analyzer. Place your Vanta in the docking station when not in use for safe storage.

Vanta analyzers feature simple measurement window replacement without the need for any tools. To change the cap on a proline measurement window turn off the Vanta and then firmly push the release button on the bottom of the snout. Pull the face plate down slightly from the bottom to release the top of the face plate from the snout assembly. The face plate swings down to expose the measurement window. Pull the old window off and replace it with a new one. Rotate the face plate upward and push in until it clicks into place.

To avoid expensive repairs, be careful not to touch the inside of the analyzer or allow dirt or other objects into the analyzer.

This video will introduce you to the software that powers the Olympus Vanta handheld XRF analyzer. Vanta analyzers are controlled through an easy to use interface. When the analyzer powers on, the welcome screen will appear. Here you will be prompted to enter a password. Tapping the left-most box brings out the keypad. Enter your password using the touchscreen. The live view screen will load. From the live view screen, you can navigate to different functions, initiate a test or view test results. The responsive touchscreen makes it easy to operate the UI with gestures similar to those on a smartphone. Flicking up or down causes the screen to scroll in that direction. Swipe right to display the next screen and view recent test results, or left to go back to the previous screen.

There are two types of buttons in the user interface. Action and New Screen. Action buttons have a dark blue rectangular background. When pressed, they cause an action to occur. New screen buttons have a light blue or white rectangular background. Pressing one of these causes a new screen to open. Tap a button to activate it. Tap and hold any button to display its name.

To initiate a test, tap the start button on the lower left-hand corner of the screen. When the test is complete, the results are displayed in the center of the screen. To view notes, spectrum or camera images, tap the plus sign to expand these menus. To collapse an open menu, press the minus sign. Next to the start button, are three customizable favorites buttons. During instrument setup, users can select which functions they want to appear in the favorites buttons.

At the bottom of the screen is a status bar that displays the status of the hardware as well as system messages. At the top of the screen is the menu bar. Swipe down on the left side of the bar to view the system tray. The tray displays buttons that allow you to control the hardware or view the hardware status. From here you can access Bluetooth, Wi-Fi and the GPS for easy and efficient use. Swipe down on the right side to view the menu tray which displays buttons that enable you to select an analysis method and set test parameters.

If your Vanta is equipped with a camera, swipe left to view the live camera image. You can also connect your analyzer to a PC with the Vanta desktop software. Once connected to a PC you can view test results, change user and device profiles, change the password and more. With these basics in mind, you’ll be able to expertly navigate the Olympus Vanta’s software for easy and efficient use.

https://www.youtube.com/watch?v=QLmTVc45Txc

M: Our segment this week is a Tech Corner that was recorded when we had an in-house webinar with Olympus on their Vanta handheld XRF XRD analyzers. While they were here doing the webinar, we said hey, you’re here, you’ve got your equipment: let’s do a Tech coner. And so here it is, here’s our Tech Corner with Diane Hillhouse of Olympus, showing us the Vanta handheld XRF XRD analyzer. We have in the studio with us today Diane Hillhouse of Olympus. And Diane, you’re going to be showing us an XRF analyzer, right?

D: Right.

M: What in the world is an XRF analyzer?

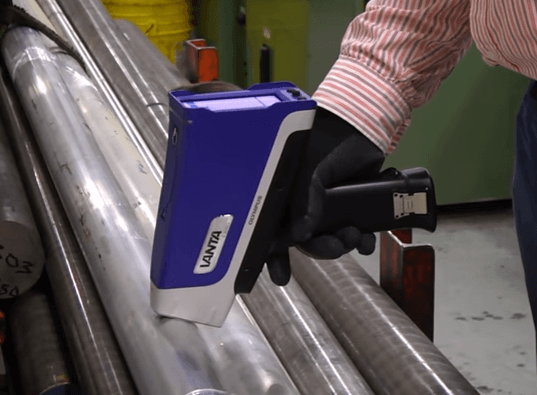

D: So, this is what one looks like. This is Olympus’s newest XRF analyzer, the Vanta. And so XRF stands for X-ray fluorescence and this is also known as a PMI analyzer or a PMI gun and it’s used for positive material identification of metals and allows in fabrication or a plant maintenance setting.

M: Okay, and you said X-ray. So does this literally shoot X-rays out the front like a little ray gun or something?

D: It does, but it’s very low-level X-ray so it’s very safe. And the way it works is we produce X-rays through an X-ray tube right here so when I pull the trigger, I’m sending very low-level X-rays into the sample, but enough energy to excite the sample and enough that the sample itself will send back its own characteristic X-rays. And then the analyzer takes these characteristic X-rays and determines what element on the period table or elements on the periodic table are in the sample and it determines the concentration. And it can do this on metals and alloys, it can do this in plastics, in glass, in soil sediment.

M: Ok, so it’s not just metals then. I was always kind of under the impression these things are basically metal. But you’re saying a wider array of elements.

D: Right. Metals and alloys is the most common application or common usage, but we can take a look at elements and pretty much any type of sample, as long as there’s enough of that element that the analyzer can detect it.

M: Ok, I know this is obviously a handheld unit, so I’m assuming it’s portable and you’re going to take it into the field, you’re going to take it on the shop floor. I know it’s a precision instrument, so is it rugged?

D: Absolutely. The Vanta is very rugged and that’s the number one request from customers. I mean, they’ve been around for a while and again it’s like a laboratory unit in your hand so the next phase was can we have a rugged unit? That’s what everybody’s been asking for. And the Vanta, we put it through some very – I mean, in addition to the design, we put it through very rigorous testing protocols. One of them is a US Department of Defense military standard 10G 4-foot drop test, and again we’re not encouraging anybody to drop an instrument. But in this type of environment, like the foundry, steel mills, petrochemical refineries.

M: They get banged around, yeah,

D: They’re going to get banged around, they’re going to get occasionally dropped; hopefully not dropped a lot but it does happen. So, if it gets dropped, hopefully you’ll be able to keep on going.

M: What’s the IP rating on this?

D: There’s an IP 65 rating that protects it against high velocity water and dust. What I was also going to mention earlier in that fielder testing that we did, we also tested all the moving parts, anything that might be broken during usage and for example the trigger was tested over 1.5 million times, which is more than you’ll ever pull the trigger.

M: My finger will probably wear out before the trigger.

D: We wanted to make sure.

M: So all the moving parts are tested extensively.

D: Exactly.

M: Ok. So, it seems to me, we mentioned earlier this is a precision instrument. You told me that before the show. And now you just said it’s rugged. Seems to me those are kind of at odds with each other; how do you guarantee or make sure that the accuracy is there even after this unit’s been banged around as we just said it can be.

D: Right. That’s the balance, right? And it’s the most important part of the instrument. Obviously you do your job every day, it has to be accurate and precise and then the ruggedness is a bonus. It really helps with the cost of ownership. But in order to do that you have to have a very stable instrument, so in the Vanta we’ve incorporated a couple of things. We are using very ultra-low noise electronics coupled with a new quad core processor, it’s called our Axon Technology.

M: Quad core, very fast processor.

D: Very fast. So those coupled together give you the lowest detection limits on elements, it gives you the fastest answer, it gives you the best repeatability and then it gives you the best reproducibility over different instruments.

M: Ok. Show us how it works.

D: Sure.

M: So if we can switch over to the gauge cam here guys. Excellent.

D: So we’re going to test.

M: This looks like an extruded bar that you just put this down on. It looks like just your basic, like a smartphone screen.

D: It is. That’s another thing with the Vanta, we designed it in an environment everybody’s used to – your smartphone where you’re swiping from reading to reading, or up and down. Your most used operations are down here on your Favorites tray; if they’re not in your Favorites tray then they’re no more than two swipes, two buttons away. So we’re going to…

M: So you’re just going to pull the trigger there. Alright. So I noticed you put this right down on the sample.

D: As close as you can.

M: Ok. There we go. Now, this comes back with a written – I notice here at the top, is that actually telling me what this alloy actually is?

D: It is. So we talked about the analyzer obtaining a chemistry from a sample, getting the element of interest and then the concentration of that element. And then the next thing it does is it tries to match it against a library of known alloys. We have the industry standards for over 750 alloys in the analyzer. They’re most commonly used in the maintenance and manufacturing markets, although it is customizable. So what we’re trying to do is we’re trying to match the chemistry to an industry spec and you can see we have a nice graphical display, it’s color-coded. If you’re in the green, you’re definitely in the industry spec for that element. If you’re in the yellow, you’re within spec within the margin of error. And then if you’re in red, you’re out of spec. And you can see this like the chrome is right on the edge there.

M: So if you were taking multiple samples and you have a lot of shipping comes in from a vendor and you’re measuring multiple samples, and you see that the reliably showing that they’re really on the edge in this case for the Chromium, that might indicate you want to do further testing, more extensive testing on your part or just contact the manufacturer and say ‘Hey, I’m consistently reading kind of a low end on the chromium, right?’

D: Right. Your quality manager in a manufacturing situation or your reliability manager out in the plant, they’re going to have protocols for things like that. I mean, you use the analyzer to verify the chemistry against a mill test report or an MTR, you want to make sure your supplier has sent you what you asked for and what they said they sent you. Out on the plant you want to make sure that your supplier sent you the right component before you install it.

M: So it’s a good quality control tool. Now, I noticed obviously I am assuming all this data obviously is being stored within the unit. So, somebody goes out in the shop floor, out in the field, they take a bunch of measurements, all that data is stored in here. What happens with that data?

D: I’m glad you asked. Data management is extremely important in manufacturing and maintenance situations. You know, when you invest in one of these analyzers it’s not normally just to pull the trigger and see what the answer is. I mean, it’s about archiving that data and having a historical record. It’s traceability, it’s creating report.

M: Or maybe just even further analysis.

D: Right, it’s all these things. So, the Vanta actually has several ways to easily download and export this data. And I’m going to show you our IO port here. So it has several different ways, pretty much any way that you want to download the data, any situation you’re in, you can download it via Wi-Fi or Bluetooth. There’s a flash drive. You can directly connect it to a computer. There’s an SD card. So you should be able to get the data off this very easily.

M: Pretty much any way you want, yeah.

D: And in additionally to doing it that way, it’s also cloud-enabled. Which is obviously used more now and it’s definitely the way of the future.

M: So, you could upload your data, program this to upload your data directly to wherever. And it doesn’t necessarily have to be Olympus, a third-party cloud service, whatever?

D: Right. Olympus has its own cloud site where you can securely store and access data. You can use a third-party cloud site…

M: Maybe even a network drive or something like that as well.

D: Exactly, exactly. So, it’s not just for data, but then you can use it for your fleet management, you can use it – that’s where you’re going to get your software upgrades, your firmware upgrades, your library upgrades. So, there are many, many possibilities.

M: And it looks like very simple to use, an operator can be trained on this very quick.

D: Absolutely. The user interface that we talked about earlier, that’s one of the nice things about it because it is an environment, the modern user interface that everybody is used to, it’s very easy to train on. If you use the analyzer every single day or you only use once a month, it’s very easy to get your proficiency on par to where it needs to be, no matter how often you use it. It’s very, very easy to use.

M: Alright, perfect. This was the Vanta XRF analyzer. Diane, thanks for joining us in the studio this morning. If you want more information on the Vanta XRF, there is a link underneath the player page, click on that, that will take you to the XRF, the Vanta page on the Olympus site and you can read more about it. Diane, thanks a lot!