Table of Contents

Air or Steam (Anaconda Type) Hoist

This is a rugged, compact and efficient hoist applicable for use with either steam or air for surface prospects or underground work in larger mines.

It is a simple machine with few wearing parts; “V” friction clutch. Air requirements 125 to 150 c.f.m.

Beebe Hand Hoist

This unit easily handles a multitude of hoisting problems. It is easily portable and the large gear reduction makes minimum effort required to lift large loads. An ideal unit for trucks, hand derricks, gin poles, jib cranes and similar applications. Power may be applied to any size unit when desired.

Mine Hoist

One of the main problems in the operation of a mine is the hoisting of ores speedily and without excessive labor costs. Mine Hoists are of rugged construction and time proven design and successfully solve this problem. They keep tonnage moving, without shutdowns or delays which reduces overall operating expense. Frames are sectionalized and of heavy steel construction. Drums and gears are of Meehanite and pinions of forged steel. Heavy duty ball bearings, removable and adjustable, are used on the sizes shown. Post brakes are constructed of heavy cast steel and designed with a large safety factor.

Larger sizes of hoists than those listed can be furnished, as well as hoists with different specifications such as drum friction clutches, band brakes, or double drum.

Additional data gladly furnished upon request.

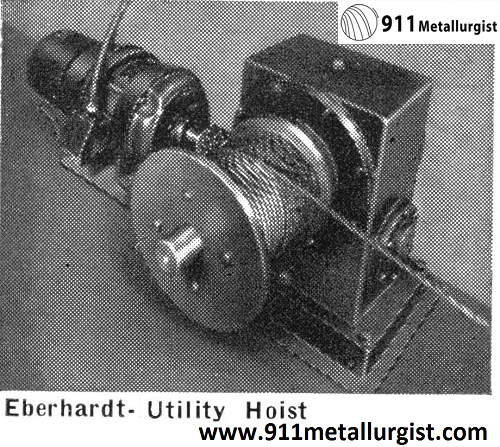

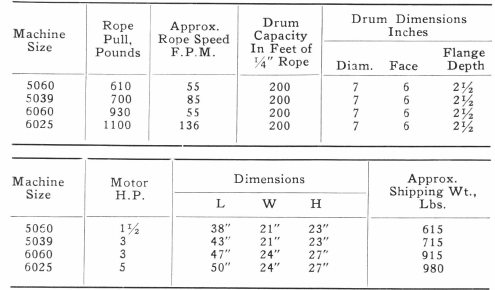

Eberhardt Utility Hoist

The Eberhardt Hoist is a small, substantial and simple electric hoist which may be installed any place, indoors or out, and operated by anyone. This hoist requires no attention after it is installed except for oiling about twice a year, yet it is always ready for use. It is built for required rope pulls up to 1100 pounds.

The following are a few of its many useful applications; lifting and lowering liners when relining a ball mill or rod mill; hauling grinding rods, mine timbers, rails and ties; spotting mine cars, and for hoisting or lowering of light loads.

The hoist consists of a high torque (fully-enclosed if used outdoors) electric motor, direct-coupled to a worm gear speed reducer, all mounted on a welded steel base. A machine-finished drum is mounted on the output shaft of the reducer. The worm in the reducer is machined integral with the shaft and is case hardened, accurately ground and polished. Gears are cut from high-grade gear bronze. Both the worm and gear shafts are mounted on oversize antifriction bearings.

The hoist can be operated by one man from a remote station using a “start-stop-reverse” push button and a reversing magnetic starting switch which is provided with overload relays and low voltage protection. The load is held automatically by a brake on motor armature shaft.

Utility Hoist and Tugger

The hoists illustrated are two of a large variety available for underground duties. The single drum air hoist is extremely useful for such purposes as operating a skip in a winze or for pulling cars on an incline. This hoist can be equipped with column mounting and can be readily installed for the service required. It operates under 30 lbs. per square inch air pressure.

The double drum electric hoist is most suitable, where power is available, for use in connection with scraper mucking and loading, or “slushing” operations. It is also furnished in single and triple drum types and can be driven with electric motor, air motor, gasoline engine or oil engine drive. Capacities range from 750 lbs. to 10,000 lbs. with rope speeds varying from 75 feet to 450 feet per minute on various sizes available.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.