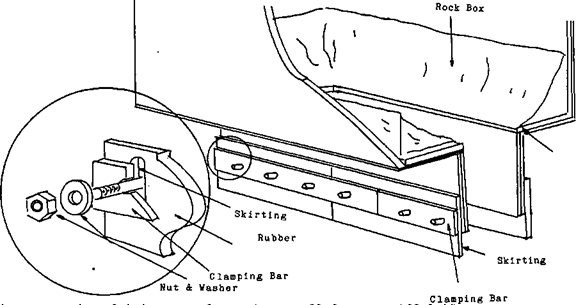

The transfer chute skirting is made from rubber and prevents rock from bouncing and rolling over the edge of the conveyor when it is loaded onto the belt. This skirt runs completely around the chute except for the discharge point at the front. As the skirt and the belt cannot have a lubrication put on them this is an area of high wear. Because it is an area of high wear the operator will have to monitor its condition constantly adjusting the worn portions as required. The adjustment of skirting takes a little practice, too little and spillage will result, too much and the skirting will wear out very quickly. In some cases skirting that is adjusted too tightly will overload the conveyor drive motor causing it to kick out.

The transfer chute skirting is made from rubber and prevents rock from bouncing and rolling over the edge of the conveyor when it is loaded onto the belt. This skirt runs completely around the chute except for the discharge point at the front. As the skirt and the belt cannot have a lubrication put on them this is an area of high wear. Because it is an area of high wear the operator will have to monitor its condition constantly adjusting the worn portions as required. The adjustment of skirting takes a little practice, too little and spillage will result, too much and the skirting will wear out very quickly. In some cases skirting that is adjusted too tightly will overload the conveyor drive motor causing it to kick out.

When there is a large volume of ore going through a conveyor system, any lost time that is caused by equipment failure, plug up or operator error is very serious. The lost tonnage, labor, and repair costs can be very expensive. To help the operator in carrying out his duties and to keep his down time to minimum, certain safeguards have been incorporated into the system.