The objectives of thickener control are varied, but in most instances, the objective is to dewater the slurry, reclaim the clear overflow for reuse in the process, and produce a thickened or more dense underflow, which can either be rejected, in the case of tailings, or used as feed for subsequent unit operations.

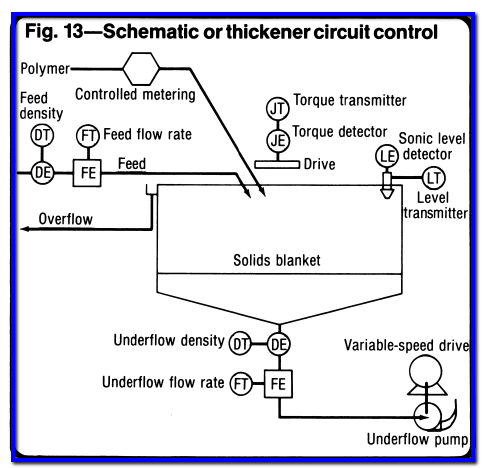

The general Process Control Strategy for a thickener are shown in Fig. 13. By knowing the feed density, feed flow rate, underflow density, and underflow flow rate, the solids in, solids out, and solids inventory in the thickener can be maintained by adjusting the pump speed. Overrides, or limits, to the controlled variables are underflow density, drive torque, and solids inventory level. If the flow out is less than the flow in, the pump speed will not increase unless the density is such that the drive-torque upper limit or the maximum solids inventory has been reached. If the flow out is greater than the flow in and the outflow density is lower than desired, the pump speed will be decreased, provided the drive-torque limit is within a safe operating range and the solids inventory is below the upper limit. The polymer feed rate will be controlled by using a variable-speed calibrated metering pump based on the solids and volume in the feed.

This thickener system would be difficult to control automatically with analog instruments and controllers, because of the decisions that are required. It could be operated with good stability by using a computer-based controller that included the necessary limiting logic.