Table of Contents

Spiral Classifier

In mineral processing, the Akins AKA spiral or screw Classifier has been successfully used for so many years that most mill operators are familiar with its principle and operation. This classifier embodies the simplest design, smallest number of wearing parts, and an absence of surge in the overflow. It separates coarse and fine solids, carried in liquids, with a high degree of accuracy and with lowest possible power and maintenance costs. Additional information on Akins Classifiers will be sent upon request.

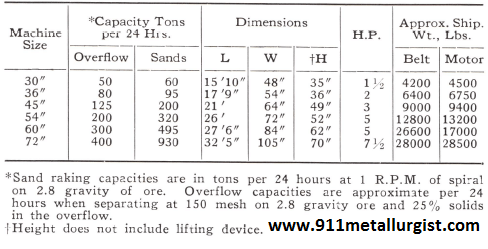

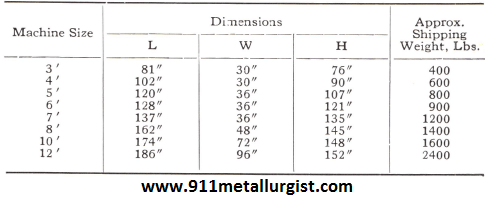

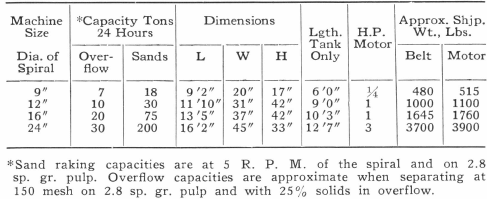

Screw/Spiral Classifier Capacity Table

Allen Cone Classifier

ALLEN Sand Cones and Allen Slime Cones have application in ore-dressing, chemical and industrial processes for classification, dewatering, de-sliming, leaching and washing.

If the pulp (solids and liquid) contains more than 5% of solids larger than 48 mesh, the type 40 Allen Sand Cone is almost always used, where as if the solids contain less than 5% coarser than 48 mesh it is generally advisable to install the type 50 Slime Cone.

The feed enters the cone through an inner truncated cone, settled solids gradually building up in the cone to a point restricting the out-flow of the inner truncated cone. This causes the water level in the truncated cone to rise lifting a float which operates a series of levers to operate a ball valve to open a spigot in the bottom of the cone which discharges the settled material. This arrangement maintains an even depth of sand regardless of increase or decrease in the feed rate. If a foreign object should obstruct the opening retarding the flow the valve opens wider, thus allowing the passage of the obstruction.

The operation of the Allen Slime Cone follows the same general principle as described above except the float is located near the bottom of the cone and is operated by the buoyancy of the settled slime. The float operates a ball valve and spigot same as for the sand cone.

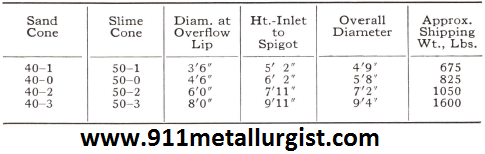

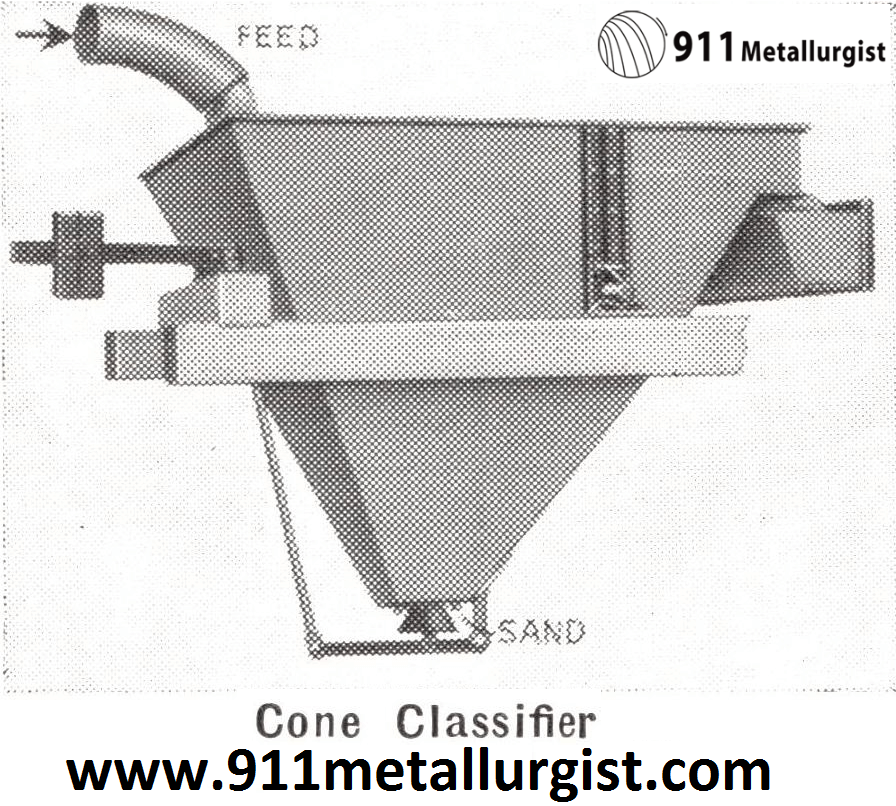

Cone or Pyramid Classifier

CONE Classifiers are built in two types, one operating on the density of the pulp in the cone, and the other on the hydraulic or mechanical movement of the pulp. The Dewatering Cone is of the former type. The weight of the pulp in the cone actuates a lever with an adjusting weight, automatically controlling the discharge valve. This method gives a constant density discharge. The unit can be used as either a dewaterer or classifier, requires no power, and is entirely automatic.

The body of the separator can be conical or pyramidal in shape, to suit best the physical requirements of the location. The classifier can be used to advantage in dewatering and controlling feed to a regrind ball or rod mill, or material from tables, jigs, or flotation.

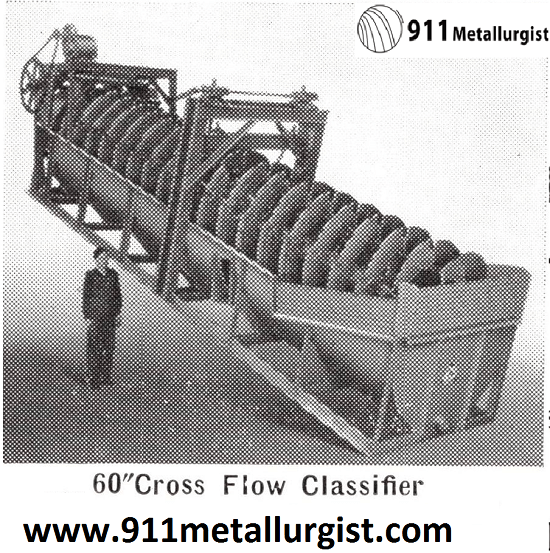

Cross-Flow Classifier

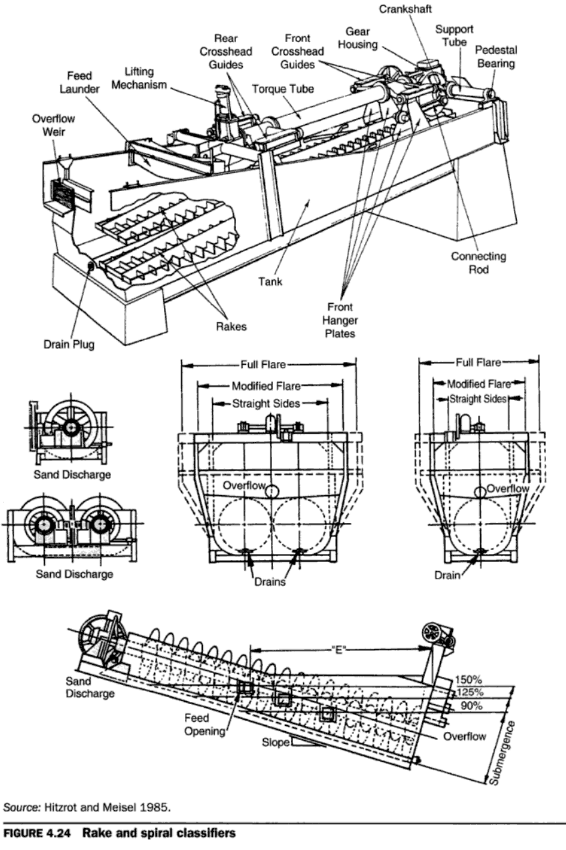

CLASSIFIERS having a helical (often improperly called “spiral”) flight for removing settled coarse material have long been in successful use and most mill operators are familiar with their operation. The Cross-Flow Classifier is of this general type but has many improvements which result in improved metallurgical efficiency, longer life and less repair. Among these improvements may be mentioned:

- The lower bearing has been moved up along the conveyor shaft to a point above the pulp level, thus eliminating the wear and repair which formerly resulted from sand getting into the bearing when it was submerged.

- The location of the main overflow weir is along the side of the classifier opposite the feed, resulting in free and uninterrupted straight line surface flow from the feed entrance to the overflow weir. The conveyor flight moves downward in front of the weir and the submerged portion of the flight moves away from the weir. Thus there is a continual separation and movement of fines toward the weir while coarse material moves away from the weir. The settled material is continually rabbled by the flight and settled fines set free. This arrangement of feed, overflow and direction of rotation of the conveyor flight results in a minimum of oversize in the overflow and a minimum of undersize in the sand discharge. This is improved metallurgical efficiency.

An auxiliary weir is provided at the end of the classifier. Both the main and auxiliary weirs are provided with weir blocks by which the depth of the pulp and pool area may be adjusted, thus controlling the size of separation.

The Cross-Flow Classifier is ruggedly constructed and the tank is thoroughly reinforced. Bearings are Jarge and all gears are enclosed. The 6″, 9″, and 12″ sizes have replaceable hard cast iron flight sections on a square shaft. The 18″, 24″, and 30″ have replaceable hard cast iron flight sections. The 36″, 42″, 48″, 54″, and 60″ sizes have replaceable steel flights and replaceable hard iron wearing shoes. Sizes 30″ and larger are provided with lifting device by which the lower end of the flight may be raised and the conveyor operated while it is slowly lowered, thus gradually removing the bed of solids which settles during a shutdown.

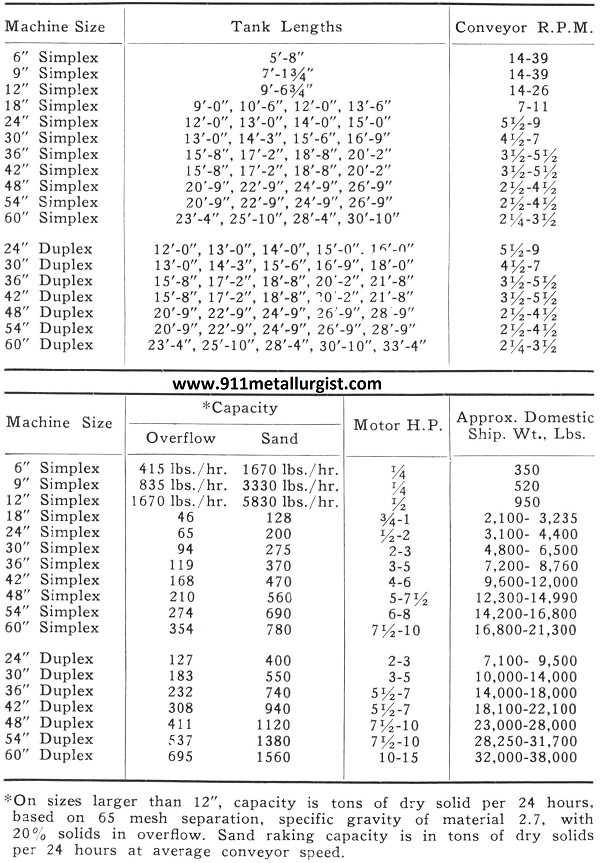

Spiral-Screw Classifier Capacity Table

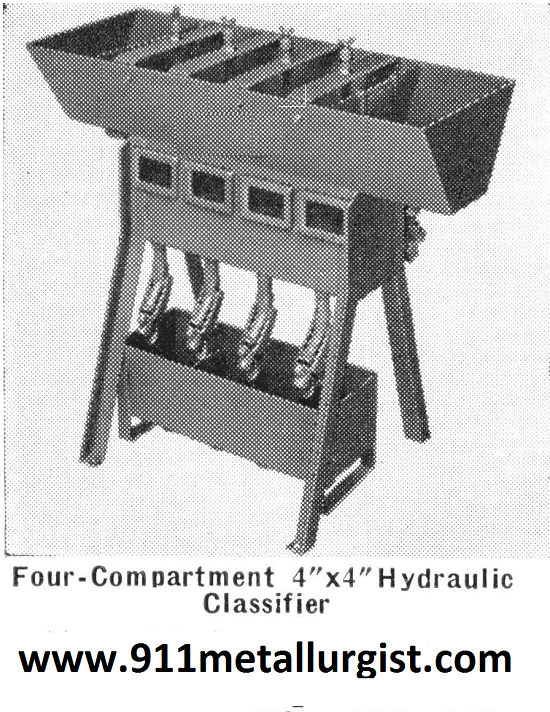

Hydraulic Classifier

Hydraulic Classifier is designed for use in gravity concentration mills for pre¬paring a classified feed for table concentration.

The classifier compartments are provided with glass sides so that the conditions existing in each chamber can readily be observed. Only enough water is necessary to keep the solids in full teeter. As the sands accumulate in the classifier pockets the effective density of sand-water mixture increases and thumbscrews on the valve rod assemblies may be adjusted to discharge sand from each compartment as required. The finer the sand the less water is required. When the pressure regulating valves and the product valves are set, no further adjustment is necessary.

The compartments are so arranged that the perforated constriction plates for the coarser feed are nearer the feed end with each succeeding compartment arranged for a smaller mesh product.

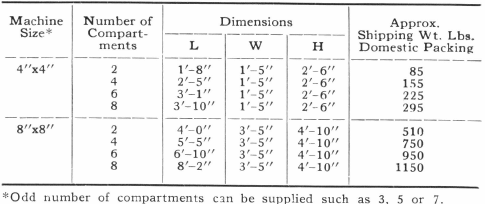

The Hydraulic Classifier is made in 2, 4, 6, and 8 compartments with two sizes of compartments, namely 4″x 4″ and 8″x 8″. The standard units are of steel construction. Capacity depends on specific gravity of the material and range of size taken from each compartment.

The 4″x 4″ has a capacity from 5 to 10 tons per compartment in 24 hours.

The 8″x 8″ has a capacity from 20 to 50 tons per compartment in 24 hours.

Additional data gladly furnished upon request.

Hydro-classifier

The Hydroclassifier is designed to make a separation according to size in the range from 100 mesh to that of colloidal particles. It is particularly suited to the removal of slimes prior to further treatment by flotation, cyanidation, or chemical processes. The separation in this fine size range requires a large quiet, pool area, such as is provided by the Hydroclassifier, combined with accurate control over the removal and washing of the settled material for maximum classification efficiency.

In the Hydroclassifier the feed enters a feed well in the center of a large settling tank and flows without agitation into the pool. The slimes and fine material move radially to the overflow weir at the rim of the tank and overflow into the overflow launder. As the slimes move to the weir, the coarse particles settle on the sloping tank bottom, where slowly moving spiral rakes continuously move these settled solids to a central discharge cone. In the discharge cone water is added below a perforated plate while the settled solids are rabbled above the plate, thoroughly washing out slimes and fines from the coarse material, as it works through the openings in the plate. The coarse material is usually removed in the form of a sludge by means of a Adjustable Stroke Diaphragm Pump.

Accurate control is maintained by:

- Control of the wash water added to discharge cone.

- Control of the rate of removal of settled solids by means of the diaphragm pump.

The tank is steel, thoroughly reinforced, and supported on steel columns, thoroughly braced. The mechanism driving the rakes is an alloy steel gear and bronze worm, supported on anti-friction bearings enclosed and running in oil. The vertical shaft and rakes may be raised or lowered while the mechanism is in operation. Extra heavy construction is provided throughout, resulting in long life and a minimum of repair.

Additional data gladly furnished upon request.

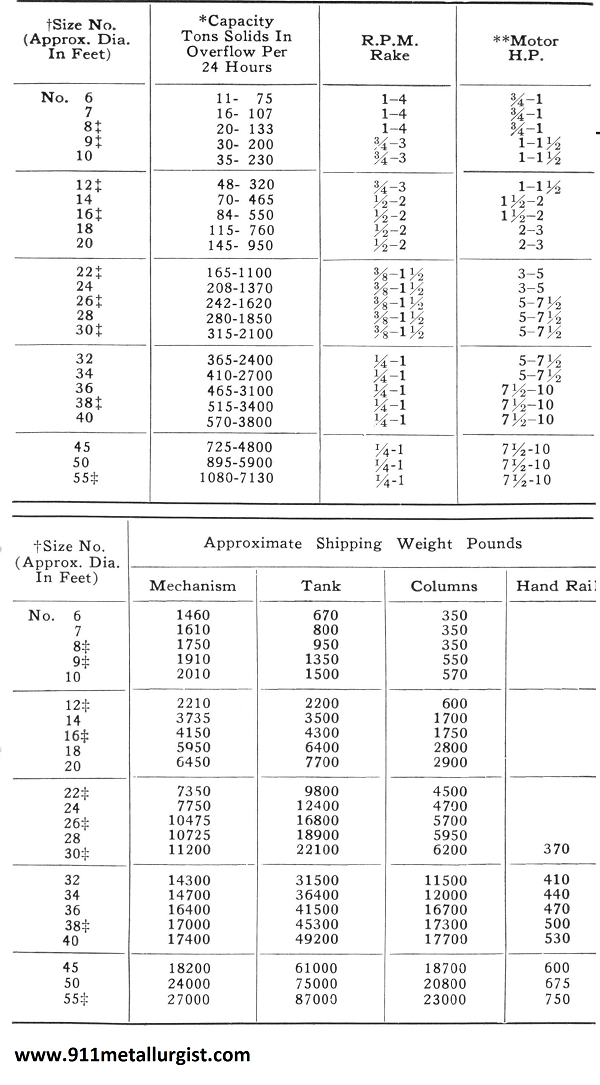

Hydroclassifier Capacity Table

In addition to these standard machines we can furnish larger sizes where mechanism is placed in customer’s concrete tanks. Mechanism sizes 22 to 40 can be furnished for concrete tanks.

These sizes can be furnished in Bolted Steel Tanks.

Capacity range depending on mesh separation, specific gravity and per cent solids in products.

Horsepower depends on the amount of solids settling and specific gravity.

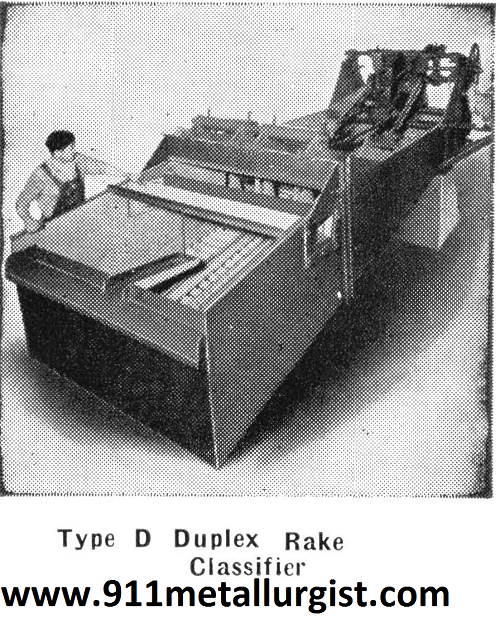

Rake Classifier

The Rake Classifier is designed for either open or closed circuit operation. It is made in two types, type “C” for light duty and type “D” for heavy duty. The mechanism and tank of both units are of sturdiest construction to meet the need for 24 hour a day service. Both type “C” and type “D” Rake Classifiers have a tank made of heavy steel plate with the seams double electric welded both inside and out. Tanks are arranged so that feed may enter from either side. Rakes are made either of heavy steel angles welded to channel supports which are carried by the actuating mechanism or channel irons split lengthwise and welded to supports, whichever type of duty the classifier will be expected to perform. Raking movement is accomplished by a cam and roller drive. Cams are mounted on an oversize shaft and driven by a semi-steel cast tooth gear and pinion on the light duty unit or heavy molychrome steel cams operated by machine cut gears are used on the heavy duty unit. Mechanism supports are of the strongest possible construction and have a large safety factor to withstand severe load conditions. Also, the babbitted pillow block drive bearings on the light duty unit and the bronze bushed drive bearings on the heavy duty unit are of ample size to handle most any overload condition.

A rake lifting device, utilizing worm gears, a hand crank, and steel cables, is provided on both units and this rake lifting device is so designed that one man can quickly and easily raise or lower the rake. Classifiers can be furnished either belt or motor driven. On the belt driven type a right angle drive can be supplied if desired. The standard motor drive is V to flat with 3-phase, 60 and 50 cycle, 220, 440 or 550 volt motor.

The standard length of “C” type simplex classifier is 14’8″, with widths of 1’6″, 2’0″, 2’3″, 3’0″. Type “C” duplex standard lengths are 12’0″, 14’8″, 16’4″ and 18’0″, with widths of 4’0″, 4’6″, 5’0″ and 6’0″. Model “D” simplex has tank lengths of 18’4″, 20,0″, 21’8″, 23’4″, 25’0″, or 26’8″, with width of 3’0″ and 4’0″. Heavy duty model “D” duplex comes with tank lengths the same as model “D” simplex, and widths of 5’0″, 6’0″, 7’0″ and 8’0″.

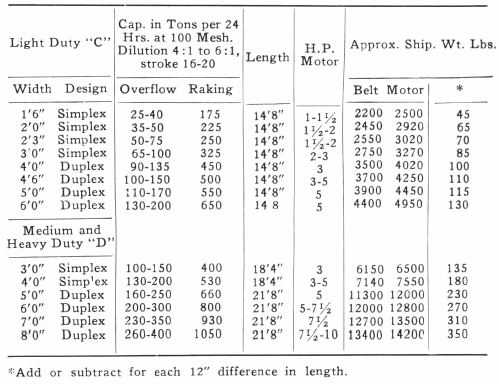

Rake Classifier Capacity

Rotary High Weir Classifier

The Rotary High Weir Classifier is designed to give best classification of fine and coarse material. The horsepower is low and maintenance is reduced to a minimum. The classifier is made with either a high or low weir, the high weir with its larger pool area being used where a fine separation is necessary. Rotary High Weir Classifier is built with replaceable wearing flights, steel tank mounted on base, and belt or gear-motor drive. Standard drive is a single bevel gear, although spur gear and double reduction drive units can be furnished.

The two conveyor shaft bearings are mounted outside of the tank away from pulp and splash. The conveyor shaft is effectively sealed at the slime overflow end of the tank by means of a specially designed stuffing box which contains a distributing ring in addition to the conventional packing rings. Admission of water to the interior of the stuffing box prevents any dirt from entering.

This classifier can also be made of corrosion-resisting material so as to handle successfully products such as sulphuric acid.

Rotary High Weir Classifier Capacity

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.