Oh, please tell me what is metallurgy? There is no better way of paying tribute to the memory of a scientist than by developing and carrying forward those ideas which he has contributed to science and which are for us the very essence of his immortality. For a lecturer who has not had the great privilege of studying under Professor Howe or even of knowing him in person, these ideas must be transmitted through the printed word. It is our great good fortune that Professor Howe left to us a rich heritage of publication, not only in his classic monograph on the “Metallography of Steel and Cast Iron” but in a wealth of earlier books and papers in the transactions of this Institute and of other scientific and engineering bodies. An outstanding characteristic of this published record is the great breadth of interest and of vision which it portrays. His was not a narrow specialization in only the scientific aspects of ferrous metallography. Oil the contrary many of his important contributions had to do with a far broader field of metallurgical endeavor. He insisted that his students be well grounded in the fundamentals underlying the whole field and not led into the narrow groove of specific applications. Among his first major publications we find papers on copper smelting, extraction of nickel, the efficiency of fans and blowers, thermic curves of blast furnaces, the cost of coke, and the manufacture of steel. These are the papers of a metallurgical engineer and it was among engineers that Henry Marion Howe made his early and well-merited reputation.

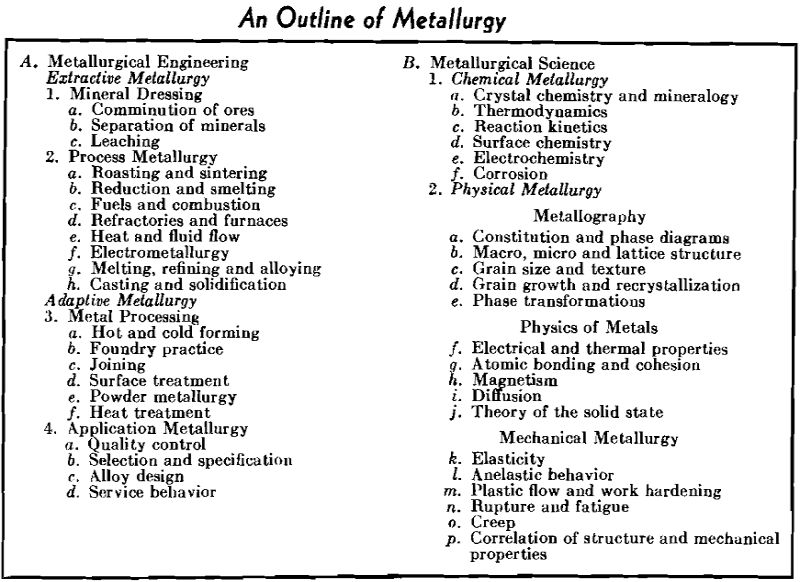

Metallurgical Engineering

Metallurgical engineering is the direct descendant of that ancient art first brought to man by the titan demigod Prometheus. He it was who dared oppose the will of newly-crowned Zeus when that cruel monarch planned to sweep mankind off from the world and plant a newer race there. He stole fire from heaven and brought it down to earth for men to use. He taught men the motions of the stars and devised for them numbers and letters.

Mineral Dressing

Metallurgical engineering begins with what is “hid underground,” the ore, thus illustrating a constantly recurring phenomenon, that the metallurgist is intimately concerned with nonmetals. Metallurgy must in practice begin with the ore and its first operations are those of mineral dressing. Here it is very closely allied to such fields as solid fuels, ceramics and nonmetallic minerals and like them it is here intimately associated with economic geology and mining. In brief this first segment of metallurgy constitutes also a portion of a broad field which is quite properly termed mineral engineering. Much of the scientific background lies in the fields of crystal chemistry, surface chemistry, mineralogy, hydrodynamics and other branches of knowledge not too familiar to most metallurgists but indicative of the breadth of the field.

Process metallurgy has a long and honorable history too familiar to most metallurgists to require discussion. This is the very stuff on which the Iron and Steel Division is made. It is the succession of steps or processes by which impure mineral is reduced to metal, refined, alloyed and delivered according to a specification. It is an old art, but with the aid of chemical science it has become a chief part of modern metallurgical engineering. It is closely akin to chemical engineering with which it has many ideas and problems in common. The study of the field in terms of processes rather than by metals here follows the lead of chemical engineering education with its emphasis on the “unit processes.”

The more physical aspects of production metallurgy, the methods of forming into useful shapes, are grouped in the outline under Metal Processing. Among these we note the overlapping of metallurgy with recognized trades or professions such as welding, founding, forging, electroplating. These fields are as much parts of metallurgical engineering as are steelmaking or heat treatment, and they deserve as much interest and recognition on the part of the metallurgical profession. For too long a time they have been relegated by metallurgists to rule-of-thumb control. Much can be accomplished here by the application of science and of sound engineering as witness recent advances in welding and the current renaissance in the foundry industry. Here we have seen in recent years the doubling of the strength of gray iron by persuading the graphite to form nodules rather than flakes. We have seen more than the doubling of the dependability of steel castings through control of soundness.

Application Metallurgy

The task of putting the right metal in the right spot with full regard for cost and service is an important part of metallurgical engineering. The selection and specification of metals and of their heat treatment is often a task of large proportions involving all the skill and understanding of an experienced metallurgist. The more complex the structure, the more kinds of metals must he taken into consideration; the greater the quantity of production, the more urgent it becomes to select for each part the right alloy, the right quality, for economic manufacture and service. It is in this field particularly that the science of physical metallurgy finds its practical engineering applications, and that metallurgy becomes the servant of all engineering. The metallurgist is constantly working with and for engineers of different backgrounds. He must know their language. He must understand t he rudiments of design, of stresses and vibration, of fabrication and inspection and assembly. His success is gauged by his ability to serve his fellowman in adapting the right metal for each use

Physical Metallurgy

Physical metallurgy is the science of the metallic state. Offspring of physics and physical chemistry, it is intimately concerned with the structure of metals and alloys and with the phenomena which occur within this structure. The study of metal structures and of the processes which determine them is called metallography. It is regrettable that this term has become widely used to connote only the microscopic observation of structure. Its real significance is far wider. In its broad sense it, signifies the whole science of metal structure. This includes all knowledge of equilibrium in metallic systems as shown in the many phase diagrams that have been published and the nearly infinite number which remain to be studied. It includes recrystallization and grain growth and precipitation within metallic phases.

The whole complex series of changes, by which soft austenite is converted into tough bainite or hard martensite and the latter is tempered to produce structures of desired properties, is a part of this science of metallography. It was in this broad sense that Professor Howe used the word in his “Metallography of Steel and Cast Iron,” and I urge that we return to this usage.

It is far more important that the student have a real grasp of physical chemistry than that he know the dimensions of the biggest blast furnace or the latest wrinkle in instrumentation. It is far more important that he understand what goes on inside a piece of steel during heat treatment than that he be able to distinguish between bainite and fine pearlite under the microscope. It is far more important that he be able to think than that he know the characteristics of a wide variety of alloys. And it is in the teaching of the fundamentals that the instructor has his best opportunity to help the student learn to think.