Table of Contents

The single line grinding circuit at Bond Gold’s Colosseum mine consists of variable speed drive semi-autogenous (SAG) milling and secondary grinding with a fixed speed ball mill.

There are several advantages and disadvantages of operating SAG mills with variable speed drives. Discussion in this paper will focus on the effects of variable speed SAG milling in relation to mill liner wear, grinding media consumption, and mill operating availability. Operating experiences, corresponding mill data, and pertinent design changes are also presented.

Comminution Circuit Description

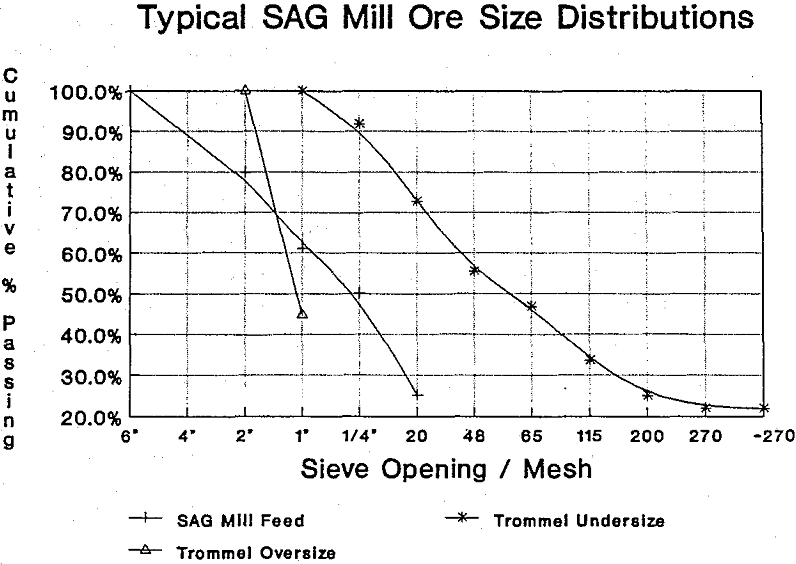

Run-of-mine ore is direct fed by 77 Mt (85 st) haul trucks, or is stockpiled and blended by front end loader, to maintain specified limits for sulphide and cyanide soluble copper content. Primary crushing is accomplished with a single stage 1.2 m x 1.5 m (48 in x 60 in) Fuller-Traylor jaw crusher. The minus 152 mm (-6 in) product is conveyed onto a 29,940 Mt (33,000 st) crushed ore stockpile, reclaimed by three vibrating feeders, and then conveyed to the SAG feed chute at a targeted rate of 136 Mt/hr (150 st/hr).

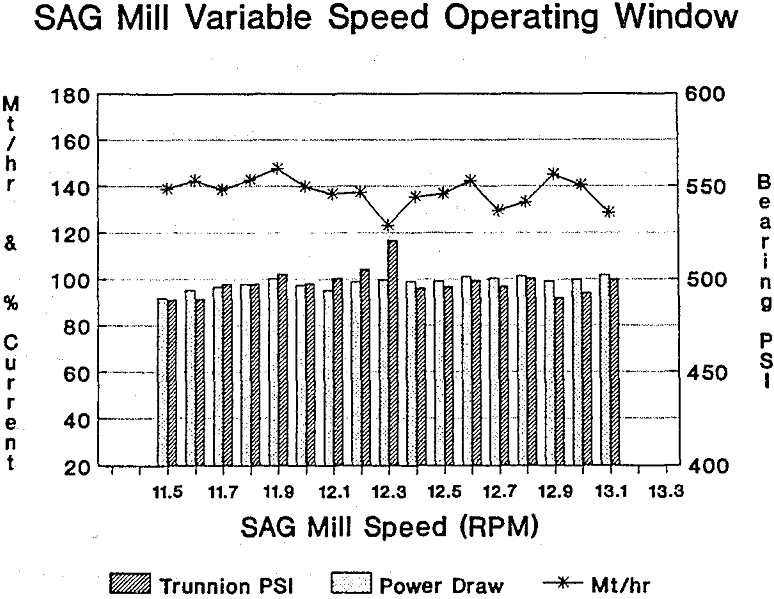

The control strategy for the SAG mill is fairly basic. Parameters which can be adjusted are feed tons per hour and mill speed. The combination of the two are used to maintain a target feed trunnion bearing pressure of 520 psi, and power draw between 95% and 105% of available current (2,620 amps).

Water addition to the SAG feed chute is manually regulated to maintain the SAG discharge slurry at 70% to 72% solids by weight. The three vibrating feeders from the crushed ore stockpile are tied into a controller which maintains a set point tonnage.

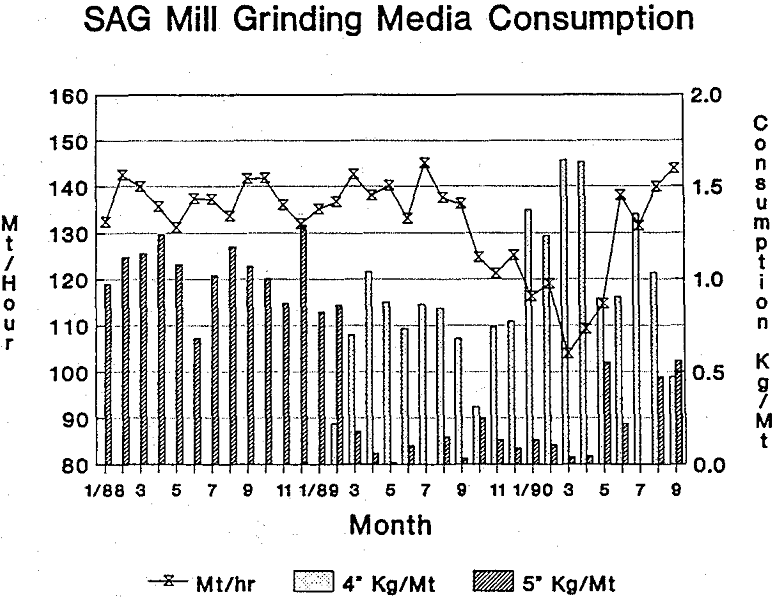

During the first year of production, excessive wear patterns on the discharge head filler rings and discharge end shell liners and lifters posed concern. An initial remedy was the addition of 102 mm (4 in) grinding balls, with minimal 127 mm (5 in) ball addition.

The second step to decreasing high wear rates was to reduce the maximum operating speed on the SAG mill from 13.2 RPM (78% of critical speed) to 12.7 RPM (75% of critical speed).

Justifications were made for the installation of an Omnicone crusher on the SAG pebble oversize material. Conservative estimates were made that as little as a 10% increase in tonnage would pay back the capital investment in less than six months. Successful commissioning of the crusher in May 1990, resulted in an initial production increase of 20%.

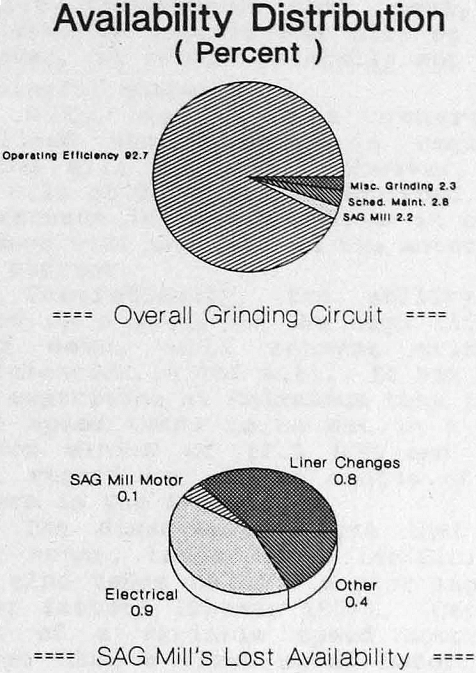

Mill Availability and Maintenance

In the past two years, overall grinding availability has averaged 92.7%. Mill availability of better than 90% is maintained at Colosseum by using 2.8% of the available hours per month to perform preventative tasks on the SAG mill and other equipment in the grinding circuit.

Advantages and Disadvantages

The greatest advantage of the D.C. motor, at Colosseum, is its ability to change speeds to accommodate the variability in the ore’s work index and feed sized distribution from one shift to the next. The primary jaw crusher operates one shift per day, peaking out the stockpile with enough tonnage to mill for the dark shifts.

The disadvantages are that the D.C. motor, tends to be inefficient, and also tends to have a poor lagging power factor. Capital cost of a variable speed motor is higher than a fixed speed motor, but the biggest disadvantage of utilizing a D.C. motor, as a general rule of

Variable Speed SAG Mills Motor Capability vs Mill Capability

The specification of the prime mover of an autogenous/semi-autogenous mill involves an analysis of the likely operating conditions within the mill and the choice of a nominal operating speed. For variable speed mills, the operating range for mill speed has to be defined so that mill power/torque requirement can be matched by the motor power/torque capability. This paper will describe how this relationship can be influenced by ore grindability.

This optimum mill speed has to be selected to accommodate the most probable operating conditions with respect to:

- development of the ore charge level, and

- development of the ball charge level, both leading to

- development of the total mill charge level and the most efficient grinding action consistent with the desired feed rate and power draw.

It also follows that the starting torque requirement for variable speed drives is much lower than for fixed speed drives since the mill starts from rest and follows a programmed starting sequence, including the capability of detecting a frozen mill charge, should it exist.

A typical relationship of motor power/torque output, M1, with mill speed is illustrated for a nominal (or rated) motor speed equivalent to 72% CS. Examples of the power requirement developed by a mill charge as mill speed increases have been added for a 10% v/v ball charge at different total mill charge volumes ranging from 15-30% v/v.

It can be seen that the risk of improper selection of nominal (or rated) motor power and speed can be considerable if an appreciation of how the ore is (or is not) going to develop a particular total mill charge is not addressed.

Ore grindability is usually measured in terms of Bond work index or, as in the case of autogenous/semi-autogenous mills, operating work index. This operating work index can usually be related to the equivalent pilot plant value for a given set of conditions, e.g., specific power consumption, kWh/t, and 80% passing size of the primary mill circuit product, in order to establish the required primary mill power for a given ore type.

Lesser competent ores which have U.C.S. values in the range 10,000-15,000 psi do not develop total volumetric charge levels in excess of 25% v/v. A typical range would be from 13-20% v/v with a higher ball charge of 10-12% v/v and operating at speeds less than 75% CS.

The ability of a mill motor to drive an autogenous/semi-autogenous mill over a defined operating speed range is dependent on selection of the nominal (or rated) motor speed such that the resultant mill speed is close to the upper limit of the operating speed range