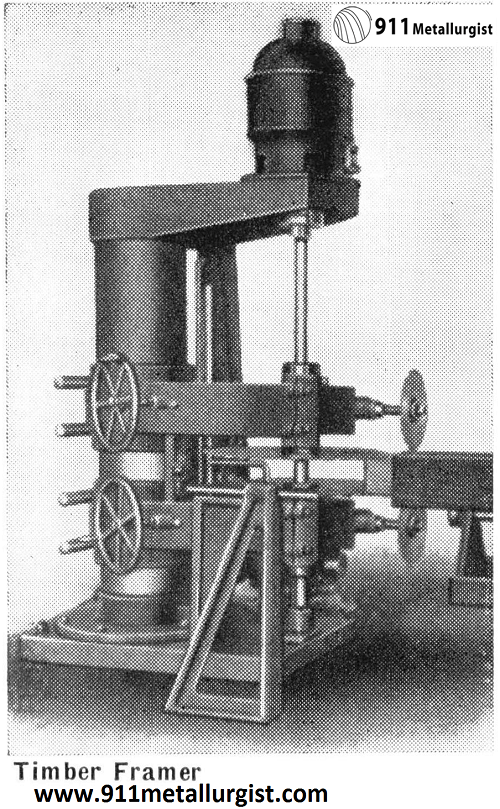

Timber Framer is a necessary piece of equipment for any mine using considerable mine timbers. Framing timbers by hand has become obsolete at larger properties since the development of this economical and efficient machine.

In operation a log is placed in the chucks and pushed through the saws; the chucks are then thrown over ninety degrees and the log is pulled back through the saws, thus framing one end. The carriage is then revolved 180° by means of the ball bearing turntable and the operation is repeated on the other end of the log. All adjustments are made to scales built in and can be made while running.

The Timber Framer consists of a head frame comprised of a rigid horizontal cross arm at the top of a vertical extra heavy steel column mounted on a heavy cast iron base. The rigid horizontal cross arm at the top of the column supports the driving motor and shaft for the rip saws for horizontal cuts. Two separate cast iron arms on the column support the individual driving motors and the cross cut saws which make the vertical cuts. Arms are adjustable vertically by means of handwheels. A structural steel gauge stand and a timber carriage with a steel ball supported turntable mounted on a truck running on rails is also supplied.

The machine is equipped with saws, belts, counter-shaft, etc. The Timber Framer will handle logs as large as 30 inches in diameter and 10 feet long. The unit requires a space 12 feet long by 12 feet wide and 10 feet high. The shipping weight is 7,000 pounds and total required horsepower is 30.