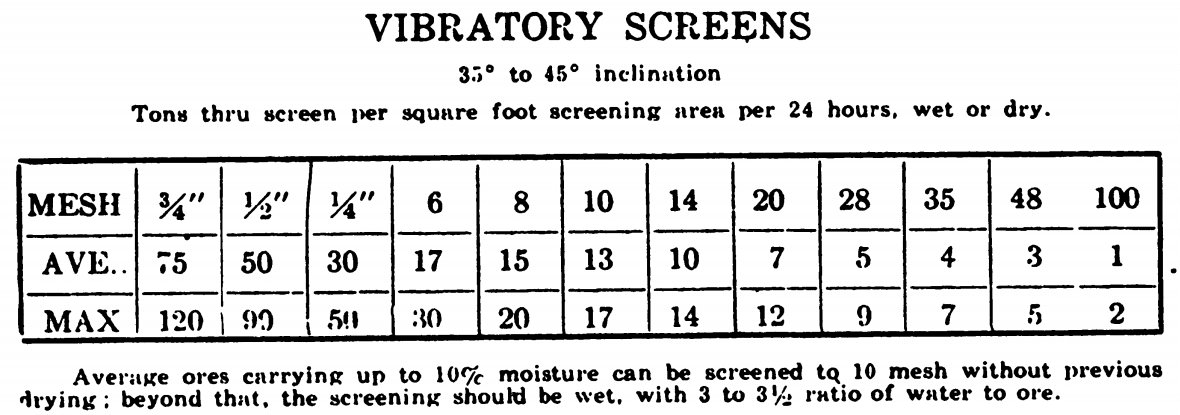

Average ores carrying up to 10% moisture can be screened to 10 mesh without previous drying: beyond that, the vibratory screening should be wet with 3 to 3.5 ratio of water to ore. Approximate Tons thru screen per square foot screening area per 24 hours, wet or dry.

moisture and screen efficiency

Screen Capacity of Crushing Plants

Screens are made of perforated steel plates or woven wires which form a mesh of square or rectangular openings between adjacent screen material. The three basic types of screens used for aggregate processing are known as:

- inclined vibrating screens,

- horizontal screens, and

- revolving screens.

The inclined vibrating screen is a slightly inclined flat screen. It is vibrated in a circular direction about an axis parallel to the plane of the screen. The circular motion is provided by eccentric parts on the drive shaft. This motion throws the material down the incline of the screen. Rubber mounts for the screen prevent vibration of the supporting frame.

The horizontal screen is a modern version of the shaker screen with improved effectiveness caused by higher speed motion and a shorter stroke. It is similar to the inclined vibrating screen but it requires less headroom. Since it is held in a horizontal position, this screen is not used for scalping.

The revolving screen is either a large drum with perforated plate sides or a wire mesh shaped to form a cylinder with almost a horizontal axis. The drum revolves slowly about the inclined, longitudinal axis. Material enters at the upper end of the cylinder and moves inside the screen drum until it either passes through the side openings or out the lower end. The sizes of openings may increase along the drum length. Or the screen may consist of concentric drums of increasing diameter to give various separations with one rotating screen unit.

The effective area used to find the capacity of a revolving screen is usually taken to be one-third of the diameter of the drum times the length. The quantity of material that can be handled by a screen during a given time depends on the inclination of the axis and the speed of rotation.

Frequently, the flat, vibratory screens are designed in combinations of parallel decks. When more capacity is needed for any screen, it can be obtained by using two or more screens in tandem to increase the total area and the capacity for each screen level. A portable plant may have two and a half decks or layers of screens at the beginning of the process to receive the feed. Parallel decks are separated by enough distance to allow the materials to move between decks. The material retained on the top deck goes to the primary crusher. Aggregate which passes through the top deck but is retained on the second deck goes to the reduction crusher. The output of both crushers is recirculated to the top deck for repeat screening. Finally, all the material that passes the second deck is ready for classification, and the excess sand is removed through the bottom half deck.

To prevent a screen from being clogged by sticky material, it may be desirable to heat the screen. This can be done by passing an electrical current through the wires of the mesh, heating them to perhaps 100 to 300°F. There is not much danger of the material clogging the screens of washing plants.