Vibratory Feeders do not like wet ore much either but it is the next feeder type on my list.

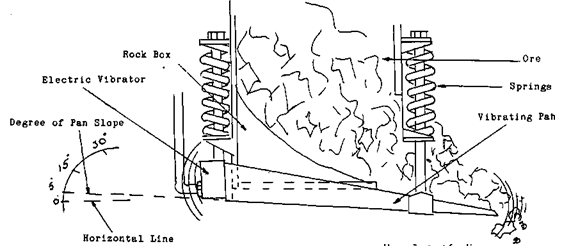

How this one works is quite simple. The feeder has two parts to it, a stationary portion and a vibrating pan. The frame or the stationary portion is attached under the ore pass. It guides the ore onto the pan that is suspended from the frame by springs. Onto this pan there is mounted a unit to provide vibration. In this day and age it is usually a magnetic type vibrator, but it doesn’t have to be, it could be an unbalanced fly wheel or a cam type. (A cam is a shaft with an offset center that has an elliptical orbit. A more detailed explanation of a cam is provided further along in the training.) When the ore is deposited on to the pan it is simply vibrated off.

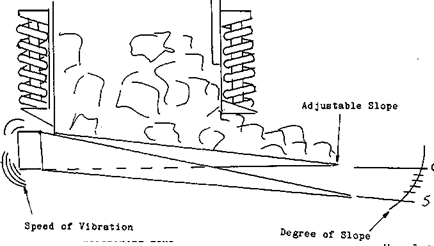

Tonnage may be adjusted in two different ways with this type of feeder, one of course is the speed of vibration, and the other is the angle of slope that the pan is set at.

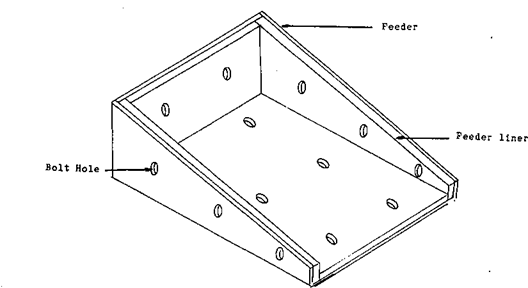

Because of the high rate of abrasion of both this feeder and the pan feeder, the metal surfaces will have a high degree of wear. This will mean a replaceable surface will have to be included into the design of the equipment. To keep the maintenance of feeders to a minimum an alloy of wear resistant metal is used to construct this portion of the feeder.

They are called LINERS, in the majority of cases due to the problems of welding this hardened metal, (many feeder liners are constructed of a magnesium alloy which is very difficult to successfully weld to other metal) the liners will be bolted in place. Later in this session we will show you how these bolts will become a problem indicator.