The first step in the quarrying of granite, following removal of any overburden material, involves the freeing of large blocks from the formation. For many years the use of explosives was the accepted method of obtaining these blocks. Even today there are operations where this is considered to be the most economical method even though it does result in a high percentage of damaged stone. In more recent times the preferred procedure at most quarries has been to produce a continuous vertical cut or slot completely around the block to be separated. Originally, this was done by drilling a series of closely spaced holes around the block and breaking the web between the holes with a chisel-like tool known as a broaching bar. The machine used in this mechanical method of producing the relief slot is known as the channel bar.

The Thermal Spalling Process

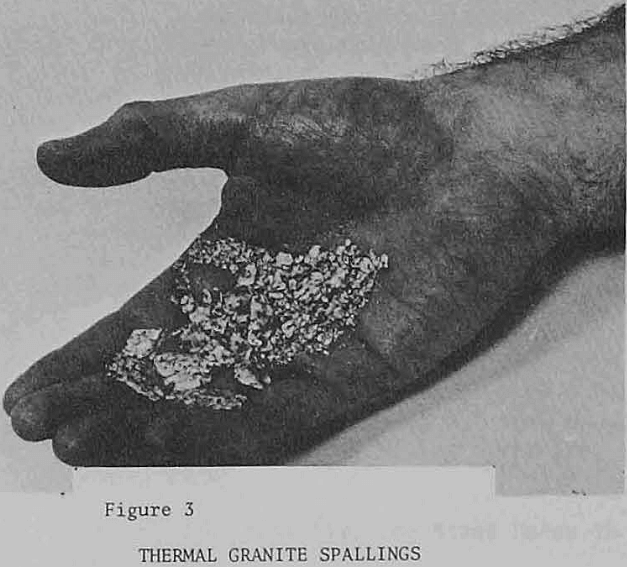

The application of a thermal device on rock depends upon a characteristic of the rock termed “spallability”. In its simplest terms spalling is considered as decrepitation resulting from differential expansion of rock crystals due to thermally induced stresses. The individual rock properties influencing the spalling characteristic are so numerous and their interaction so complex that it has been impossible to date to accurately predict the reaction of any particular rock to a high temperature source of heat. Perhaps computers will eventually aid in making predictions with a high degree of confidence, but for the present it is necessary to impose the, thermal shock conditions on a sample of the rock to establish its spalling characteristics.

Through years of laboratory and field work, we have been able to ; identify the individual properties that influence the spalling tendencies of rock. The properties most favorable to a high degree of spallability are:

- Large linear thermal expansion at temperatures below 700°C.

- High thermal diffusivity at temperatures below 400°C.

- Equigranular interlocking structure with little or no fine-grained clay or mica alteration products.

- No significant amounts of soft, low-melting, or elastic mineral or materials which yield after thermal decomposition.

Jet Channeling Equipment

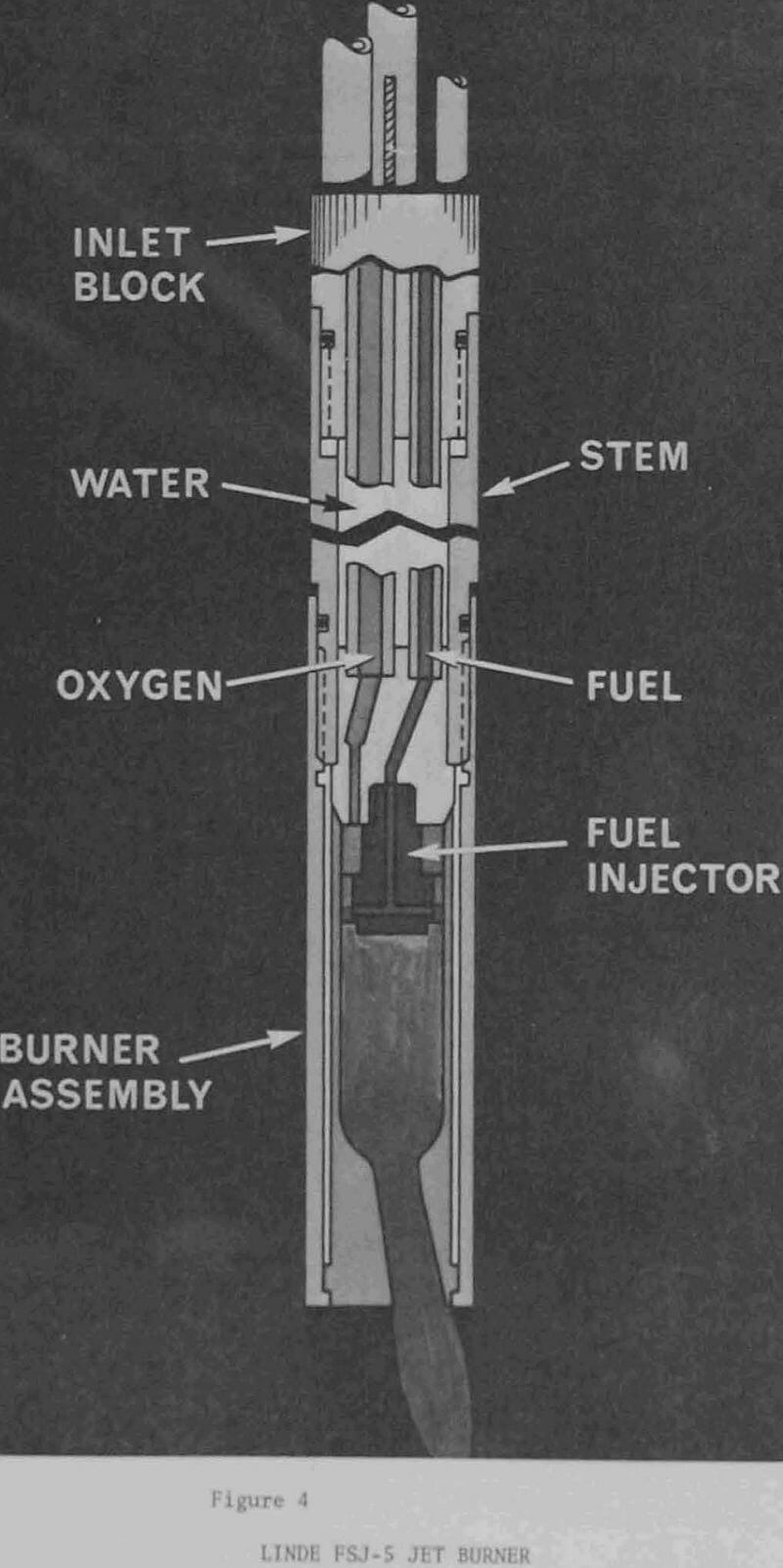

The three process fluids, oxygen, fuel and water enter at the top of the blowpipe and are conducted through separate conduits to the burner. While the basic design of the blowpipe has remained relatively unchanged for 10 years, continued modifications to the burner and fuel injector have resulted in improved combustion efficiency and process performance.

The original burner was designed to use 65 lbs./hr. of liquid fuel such as kerosene or fuel oil, 1500 cu. ft./hr. of oxygen, and 85 gal./hr. of cooling water. It produces an exhaust flame that has a temperature of approximately 4000 °F. and a velocity of about 5300 ft./sec. Its horsepower equivalent, based on a diesel efficiency, of approximately 110 hp. represents a high concentration of energy in a combustor less than an inch in diameter. Burners of even greater intensity have been developed, and will be discussed at greater length later in the paper.

In addition to the blowpipe, several pieces of additional equipment are required. Sources of the three process fluids are an obvious necessity. Most operations will also utilize a process fluids metering system and some type of blowpipe suspension device. Figure 5 is an artist’s drawing of a typical jet channeling set-up. The source of oxygen and water are indicated as being transmitted to the operating area through pipe lines from the surface. There are many variations of the blowpipe suspension device; but generally, an A-frame unit is employed.

During the last several years, compressed air has been used as the oxidant in place of oxygen on some jet channeling burners. The exhaust flame from these burners has a lower temperature, lower velocity, and a greater mass flow for equivalent BTU rating compared to oxygen burners. The air blowpipe is particularly well suited for exploratory work in areas remote from a source of oxygen. Since the “air burner” is a newcomer to the field of jet channeling, it is not possible at the present time to predict its eventual share of the market relative to the oxygen burner.

Recent Process Developments

The Linde Newark Laboratory pursues a constant development program directed toward process improvements which will result in lower unit operating costs. Figure 10 is a photograph of the Laboratory’s jet channeling test facility. Tests are conducted on sample blocks which might weigh as much as 10 tons. The facility is automated as much as practical to eliminate the human element variable. Tests are conducted at a given set of conditions until consistently representative results are obtained assuring that the results are not being affected by some extraneous influence.