During the winter and spring of 1917, an unprecedented number of underground fires occurred in the Butte district. With one exception, these fires were caused by the failure of electrical equipment, and called attention to the increased fire hazard in underground mining operations occasioned by the extensive use of electricity.

Five local conditions that contributed toward a heavy fire risk were:

- The heavy continuous timbering necessary for mine supports;

- the strong ventilating pressures in the shafts and main airways;

- the subsidence and faulting movements in the country rock, which ruptured cables and displaced trolley and lighting wires;

- the strongly acid mine waters, which quickly developed any weak points in the electrical insulation;

- oxidation in old stopes containing large amounts of timber.

In the summer of 1917, a comprehensive plan of fire prevention was begun by the Anaconda Copper Mining Co., which involved a thorough and intensive development of the preventive measures then in use. These were as follows: Fireproofing, remodeling and strengthening electrical insulations, extension of underground water system, control of ventilation, maintaining efficiency of fire-fighting crews, and reorganization of fire patrol.

In considering the problems of fireproofing, it was immediately apparent that some method of applying a durable coat of fireproof material to the mine timbers was needed. The first experiments were made with a plaster composed of one part cement, one-half part fireclay, and three parts sand. This was applied by hand to a thickness of 1 in. (2.5 cm.) over a reenforcement of herringbone metal lath. It made a very satisfactory covering for fan stations, but was too soft and friable for traveling ways, where it was subject to abrasion. The cement gun was tried next with a three to one mixture of sand and cement. A ½-in. coating of gunite applied over poultry netting or metal-lath reenforcement proved to be durable and fire resisting. Preparations were then made to fire-proof the Tramway No. 1 hoisting shaft.

This was a four-compartment shaft, 2475 ft. (754 m.) in depth; it was lined with framed shaft sets of 12-in. (30 cm.) fir timber; the sets were 7 ft. by 18 ft. 10 in. over all, and were spaced 5 ft. on centers. The sets were lagged with 2-in. pine plank, placed against the rock walls. The timbers and lagging were covered with a ½-in. coating of cement, applied with the cement gun over 27 gage diamond-mesh metal lath. The fire-proofing operation was completed in the fall of 1917. Because of the success of this operation, it was decided that the twenty-four main hoisting shafts operated by the Anaconda Company in the Butte district, not already so, should be made downcast shafts and fireproofed along these lines; also that the same treatment should be given all surface tunnels carrying steam, air, and electric power from plant to mines.

Twelve type N-I cement guns were procured and the work pushed as fast as operating conditions would allow. One or more shafts at a time were withdrawn from ore production, retimbered where necessary, and fireproofed under the direction of the mine foreman. Each foreman selected a crew, from among his shift bosses and shaftmen, who were trained at one of the mines where fireproofing work was in progress. The work was carried on continuously by three 8-hr. shifts. The crew for each shift consisted of one shift boss; six shaftmen, who nailed on the metal-lath reenforcement; two nozzlemen for the cement gun; two runners for the cement gun; station tenders; topmen; etc. The fireproofing work has been completed at the High Ore, Moonlight, Tramway, Rarus, Mountain View, Leonard, and Belmont mines. It is in progress at the Pennsylvania and Diamond mines, while preparations are being made at the Original and East Colusa mines.

Regarding the details of the gunite work, some general conclusions may be summarized. Poultry netting makes satisfactory reenforcement for covering wooden surface structures of continuous plane surfaces, such as buildings and ore bins; expanded-metal lathing is to be preferred where much fitting is necessary, as on underground timbering. A gunite covering ½ to ¾ in. thick on wooden surfaces is sufficient for fireproofing purposes. The sand should be clean and should be screened through a screen four or five meshes to the inch. If the sand is very dry, it does not mix well with the cement; 6 to 10 per cent, moisture is best. Moisture in excess of 15 per cent, is liable to block the material hose. A mixture of three parts of sand to one of cement is best. A water pressure of at least 40 lb. per sq. in. is desirable; the air pressure may be from 40 to 100 lb. per sq. in., but the air should be dry. The working air pressure in the cement gun must vary with the distance from the gun at which the nozzle is being used, but should be kept as low as will keep an even flow of material through the hose. Using a 50-ft. material hose, the pressure should be from 5 to 7 lb. per sq. in. The limit at which the nozzle can be used, with satisfactory results, is about 200 ft. vertical or 500 ft. horizontal distance from the cement gun. Under these conditions, the air pressure in the gun will be from 25 to 35 lb. per sq. in. It is important that the mixing chamber of the cement gun be cleaned out every second or third day when the gun is used continuously; the cement finds enough moisture to set on the rotating plate, where it clogs the feeding channels. A ½-in. mesh screen fastened over the hopper of the cement gun obviates many delays. There should be at least one experienced man in a cement-

gun crew; new men are quickly trained, but an inexperienced crew gets very poor results. The figure used in making estimates for materials was 1 cu. ft. of sand to 7½ sq. ft. of surface gunited ¾ in. thick.

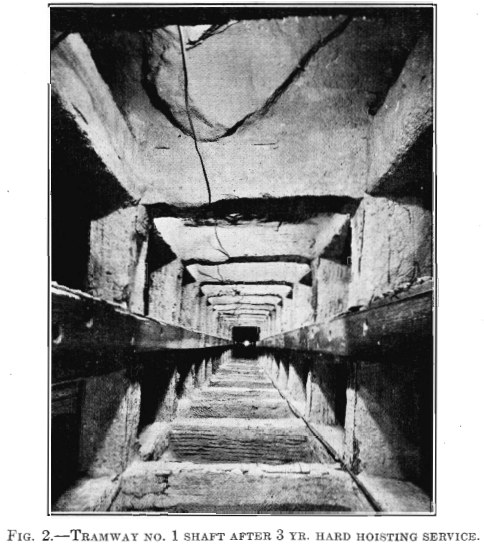

The Tramway shaft has had 3½ yr. continuous service in ore production since the fireproofing work was completed. A recent inspection of the shaft showed that the timbers from the surface to the 1600-ft. level were 92.5 per cent, covered with gunite; from the 1600-ft. to the 2800-ft. level, the timbers were 85 per cent, covered with gunite. The depreciation of the gunite is due to falling rocks from overloaded skips. In wet parts of the shaft, where there has been sufficient ground pressure to buckle the timber, there is a tendency for the acid mine water to run between the timber and the gunite covering. This eats away the nail fastenings and loosens the gunite. The damage from this cause has been slight up to date. It can be controlled by proper attention to drainage.

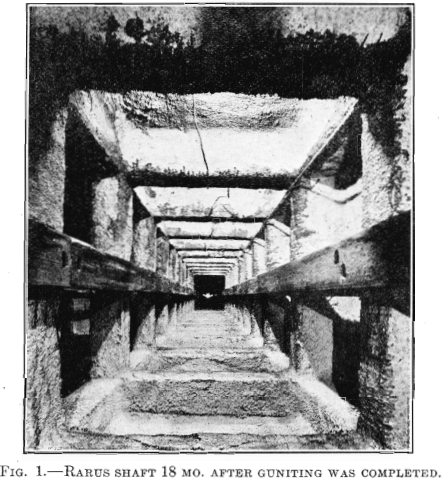

Fig. 1 shows the Rarus shaft, taken 18 mo. after the guniting had been completed. The cages have been operated about one third of the time; the shaft is dry and there has been but slight movement of the

timbers. The depreciation of the gunite is hardly noticeable. Fig. 2 shows the Tramway No. 1 shaft after 3 yr. hard hoisting service. There have been occasional deluges of “copper water” in the shaft from fire-fighting operations; ground pressure is heavy at several points. The effect of these conditions on the gunite can be seen by comparing Figs. 1 and 2. It will be noticed that the gunite is cracked and that the timbers are exposed in small patches; this, however, does not seriously affect the fireproof qualities of the covering as a whole. A timbered surface tunnel under a railroad fill had been gunited, but the gunite covering was damaged by workmen, who found it necessary to remove numerous small portions of gunite. The flames from an adjacent surface fire swept through the tunnel for 30 min., melting the lead packing from the joints of a 16-in. cast-iron air line. But an inspection of the tunnel showed that though the timbers had been burned away to a depth of 1 or 2 in. wherever the gunite had been removed, there was no tendency for the fire to spread behind the gunite covering.

Gunite has been applied to all wooden structures adjoining the mine shafts; including ore bins, subways, etc. The timbers and lagging in the shafts, skip chutes, and stations have been covered with gunite; at intervals of 100 ft., the lagging has been removed and the concrete covering carried back to the rock walls, so as to hermetically seal the timbers into sections, see upper foreground Fig. 2. This should prevent spread of fire in the timber between the rock walls and the fireproof covering. In the underground pump stations, the timbers have been gunited as have also the approaches for a distance for 50 ft. or more.

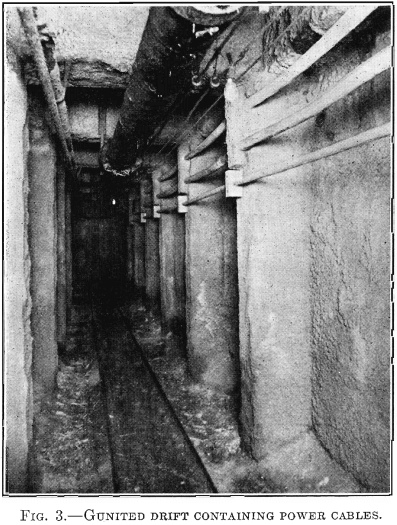

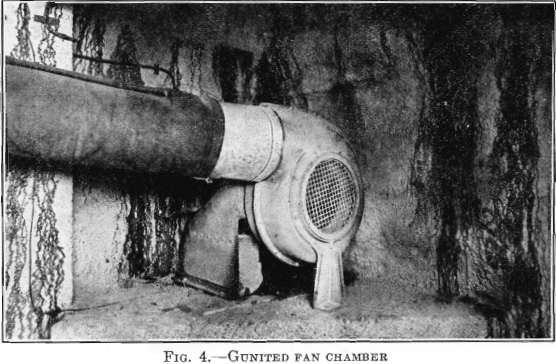

Rooms for switch panels have been cut in the walls adjacent to the pump stations; the supports for the roof and walls of the switch rooms are made of structural steel and concrete. Transformer and motor-generator sets are also isolated in rooms supported in the same manner. All crosscuts or drifts carrying power cables are gunited for the entire length of the contained cables, see Fig. 3. Where such crosscuts are untimbered, the rock walls are covered with a 1-in. coat of gunite; this prevents slacking of the walls and roof. The underground fan stations are fire-proofed with gunite. Where possible, timbers are left out and the walls covered with gunite. The air passages leading from the shaft to the large booster fans are gunited throughout. The guniting is carried for 75 ft. beyond the exhaust of the fans. The smaller fans, Nos. 2½,

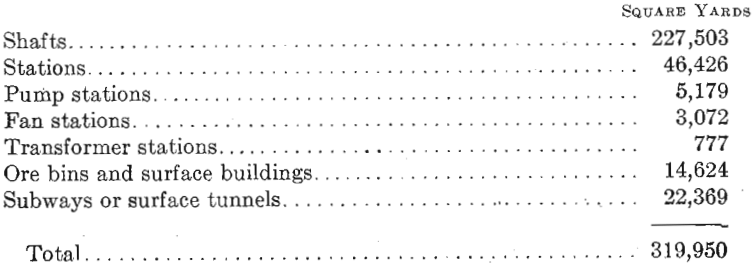

4, and 6, Sirocco, are enclosed in a fireproof covering, and one or more sets of adjoining timbers are covered with gunite, see Fig. 4. The timbers are gunited wherever oil or blasting powder are stored. The total amount of surface gunited to date is as follows:

The electrical equipment of the mines is being thoroughly overhauled. The older power cables have been replaced by new steel-armored cables; the lighting and signal cables have been renewed; especial attention has been given to the manner of making taps in the power lines and to the junction boxes and wiring on the stations. This work is described in detail by C. D. Woodward.

The underground water system has been extended so that, in all the larger mines, 1½ or 1-in. water lines have been carried into each drift, crosscut, and stope. Water is obtained from the city water system; it is carried down the shaft in 3 or 4-in. water columns. At each underground station, connections on the water columns are provided for standard 2¼-in. fire hose. Hydrostatic pressure in the water columns is kept down by means of reducing valves or tanks, placed at intervals of 400 ft. difference in elevation. In the larger installations, tanks are preferable, as they provide a reserve water supply. They are circular wooden tanks 9 ft. in diameter by 7 ft. in height, and hold 3000 gal. of water. They are equipped with a float-and-valve arrangement which automatically regulates the supply and maintains the water level within fixed limits. A hose house is located on the surface close to each shaft, where a supply of about 1500 ft. of. 2¼-in. hose is kept available for underground use. Pyrene extinguishers are placed on each station and near all electrical equipment. .

Control of ventilation is obtained by making surface fan installations reversible and by iron or cement doors placed in the main crosscuts and in the connections between mines. These doors are set in concrete frames and can be made gastight by chinking with fireclay or cement.

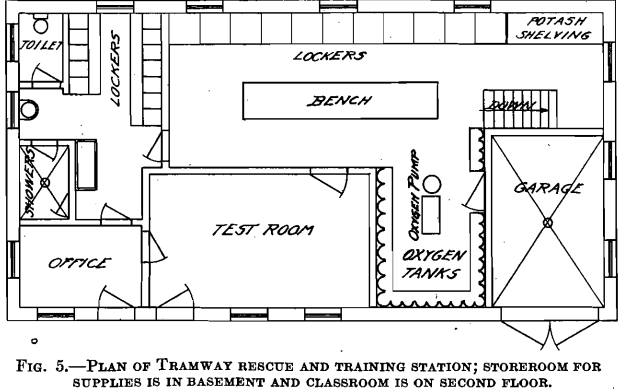

Two rescue stations are maintained by the Anaconda Copper Mining Co. in the Butte district. No. 1 rescue station, situated in the Anaconda mine yard, is equipped with twenty-one sets of Paul breathing apparatus and serves the mines in the central and western portions of the district. No. 2 rescue station, situated in the Tramway mine yard, serves the mines on the eastern slope of the Butte hill; it is equipped with fifty sets of Paul breathing apparatus. It is also used as a training station; see Fig. 5. Some nearby surface workings available for training work make it possible to give training under approximately fire conditions. A crew of from six to thirty helmet men is maintained at each mine; these men work as miners or timbermen when not actively engaged in fire fighting. Recruits are trained by the instructor, who is in charge of the station; the course prescribed by the U. S. Bureau of Mines is used. Men who have been previously trained are given 6 hr. practice once every 6 mo. About 400 trained helmet men are in the Butte district.

The older system of fire patrol was organized upon the principle of having from two to six underground watchmen (firebugs) at each mine. These men patroled the workings continuously while on shift; their hours were arranged so as to include the intervals between the operations of the two 8-hr. mining crews. The beats were necessarily long and several hours elapsed before they could cover the workings deserted by the day or night shift. Under the present system, each shift boss is responsible for the fire patrol of his beat. With the aid of an assistant, chosen from among the repairmen of his crew, he covers his beat immediately after the shift goes off; the assistants are trained helmet men. They go on shift 1 hr. later than the regular crew and receive a bonus of 10 per cent, over miner’s wages. Under the operation of this system, a force of

from eight to twelve men patrols each mine immediately after the shift goes off. The entire mine is covered within an hour.

The foregoing preventive measures have proved their efficacy. The gunite coating has stood up under several tests. In the Leonard shaft in July, 1920, the insulation of an old power cable broke down and an arc set fire to the shaft ladder; several lengths of the ladder were burned before the fire was put out. The shaft timbers, however, which had been gunited, were not damaged. A number of motors on small ventilating fans, which were surrounded by gunited timbers, have been short circuited and burned up without damage to the mine timbers. Upon numerous occasions, the advantage of having an underground water supply available has been demonstrated. Fires have been put out before they had time to spread and get out of control. In 1917, at the Tramway mine, the prompt closing of the proper fire doors turned a rush of gas into the upcast shaft and enabled the men on shift to be removed from the mine without a single casualty. Without such action, a serious loss of life might have resulted. The mine bosses should become thoroughly familiar with the ventilation of their mine. It is good practice for a mine foreman to give his bosses theoretical problems in ventilation, based on the supposition of a fire in different parts of the mine. The methodical training of Butte fire-fighting crews has resulted in high efficiency, and they have been frequently called upon for service in neighboring states, where they have done most satisfactory work.