This test method specifies the apparatus, instrumentation, and procedures for determining unconfined compressive strength of intact rock core specimens. This procedure is identical to ASTM D 2938 except that the cores are tested after cutting without grinding, and neoprene caps are used on the specimen ends.

This test method specifies the apparatus, instrumentation, and procedures for determining unconfined compressive strength of intact rock core specimens. This procedure is identical to ASTM D 2938 except that the cores are tested after cutting without grinding, and neoprene caps are used on the specimen ends.

Unconfined Compressive Strength Test Procedure

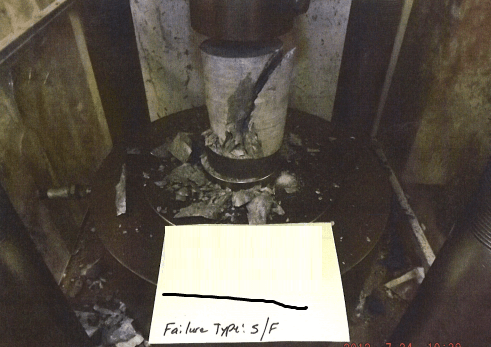

- Check the ability of the spherical seat to rotate freely in its socket before each test.

- Place the lower platen on the base or actuator rod of the loading device. Wipe clean the bearing faces of the upper and lower platens and of the test specimen, and place the test specimen on the lower platen. Place the upper platen on the specimen and align properly. A small axial load, approximately 25 lbf (100 N), may be applied to the specimen by means of the loading device to properly seat the bearing parts of the apparatus.

- Apply axial load continuously and without shock until the load becomes constant, reduces, or a predetermined amount of strain is achieved. Apply the load in such a manner as to produce either a stress rate or a strain rate as constant as feasible throughout the test. Do not permit the stress rate or strain rate at any given time to deviate by more than 10 percent from that selected. The stress rate or strain rate selected should be that which produces failure in a test time between 2 and 15 minutes. The selected stress rate or strain rate for a given type shall be adhered to for all tests in a given series of investigation. Record the maximum load sustained by the specimen.