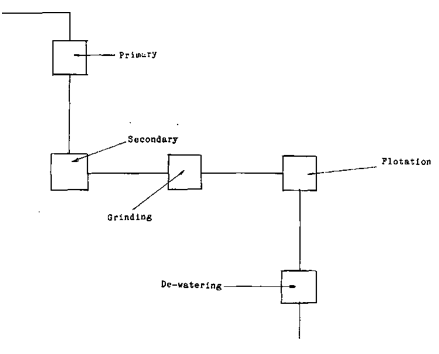

A flow-sheet is a schematic drawing that shows simply the order of processing. In the below example, the arrows indicate the direction that the ore is taking through the process. Some are very basic or conceptual, others are very detailed. Here is very basic.

Use a flowsheet for a properly done circuit check that will save you lots of work and by catching problems as they are developing save a lot of down time for the equipment.

Now that we know what a circuit flowsheet is, what do we need to check it?

In all mills there are areas that cause problems. This could be anything, spills, worn out parts and pieces or something restricting ore movement. Checking your equipment for anything that may cause damage, slow production, or cause needless

In all mills there are areas that cause problems. This could be anything, spills, worn out parts and pieces or something restricting ore movement. Checking your equipment for anything that may cause damage, slow production, or cause needless  work is doing a circuit check. You are checking the equipment to be sure that everything is running as it is supposed to, and that the wear that the moving ore causes is not becoming excessive in any one spot.

work is doing a circuit check. You are checking the equipment to be sure that everything is running as it is supposed to, and that the wear that the moving ore causes is not becoming excessive in any one spot.

As we cover each of the different circuits you will be learning where the standard trouble spots are and what the changeable factors are.

During every circuit check regardless of area, you will be monitoring bearing performance. Bearings are common to all circuits and may be a source of mystery to the mill-man. Because of this I felt that it would be appropriate to show you right at the start how bearings are chosen for their particular job and environment.