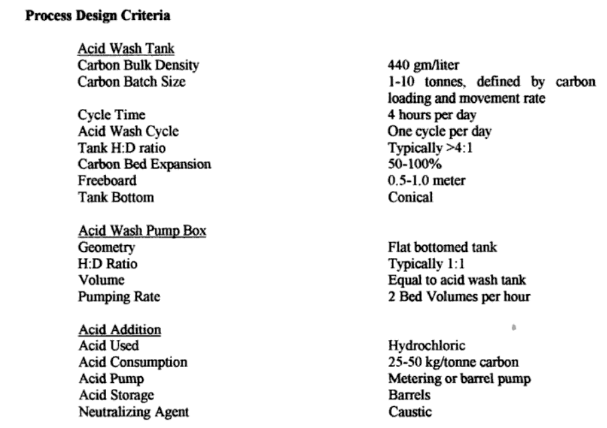

In the process of washing activated carbon, a dilute hydrochloric acid solution (3%) is circulated/pumped into the elution column. The acid dissolves inorganic foulants such as calcium carbonate, magnesium and sodium salts, fine ore Minerals such as silica, and fine iron particles. The carbon acid wash cycle takes about 4.30 hours. Acid washing may also help in removing some of the base metals such as copper, zinc, & nickel loaded on carbon.

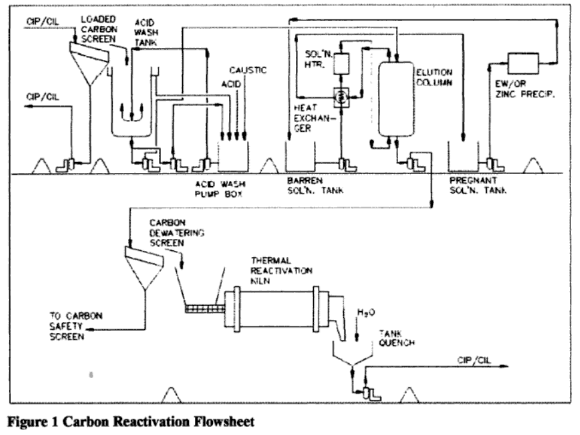

The first stage in the carbon reactivation circuit is the acid wash circuit. Early carbon circuit designs often considered acid wash after carbon elution but recent designs have typically been based on acid washing prior to elution Acid washing prior to elution has become prominent due to the following:

- Hydrochloric acid has become the predominant acid used and precious metal loss, especially silver, when nitric acid was considered has been minimized.

- The acid wash tank can be used to measure loaded carbon batch sizes.

- Most operators believe that removing scale build-up prior to elution improves the overall elution efficiency

Several operators, especially in Australia, utilize a common acid-wash elution tank. In this instance the loaded carbon is recovered in a holding tank and then transported to the elution tank for further treatment.

The objective in the acid wash circuit is to remove scale build-up on the carbon, thereby opening up the activated carbon micro-pores. The step is important to maintain the carbon’s ability to recover additional gold as well as maximize the surface exposure that will improve the overall gold elution efficiency in the downstream processing.

Early test-work in acid washing also considered the removal of base metal contaminants during acid wash. The acid washing circuit will remove some base metals but the overall efficiency is low since activated carbon has a high affinity to base metals at a low pH. Once these mechanisms were understood, it became apparent that base metals, especially copper, could be more effectively removed in the elution circuit.

Process Flowsheet

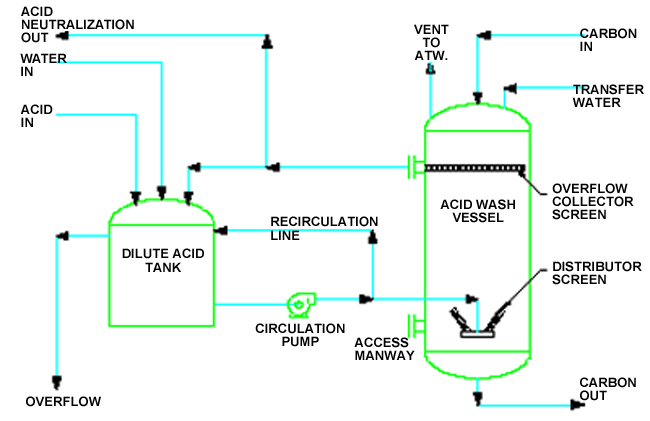

As previously mentioned there arc two predominant options for acid washing. The first option utilizes a stand alone acid wash tank while the second option utilizes the elution column as the acid wash vessel. The selection of the option depends on the operator preference, and the second option is predominantly used in Australia. In either case the circuit will include an acid wash pump, pump box and acid metering pump.

The loaded carbon will be recovered from the loaded carbon screen and transported to the acid wash tank. The acid, typically hydrochloric acid, will be metered into the acid wash pump box and the acidic solution pumped through the acid wash tank The overflow solution from the acid wash tank will return to the acid wash pump box where additional acid will added and the solution is recycled through the acid wash tank.

Once the acid wash cycle is complete the acidic solution is drained back to the acid wash pump box where it is either neutralized and discarded to tailings or retained as the solution for the next acid wash cycle.

Typically hydrochloric acid is utilized in the acid wash circuit although nitric acid has been used at several operations. Although the use of nitric acid did simplify the materials of construction, there were claims made by some carbon manufacturers that the use of nitric acid did attack the cell structure of the carbon and lead to excessive carbon fines losses after numerous cycles through the acid wash circuit These claims have caused most operators to utilize hydrochloric acid in the circuit.