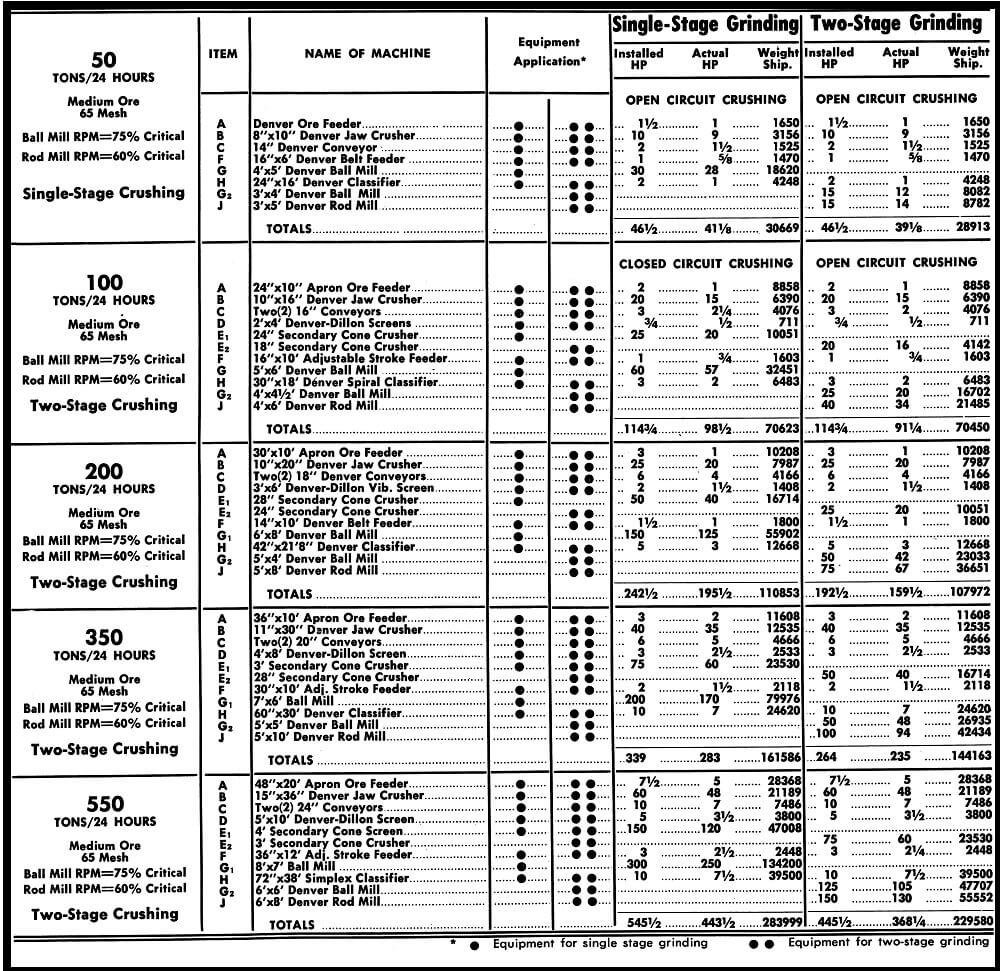

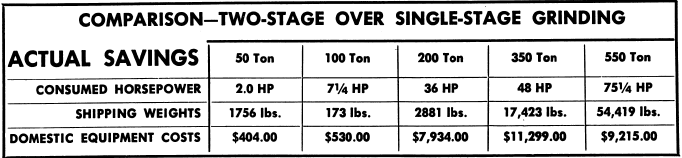

The comparison between single stage and double stage grinding has received much attention in the past few years. In order to submit information for use of mill operators, we have prepared comparative flowsheets for 50 Ton, 100 Ton, 200 Ton, 350 Ton and 550 Ton/24 hour plants, showing both single and two-stage grinding in typical mill flowsheets. These flowsheet comparisons show the benefits on the basis of connected horsepower, actual horsepower, shipping weight and factory price.

The following tables are for wet grinding. Comparison of capacities is based on approximately the cube of the diameter times the length. Capacities for dry grinding are 60-75% of those shown for wet grinding.

As indicated by this information, two-stage grinding gives definite advantages resulting in lower actual consumed horsepower, shipping weight and first cost of equipment. Naturally, with the same horsepower for both single and two-stage grinding you will get a greater tonnage with two-stage grinding and less sliming and oxidation of the mineral. Generally, in fine grinding, the fewer slimes produced, the greater the recovery that can be made by any concentration method. It also has the advantage of a simplified crushing section, in that a coarser crusher product can be readily handled by the rod mill. The secondary crusher making a coarse product can then often pass drill bits. It costs less to increase the grinding capacity of the mill by adding a rod mill to provide two-stage grinding, rather than by replacing the ball mill with one of larger size.

TWO-STAGE GRINDING CIRCUITS readily allow for the advantageous use of a Mineral Jig or a Unit Flotation Cell to recover coarse freed minerals as soon as they come from the grinding mills. There is a marked advantage in maintenance by having the ball mill and rod mill of same diameter as shown in the above table for interchangeability of parts.

The advantage of flexibility and using one or the other of the two mills during a period of reduced mill tonnage is considerable in the two stage grinding systems.

Closed circuit crushing is recommended for single stage grinding as there is greater control over size of feed going to the one ball mill.

Open circuit crushing is advantageous when using two-stage grinding due to the ability of the rod mill to handle an over-size feed product.

To obtain 2016 pricing, please multiple all dollar values by 8 to 10 X

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.