Table of Contents

Bolted Steel Tank

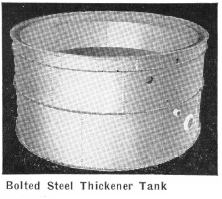

The Bolted Steel Tank has proved extremely valuable in mining and milling operations. The special design and construction features of this tank, which allow field bolting, give great strength, insure long life, and yet maintain light weight, make it particularly adaptable to all mining users. It is used for ore bins, solution or water storage, and for agitators, conditioners, and thickeners. The fact that it is built in sections and packed knocked down simplifies fabrication and it can be easily set up by ordinary workmen. This tank is very economical because it can be enlarged, or made smaller, or a damaged section replaced without difficulty. There is no loss with the bolted steel tank as it can be quickly dismantled and moved to another site.

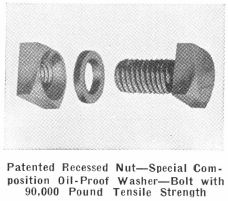

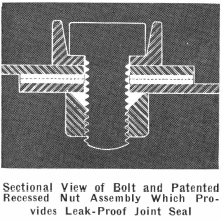

Bolted Steel Tank is formed and punched so that it fits perfectly. The patented, leak-proof nut insures a water-tight joint; the nuts are recessed with special, oil-proof gaskets (as shown in the illustration at left) which stop any possibility of leaks around bolt threads.

These tanks are ideal for use in any locality and are particularly desirable for use in tropical or semi-tropical countries where deterioration of other types of tanks may be very rapid. No matter what your application or where your plant is located, the use of these tanks should be considered as mass production and standardization have allowed considerable reduction in the prices.

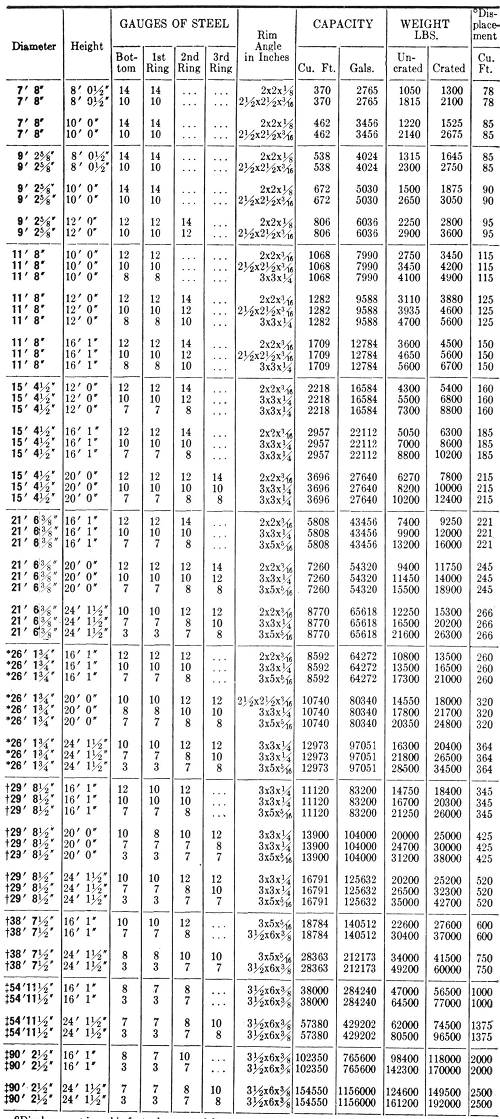

While the diameters listed are standard, Bolted Steel Tanks can be furnished in any height desired. Where the exact volume needed for your requirements is not indicated, use the standard diameter which most closely fits your problem and increase the height to give necessary capacity.

Tank Capacity

Welded Steel Tank

Modern methods of manufacture have made the welded steel tank not only practical but in many instances more economical than any other type of tank. The Welded Steel Tank is extensively used in the mining, processing, and industrial fields and is ideal for the agitating, conditioning, or thickening of heavy liquids or pulps.

Welded Steel Tanks are being used more and more extensively in the smaller sizes and particularly wherever the fluid line varies considerably. The larger sizes of Welded Steel Tanks are used in many locations where field erection can be undertaken, the site is relatively permanent, and salvage is not a primary consideration.

Standard Welded Steel Tanks are made with heavy, double-welded construction. The side and bottom plates are of heavier metal than normally supplied and added strength is also secured by an angle iron rim. All standard tanks are sufficiently strong to stand the weight of the superstructure, rotating mechanisms, or flooring ordinarily used in metallurgical, processing, or other industrial plants.

Tanks ten feet in diameter and smaller can be shipped completely erected on a standard railway car while tanks larger than ten feet in diameter can be furnished either for field riveting or welding, whichever may be desired or most practical.

If the standard tanks listed here do not meet the requirements for your installation, tanks can be engineered to meet your particular needs. Let us make recommendations for the type and capacity of tanks best suited to your plant when taking into consideration the properties of the material to be stored or treated, cost, location, and climatic conditions.

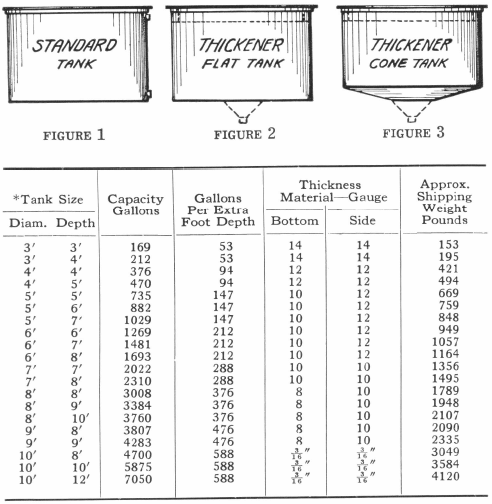

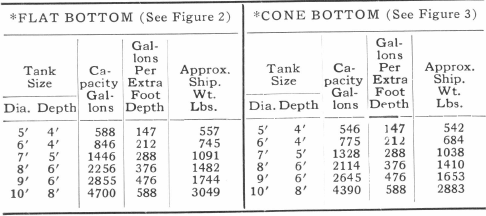

Data given is for standard Welded Steel Tanks (see Figure 1) with flat bottom, heavy welded construction, and angle iron rim. Diameters of steel tanks are measured on inside.

Small size Welded Steel Thickener Tanks with steel overflow launders.

Small size Welded Steel Thickener Tanks with steel overflow launders.

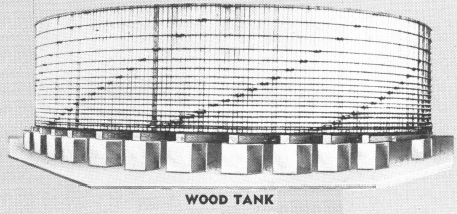

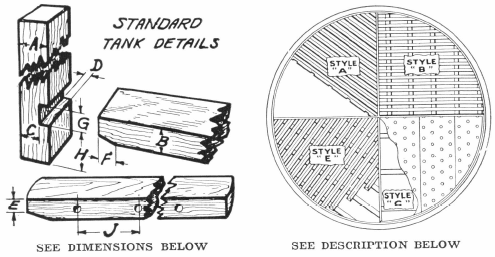

Wood Tank

The Wood Tank is made of selected Douglas Fir, Redwood, Yellow Pine, or Cypress, whichever is best adapted to your particular problem. For example, where unusual climatic conditions occur, as in tropical and semi- tropical countries, special red¬wood creosoted tanks are preferable. Wood Tanks are made from the finest quality lumber, treated in kilns to retain the life of the wood and add to its strength and durability. Staves are milled to the true circular outline of the tank, and edges dressed smooth to radial lines. This insures ease of erection and, when equipped with the proper number of hoops and lugs, a uniform distribution of stresses when handling high specific gravity materials.

The sides of the tanks are made straight, without taper, unless otherwise specified, and are beveled to fit the proper diameter, insuring water-tight joints. Sufficient round hoops and lugs of proper size are furnished to take care of pulps or solutions of any specific gravity.

More complete information can be obtained by writing any Equipment Company office.

FALSE AND FILTER BOTTOMS FOR TANKS

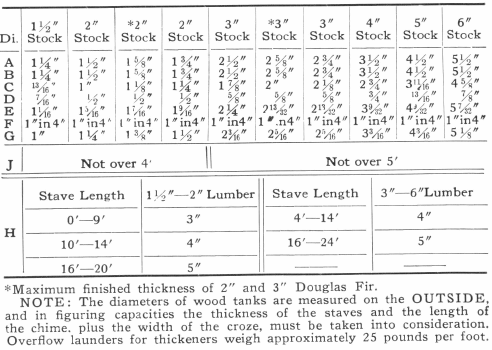

STYLE A: Bottom consists of grating of crozed strips 1¼”x 1¾” Douglas Fir laid on edge 1¼” apart. Filter cloth protected by thin wood band 3/8″ thick placed around outer edge of these strips.

STYLE B: Bottom consists of grating of crozed strips 1¼”x 1¾” Douglas Fir laid on edge and placed 2′ centers. On bottom strips is placed a grating made of 7/8″x 7/8″ Douglas Fir strips spaced 1″ apart, a thin wood band 3/8″ thick is placed around outer edge of strips.

STYLE C: Bottom constructed of 1″ Douglas Fir floor, provided with ½” holes approximately 2″ apart, and supported by croze strips.

STYLE E: Bottom does not require filter cloth. It consists of triangular strips about 3″x 3″x 3″, spaced ¼” apart and resting on crozed strips 1¼”x 1¾” Douglas Fir, laid on edge 2′ centers. Spaces between triangular strips are filled with gravel, sand and quartz, level with the upper edge.

Bolted or welded steel tanks and wood tanks (Douglas Fir, Redwood, Cypress or Pine) are available for general use, or in rubber-lined steel or acidproof alloy construction for acid or corrosive applications. Get our low prices on field welded steel tanks. Let give you estimates on any of your tank requirements, especially for acid or corrosive solutions.