Table of Contents

Abstract

The U.S. Bureau of Mines has patented and transferred to industry an abrasive-enhanced water-jet rock drill. This drill incorporates three novel components: a collimator, jet deflectors for cutting clearance, and an unpressurized swivel, which rotates at 1,000 rpm while passing 20 gpm of an abrasive slurry flowing at 1,000 ft/s.

Drilling occurs through the action of a 10,000-psi, 20-gpm water jet into which is entrained 22 lb/min of abrasives. The pumps, hoses, and fittings are those commonly used in the water-jet-cleaning industry. Only inexpensive, common sandblasting abrasives are used.

This drill can cut through hard rocks with moderate-pressure jets; e.g., rocks with a compressive strength of 73,000 psi can be drilled with a 10,000-psi abrasive jet. In addition to drilling holes, the drill can cut deep, narrow kerfs; collar a hole at any angle; drill through rubble; and chamber holes.

The development of the abrasive jet drill is a significant advance in the state of the art of hard-rock drilling. The Government of the United States has licensed the abrasive jet drill patent to Weatherford Water Jetting Systems.

Introduction

Water-jet and mechanically assisted water-jet rock drills can be used for rock bolting and other mining construction applications. These drills have a number of advantages over rotary or percussive rock drills, including portability and the ability to collar a hole at any angle.

One disadvantage of water-jet drills is that pressures required to drill hard rock are approximately the same as the unconfined compressive strength of the rock. Thus, a 70,000-psi water jet would be needed to penetrate a rock with an unconfined compressive strength of 70,000 psi.

This disadvantage can be neutralized by incorporating abrasives into the cutting jet. The abrasives enhance the cutting ability of the jet so that relatively modest pressures can be used to cut very hard rock; e.g., a 10,000-psi abrasive jet can drill the Sioux Quartzite, which has an unconfined compressive strength of 73,000 psi.

Abrasive jets are in common use in cutting hard material (2-4), but heretofore, abrasive jets have not been used to drill deep holes or to cut deep kerfs in hard materials. There are many engineering applications where it is desirable to deep drill or kerf hard rock, including rock bolting or drilling for blasting. Kerfs are desirable in mining to prevent overbreak in blasting and to isolate ore from waste rock for selective extraction.

For deep drilling or kerfing, the jet must cut enough clearance for the drill pipe to follow into the hole. This, in turn, requires that the drill pipe be rotated. This requirement has been an impediment to the use of abrasive jets in drills or kerf cutters; therefore, given the state of the art, this means that a rotary coupler and a multiple-orifice nozzle would be needed to pass a pressurized abrasive slurry. This high-velocity slurry would cause rapid erosion leading to the destruction of the nozzle and the rotary coupler.

The U.S. Bureau of Mines has found a way to circumvent the problem of rapid erosion caused by high-velocity slurry by applying the components of a collimator, jet deflectors, and a nonpressurized swivel. These components were used together to form an abrasive water-jet rock drill. The development of the water-jet drill to enhance the efficiency of metal mining was done as part of the Bureau’s program to stimulate innovations in the U.S. mining industry.

Collimator

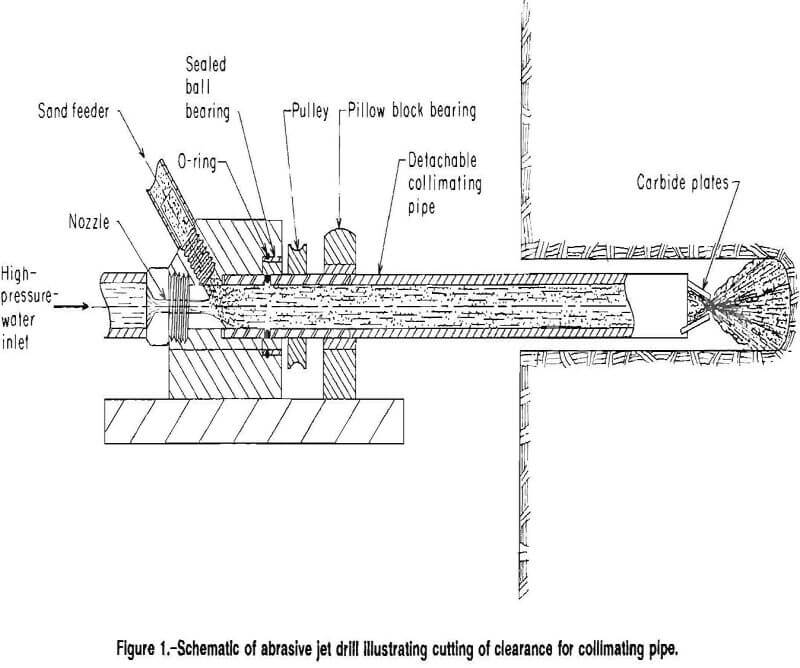

A water jet formed by the discharge of a nozzle into a pipe (fig. 1) will not dissipate. It will retain its cutting ability significantly beyond the distance at which jets passing through air are effective. The jet is constrained to flow parallel to the pipe axis; i.e., it is collimated. This colliinated flow reduces the rate of loss of momentum of the jet as compared with a water jet in air. A water jet in air loses its rock-cutting ability shortly after exiting the nozzle, whereas the collimated abrasive jet has drilled hard rock (a dolomite with a compressive strength of 20,000 psi) 5 ft from the nozzle. Experiments have shown that a collimated abrasive jet retains 75 pct of its energy after passing through a 10-ft length of collimating pipe.

In the abrasive jet drill, water from a 10,000-psi, 20-gpm pump is accelerated to 1,250 ft/s through a 0.080-in- diameter nozzle. The water then entrains sand and air, and the resultant slurry enters an ANSI schedule 160 steel pipe (the collimator). Lengths of pipe from 2 to 10 ft have been used as collimators. Abrasive particles are accelerated by the jet and retain most of their kinetic energy as they pass through the collimator. Sand particle velocities as high as 1,000 ft/s have been measured at the outlet of the collimating pipe by double-exposure, high-speed photography.

Since a collimating pipe situated downstream of a high-pressure nozzle permits a high-velocity jet to retain its cutting ability for several feet, the collimating pipe can serve as a drill rod. In the Bureau’s abrasive water-jet rock drill, the nozzle is situated several feet upstream of the end of the drill so that it never enters the drill hole. The drill stem downstream of the nozzle is not pressurized. This is in contrast to conventional water-jet drills, which use a multiple-pass nozzle situated at the bottom of the hole at the end of the string of pressurized pipe.

Jet Deflectors for Cutting Clearance

Drill pipes must be capable of following into a drill hole as the hole deepens. The drill must cut a hole wider than the outside diameter of the drill stem. Conventional water-jet drills accomplish this by using rotating, multiple-orifice nozzles at the downstream end of the drill string.

This arrangement has not proven practical for an abrasive jet drill because the multiple orifice is quickly destroyed by wear. Instead, with the Bureau’s drill, clearance is cut by deflecting the jet with two 1- by 0.25- by 0.125-in carbide plates silver soldered into slots at the end of the collimating pipe (fig. 1). These plates are positioned so that a portion of the jet is deflected and cuts wider than the pipe diameter, while the remainder of the jet passes undeviated between the deflectors and cuts the central portion of the drill hole.

The carbide deflectors are placed at an angle of 15° to the center plane of the collimator. This placement permits the abrasive jet to cut a hole wide enough for the collimating pipe to enter and deep enough to maintain a steady advance into the drill hole.

The deflection angle chosen is a compromise between the competing needs for axial and radial cutting. High angles of incidence of the abrasive onto the carbides engender wide, shallow cuts, while low angles of incidence give narrower and deeper cuts. Of course, the collimating pipe and the deflectors exhibit wear, but both the pipe and the plates are low-cost, expendable items. The wear process is such that both the pipe and the deflector plates are worn out after about 2 h of abrasive jetting at 10,000 psi, 20 gpm.

Nonpressurized Swivel for Passing Abrasive Streams

Present state of the art requires that the drill string of a water-jet drill be rotated in order to cut clearance. Rotation of a conventional water-jet drill requires that the pressurized water pass through a swivel. This swivel must contain high pressure (10,000 to 30,000 psi) while rotating at high speeds (500 to 2,000 rpm). Because of these requirements, the high-pressure swivels are apt to be expensive and unreliable.

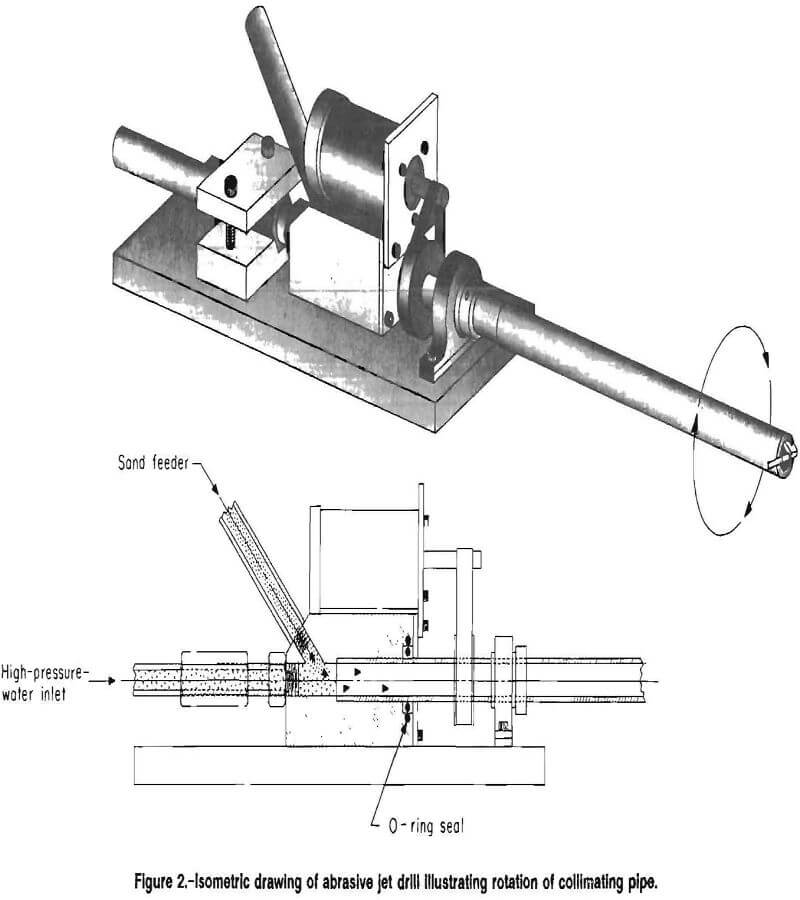

The Bureau’s abrasive jet drill avoids the problem of high-pressure swivels because the fluid in the collimating pipe downstream of the nozzle is not pressurized but exhibits a vacuum. The pipe is rotated inside a sealed ball bearing and a pillow block bearing (fig. 2). The rotary motion is imparted by a hydraulic motor coupled to the pipe by a chain and sprocket. The simple bearing swivel is very inexpensive ($8 in 1986).

Design of the Drill

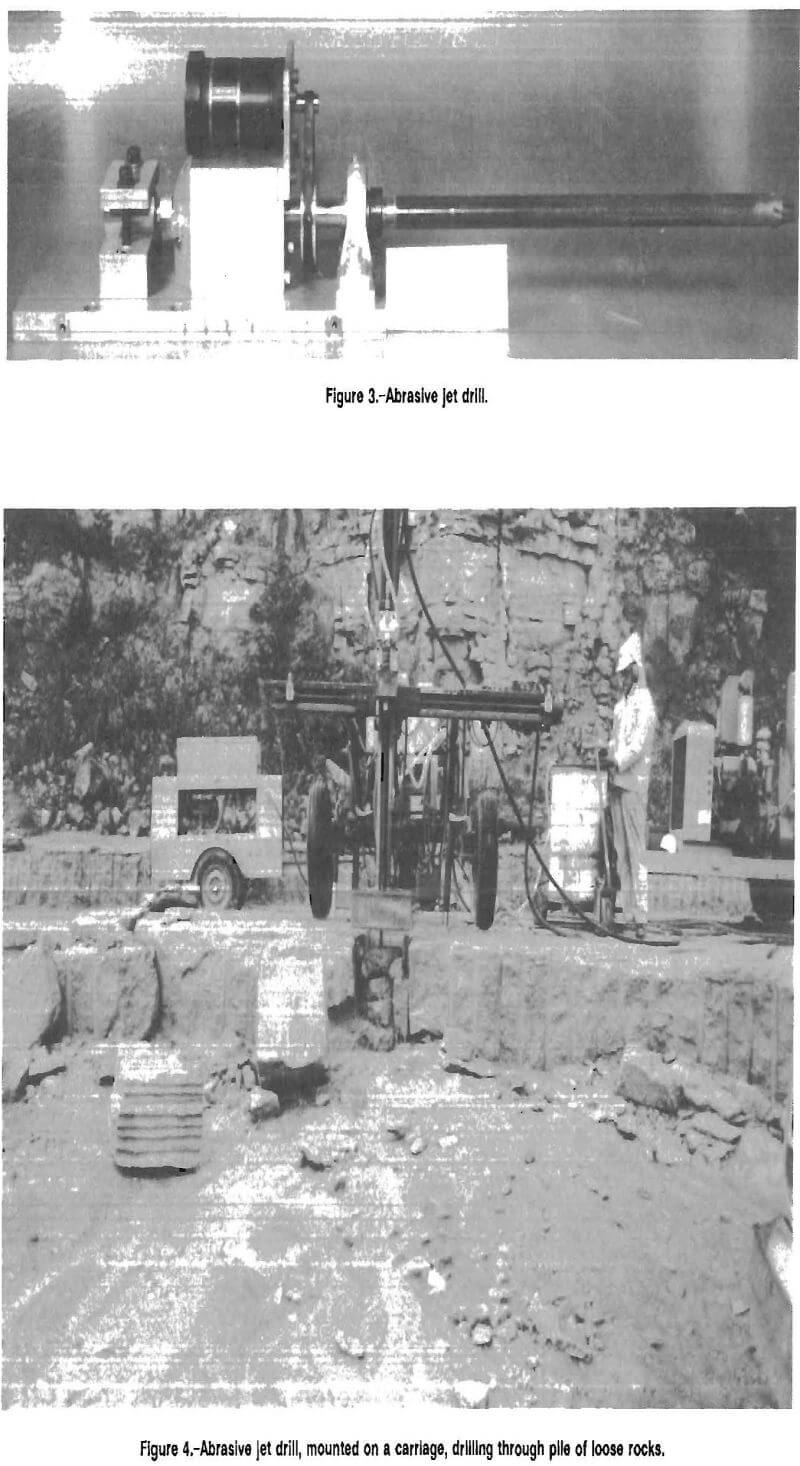

The drill, as described in the preceding sections, is essentially a rotating collimating pipe terminated by silicon carbide deflectors (figs. 2-3). The drilling apparatus is composed of these essential parts and has various means of activation and control.

Water (20 gpm) is pressurized (10,000 psi) by an Aquadyne model GE150 DT triplex pump and fed through water-blaster hoses to a 0.080-in-diameter 3D Leach and Walker nozzle. This nozzle has a 13° conical taper downstream from the incoming conduit and terminates in a straight section with a length equal to three outlet diameters.

The pressure is dropped across this nozzle as the jet discharges into a mixing chamber. The Venturi effect thus created entrains 22 lb/min of sand and air into the mixing section through hoses connected to a sand lance in a barrel. Sand, air, and water are mixed and flow at 1,000 ft/s through the collimating pipe.

The drill is carried on a carriage (fig. 4), upon which are mounted controls for the air and hydraulic systems. The drill is remotely controlled from an operator’s station.

The collimating pipe is rotated at 250 to 1,000 rpm by a motor coupled to the pipe by a chain and sprocket. The drill rides on two orthogonal screw-driven mounts, permitting the drill to be translated along the surface of the rock as well as to penetrate into the rock. This capability permits the drill to be used to cut kerfs as well as to drill holes.

Drilling

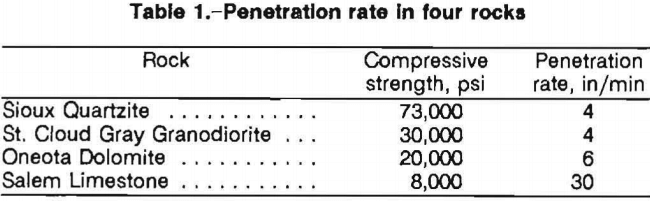

Test holes were drilled in samples of Sioux Quartzite, St. Cloud Gray Granodiorite, Oneota Dolomite, and Salem Limestone. Test data are given in table 1. These tests were conducted with a 10,000-psi, 20-gpm water jet, a rotational speed of 600 to 700 rpm, and an entrainment rate of 22 lb/min of dry sand. Deflectors were set at 15° to the axis of the pipe.

These test data show that hard rock can be drilled with an abrasive jet drill, but the penetration rate attainable varies with rock hardness. Table 1 gives the maximum penetration rate attained for each rock tested.

The Bureau’s abrasive-enhanced water-jet drill offers the following advantages over other rock drills. This drill—

- Can operate with a pressure that is far lower than that of conventional water-jet drills. The abrasive water-jet drill can cut hard rock with a compressive strength of 70,000 psi with 10,000-psi water pressure. Other water-jet drills must use a pressure approximately equal to the compressive strength of the rock. The abrasive-enhanced water-jet drill uses only commercially available hoses and fittings commonly used in the water-jet-cleaning industry.

- Does not physically contact the rock and, thus, does not have to absorb the force of the rock pushing back on the drill rod. This permits the drill to be built of much lighter materials than conventional drills.

- Does not require a bit.

- Can enlarge (chamber) selected parts of the drill hole by slowing the penetration rate. This capability would be helpful to mine operators who must blast tough rock. The chambers can be loaded with extra explosive to put increased rock-breaking power where it is most needed.

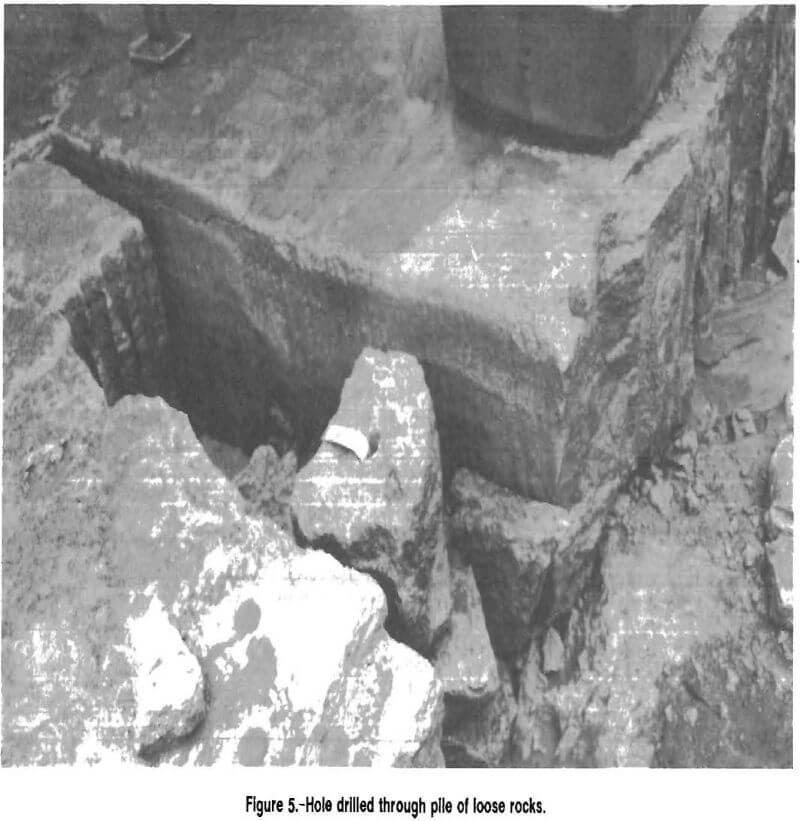

- Can penetrate uncompacted, loose rock (fig. 5). This ability could be used to drill probe holes or blastholes in gob areas of mines.

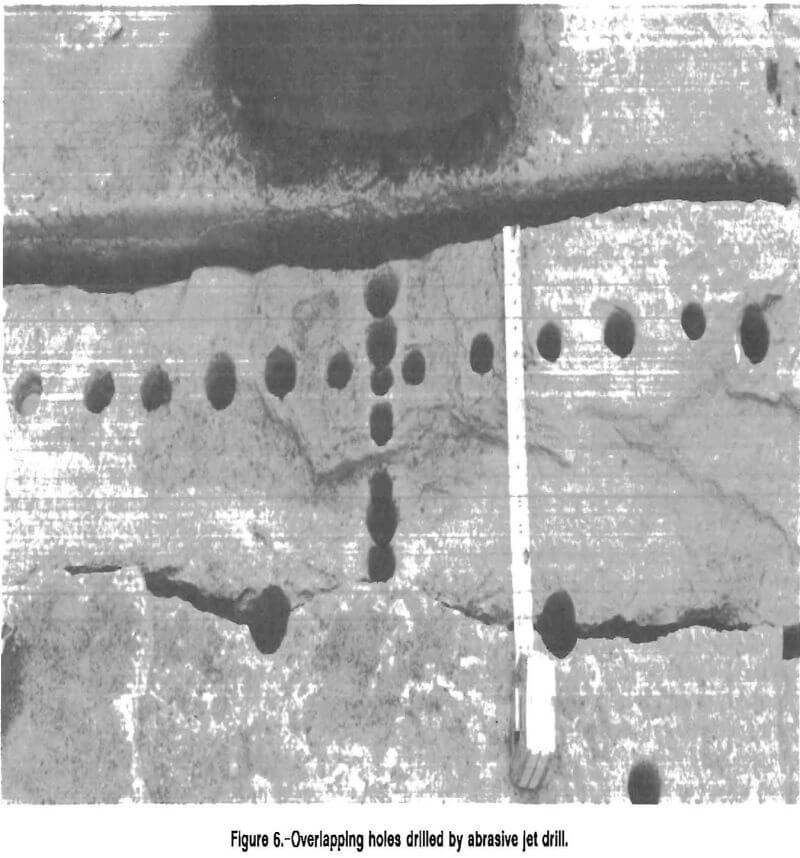

- Can drill holes that overlap (fig. 6). Overlapping holes can be strung together to create a kerf.

- Can make small-diameter (less than 1 in) holes. These small holes are ideal for resin-grouted rock bolts because their smaller size decreases the volume of grout required.

Conventional rotary or percussive rock drills are incapable of performing the functions described under items 5, 6, and 7.

Abrasives

The drilling abilities of garnet and silica sand were compared by drilling for 10 s with the abrasive jet drill, measuring the volume of each hole, and comparing the volume data (table 2). Three holes were drilled into blocks of Sioux Quartzite with each abrasive. These samples have an unconfined compressive strength of 73,000 psi. These data indicate that, on a per-pound basis, the New York garnet is 63 pct and the Idaho garnet is 40 pct more effective than silica sand in drilling Sioux Quartzite. However, silica sand is used in most of the routine drilling because it is much less expensive.

Parametric Drilling Studies on Nickel Ore

Parametric test drilling was conducted on samples of nickeliferous breccia and gneiss from the nickel district of Sudbury, Ontario, Canada. The objective was to enhance the effectiveness of the abrasive jet drill as a first step in the development of a blasthole drill or roof drill suitable for use in the hard rock in mines in the Sudbury district. The parameters investigated were (1) water pressure, (2) drill fluid chemistry, (3) drill rotation speed, and (4) pipe size.

Water Pressure

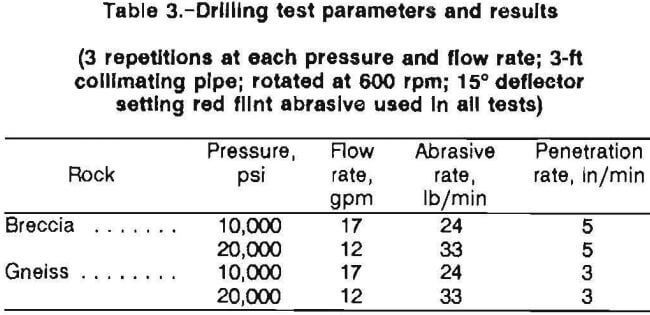

An important purpose of the testing was to determine if the drilling rate could be increased by increasing the pressure of the water jet while keeping the total power constant. Table 3 compares the results of drilling at 10,000 and 20,000 psi.

Many pumps used in water-jet cutting can be operated over a range of pressures and flow rates. Since the total power delivered by the pump is limited, an increase in the pressure of a jet is normally accompanied by a decrease in flow rate. In order to see if the drilling rate could be increased by an increase in the pressure delivered by the pump, drilling was conducted at 10,000 psi, 17 gpm and compared with drilling at 20,000 psi, 12 gpm. The results of this test are given in table 3, along with the drilling parameters. Three repetitions were performed at each pressure and flow rate. The rate of advance of the drill into the hole was preset. If the hole deepened at a rate equal to the drill advance rate, a hole was drilled through the rock and the trial was deemed successful. If the hole deepened at a rate slower than the drill advanced, the drill rod would stick in the hole and the trial was deemed a failure.

These test data show that there is little advantage in operating the drill at 20,000 psi. A 10,000-psi jet appears to be as effective as a 20,000-psi jet of comparable horsepower. This is not surprising because the cutting ability of a water jet is determined primarily by the energy in the jet. Lower pressure operation is desirable because the equipment experiences much more wear when the drill is operated at 20,000 psi.

Drill Fluid Chemistry

A series of drilling tests were performed in breccia, using various levels of a commercially available polyacrylamide additive, to determine the effect of additive concentration on penetration rate. The long-chain polymer additive has been used for 15 years as a collimating agent by the water-jet-cleaning industry. The following four additive concentration levels were tested: 0.3, 0.15, 0.075, and 0.0375 vol pct. Penetration did not increase at the first three levels and the drill stuck. The 0.0375-pct addition increased the drilling rate about 1 in/min. These results are at variance with the practice of the water-jet- cleaning industry, which claims that a concentration of 0.3 vol pct is optimum for maintaining collimation of water jets.

Drill Rotation Speed

Tests were conducted to determine the effect of rotation speed on the penetration rate in breccia. Tests were conducted at 250, 500, 750, 800, and 1,000 rpm, with constant conditions of 20,000-psi, 12-gpm, red flint abrasive. A penetration rate of 6 in/min was achieved, but the rotation speed was shown to have only a small effect on penetration rate. The optimum penetration rate was found to occur between 600 and 1,000 rpm.

Pipe Size

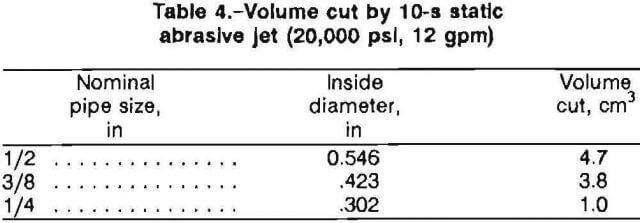

It was suggested that drilling rates might be enhanced if the velocity in the collimating pipe was increased by forcing the discharge from the pump to flow into a smaller collimating pipe. It is not possible to drill with pipes smaller than 0.5 in because no method exists for attaching deflector plates onto smaller pipe. Accordingly, static cutting tests were performed to determine if the pipe size affected penetration rate.

In these tests, the collimating pipe was placed at a standoff distance of 1 in from the rock, and a jet from each pipe impacted the rock for 10 s. The volume cut was measured. Table 4 contains the data. These data indicate that the cutting ability decreases with decreasing pipe diameter.

Polyethylene Oxide Additive

An experiment was performed to determine the effectiveness of the zeta-potential drilling fluid polyethylene oxide in the abrasive jet cutting of Sioux Quartzite. The Bureau’s abrasive jet drill operating at 10,000 psi, 17 gpm was traversed across a block of quartzite at 5 in/min using the following different types of jets: (1) water only, (2) water and abrasive, (3) water with 50 ppm polymer, (4) water, abrasive, and 15 ppm polymer, and (5) water, abrasive, and 50 ppm polymer. The results of the tests were compared. The volume of rock cut in each test was measured, and these measurements were compared. This trial showed that 15 ppm of polymer enhanced cutting 5.5 pct, while 50 ppm of polymer enhanced cutting 3.9 pct as compared with abrasive jets without polymer. This level of rock cutting enhancement can be explained in terms of reduction of friction in the flow of fluid through the pump and drill.

Kerfing

Long, narrow kerfs (fig. 7) can be cut if the collimating pipe is rotated and translated simultaneously. If the pipe is fed into the kerf as cutting proceeds, the kerf can be cut deep. Kerfs have been cut 34 in into Salem Limestone and 19 in into Oneota Dolomite.

A narrow (1-in) kerf was cut through a block of nickeliferous breccia (fig. 8) from the Sudbury region of Ontario, Canada. This kerf was cut by repetitively translating a rotating drill across the rock at the rate of 5 s/in, using a 10,000-psi, 17-gpm abrasive jet. The drill was rotating at 600 rpm. Red flint abrasive was fed into the jet at the rate of 24 lb/min. The kerf measures 6.5 by 1.25 by 16.5 in and took 26 min to cut.

The relatively long time taken to cut a kerf is a reflection of the fact that kerf cutting is less efficient than drilling. This inefficiency results from nonuniform cutting caused by inhomogeneities in the rock. Harder material is cut more slowly than the adjacent softer material, creating high spots in the kerf. The collimating pipe cannot penetrate deeper than the depth of these high areas. This causes a longer than optimum standoff distance because the collimating pipe is not able to penetrate to within an inch of the bottom of the cut in the softer areas.

Another problem arises when surfaces are created in the walls of the kerf, which require the incident jet to impinge upon the walls at a grazing angle. Grazing angles of incidence are inefficient for cutting because the jet’s energy is deflected rather than absorbed by the rock. Surfaces, which present a grazing angle of incidence to the jet, are created when the depth cutting by the undeviated jet outruns the width cutting by the deviated portion of the abrasive jet. In this instance, most of the kinetic energy of the deviated jet is wasted and the cuts are too narrow for the collimator to advance to within an inch of the bottom of the kerf. The standoff distance is then longer than optimum, resulting in drastically reduced cutting rates and consequent lengthening of the time needed to cut the kerf.

Summary

An abrasive jet rock drill has been built, tested, patented, and licensed for production. The drill uses a 10,000-psi, 20-gpm water jet, which entrains 22 lb/min of sand. The drill incorporates three novel components: a collimator, jet deflectors, and an unpressurized swivel.

The drill has been used to drill rock as hard as quartzite with a compressive strength of 73,000 psi. It penetrates this quartzite at a maximum rate of 4 in/min.

Other rocks drilled include the St. Cloud Gray Granodiorite (compressive strength of 20,000 psi), which can be drilled at 6 in/min, and the Salem Limestone (compressive strength of 8,000 psi), which can be drilled at 30 in/min.

The abrasive jet drill has some unique and useful features as compared with mechanical drills. It can drill small holes, collar a hole at any angle, drill through fracture zones, drill holes that overlap, be translated perpendicular to the direction of drilling to produce a narrow kerf, and chamber holes.