In this module, I’ll take you through the key aspects related to underground mining activities. In this module, we will look at economic considerations in regard to underground mining, geological conditions suited to underground mining, the different operational and technical approaches using underground mining and important operational considerations including roof support, ventilation, safety, water management and post mining issues such as substance and closure. Let’s start by looking at some of the economic considerations that are specific to underground mining. In module one, we took a look at the economic considerations for mining in general and the principles we explore there are relevant here. However, the unit of rock excavating underground mining tends to be more costly than surface mining operations and this has consequences for the assessment of economic viability in underground mining. Some deposits that are uneconomical to mine using surface techniques are economical with underground mining methods and vice versa. This is because every geological situation in every mine is different. There are many reasons why underground mining is so much more expensive than surface mining operations concealed on a permanent basis. These include the presence of a rock roof or hanging wall that is overlying rock above the operation and the necessity of managing the risk associated with working beneath it. This has a substantial impact on mining costs. The added complexity of getting all of this excavated to the surface within a more highly constrained environment and the management of other risk related to underground operations such as water in-rush, poor visibility and poor air quality. The most basic economic consideration comes down to the ratio of the amount of water that can be produced and the amount of worthless rock that must be moved in order to produce it.

However, the unit of rock excavating underground mining tends to be more costly than surface mining operations and this has consequences for the assessment of economic viability in underground mining. Some deposits that are uneconomical to mine using surface techniques are economical with underground mining methods and vice versa. This is because every geological situation in every mine is different. There are many reasons why underground mining is so much more expensive than surface mining operations concealed on a permanent basis. These include the presence of a rock roof or hanging wall that is overlying rock above the operation and the necessity of managing the risk associated with working beneath it. This has a substantial impact on mining costs. The added complexity of getting all of this excavated to the surface within a more highly constrained environment and the management of other risk related to underground operations such as water in-rush, poor visibility and poor air quality. The most basic economic consideration comes down to the ratio of the amount of water that can be produced and the amount of worthless rock that must be moved in order to produce it.  This is because the cost of moving worthless rock is lower for surface mining operations that these friendly grand mining operations so when there is a lot of worthless rock to move surface mining operations are usually superior. However, if the ore body can be accessed through underground operations removing little or no worthless rock in the process then underground mining operations may end up being economically superior to surface mining even through really shallow deposits. Another important economic consideration in underground mining is the extent of water recovery because it’s very difficult to remove all of the ore in underground mining operation. Invariably, as underground operations progress and excavations become larger it becomes necessary to leave amounts of the ore body behind to support the roof in the form of pillars. In surface mining activities it is generally possible to remove all of the re-sizzles provided the miner of course is willing to dig a deep enough hole. The selection of a mining method doesn’t have to be exclusive; sometimes it’s most economical to mine a deposit using a combination of underground and surface mining techniques.

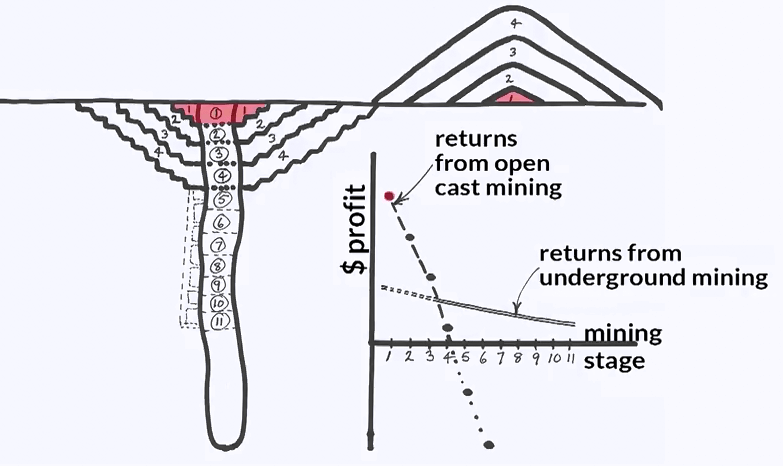

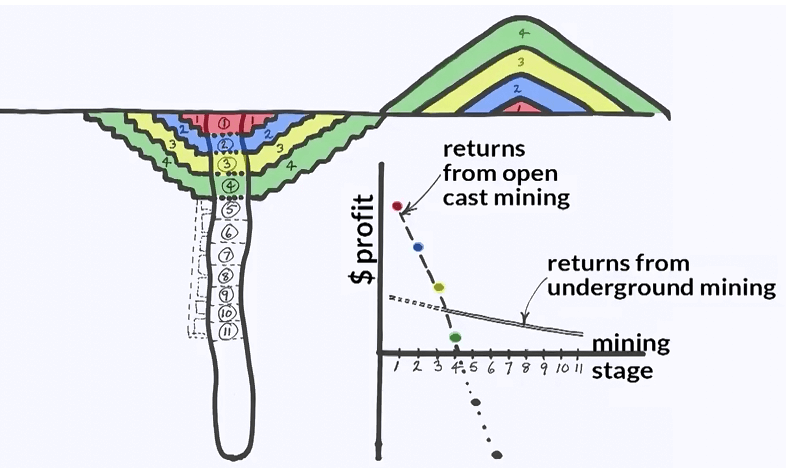

This is because the cost of moving worthless rock is lower for surface mining operations that these friendly grand mining operations so when there is a lot of worthless rock to move surface mining operations are usually superior. However, if the ore body can be accessed through underground operations removing little or no worthless rock in the process then underground mining operations may end up being economically superior to surface mining even through really shallow deposits. Another important economic consideration in underground mining is the extent of water recovery because it’s very difficult to remove all of the ore in underground mining operation. Invariably, as underground operations progress and excavations become larger it becomes necessary to leave amounts of the ore body behind to support the roof in the form of pillars. In surface mining activities it is generally possible to remove all of the re-sizzles provided the miner of course is willing to dig a deep enough hole. The selection of a mining method doesn’t have to be exclusive; sometimes it’s most economical to mine a deposit using a combination of underground and surface mining techniques. Take for example a high grade vertical or nebo vertical body say a kilometer deep initially is indicated by stage one in the drawing, it is most economical to dig directly into the top of the ore body and to take off in the open pit. Mining can then follow the opening downwards but as we learned in module three, very hard vertical walls become unstable and they must be batted back to a stable slip to ensure the pit walls don’t collapse. As the pit gets deeper, stages two, three and four the amount of worth of surrounding rock that must be removed to allow another level of oil body to be mined increases rapidly. At some point the cost of widening the pi-dicks the value of the ore mine and the open pit mining becomes uneconomical. This maybe the depth of several hundred meters. In the figure it is illustrated by the graph of profit versus mining stage and it occurs after stage four. If however the restore valuable or deeper levels then it may be economical to switch underground mining methods and chase the ore body down to very deep levels. These can be mobilized through the base of the abandon pit in order to reduce the underground transport distances. In the figure this is represented by stages five to eleven. Whilst the cost of mining at deeper levels increases it remains profitable because there is little worthless rock to remove. As another example, let’s consider a dipping same of coal, initially where the coal seam comes to surface, stage one, it is most economical to dig directly unto the coal.

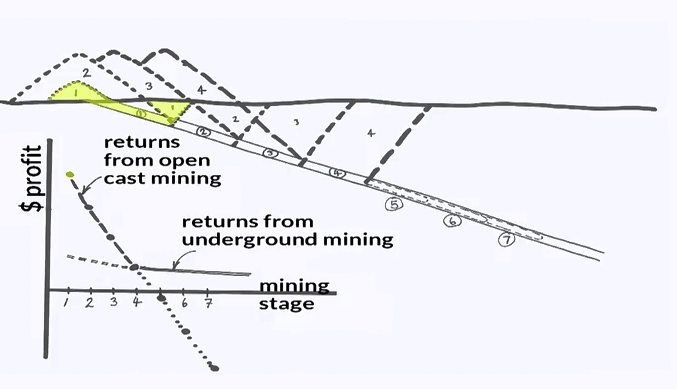

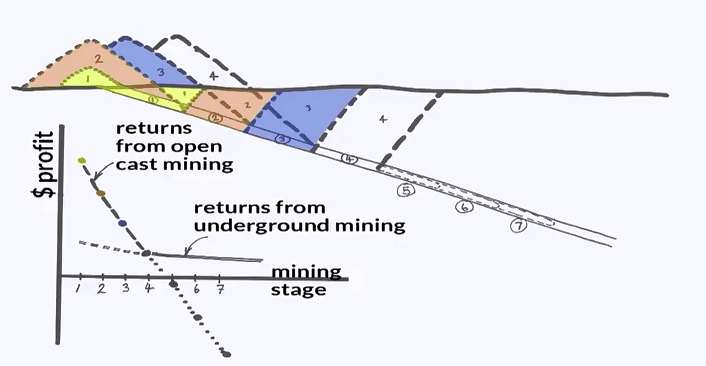

Take for example a high grade vertical or nebo vertical body say a kilometer deep initially is indicated by stage one in the drawing, it is most economical to dig directly into the top of the ore body and to take off in the open pit. Mining can then follow the opening downwards but as we learned in module three, very hard vertical walls become unstable and they must be batted back to a stable slip to ensure the pit walls don’t collapse. As the pit gets deeper, stages two, three and four the amount of worth of surrounding rock that must be removed to allow another level of oil body to be mined increases rapidly. At some point the cost of widening the pi-dicks the value of the ore mine and the open pit mining becomes uneconomical. This maybe the depth of several hundred meters. In the figure it is illustrated by the graph of profit versus mining stage and it occurs after stage four. If however the restore valuable or deeper levels then it may be economical to switch underground mining methods and chase the ore body down to very deep levels. These can be mobilized through the base of the abandon pit in order to reduce the underground transport distances. In the figure this is represented by stages five to eleven. Whilst the cost of mining at deeper levels increases it remains profitable because there is little worthless rock to remove. As another example, let’s consider a dipping same of coal, initially where the coal seam comes to surface, stage one, it is most economical to dig directly unto the coal.  Then to mine more of the coal a strip of other burden needs to be removed to expose some of the deeper coal as was described in module three. This approach can continue repeatedly until the amount of overburden that must be removed to expose more coal becomes economically prohibited. Currently around one hundred or around a hundred and twenty meters, this has showed in the figure in stage five. Then, mining must be abandoned or else the mining method must switch to underground methods. Underground mining can then access, the same directly from the base of the high wall. Mining is more difficult and recovery is reduced but the mining is profitable since there is very little waste to remove. Not surprisingly, one of the principle task of the mining engineer is to design mining operations which extract the greatest amount of ore thus minimizing the amount of worthless rock that is handled. We are going to look at some of these aspects of underground mining in the topics that follow. Fundamental factor in determining the ratio of ore to waste rock produced is the size shape and position of the ore body. This is generally related to the type of ore and to the geological origin of the ore body.

Then to mine more of the coal a strip of other burden needs to be removed to expose some of the deeper coal as was described in module three. This approach can continue repeatedly until the amount of overburden that must be removed to expose more coal becomes economically prohibited. Currently around one hundred or around a hundred and twenty meters, this has showed in the figure in stage five. Then, mining must be abandoned or else the mining method must switch to underground methods. Underground mining can then access, the same directly from the base of the high wall. Mining is more difficult and recovery is reduced but the mining is profitable since there is very little waste to remove. Not surprisingly, one of the principle task of the mining engineer is to design mining operations which extract the greatest amount of ore thus minimizing the amount of worthless rock that is handled. We are going to look at some of these aspects of underground mining in the topics that follow. Fundamental factor in determining the ratio of ore to waste rock produced is the size shape and position of the ore body. This is generally related to the type of ore and to the geological origin of the ore body.

https://youtu.be/-_rt0sU2XSE

In the next topic we’ll take a look at those geological situations and ore bodies that are best suited to underground mining techniques.