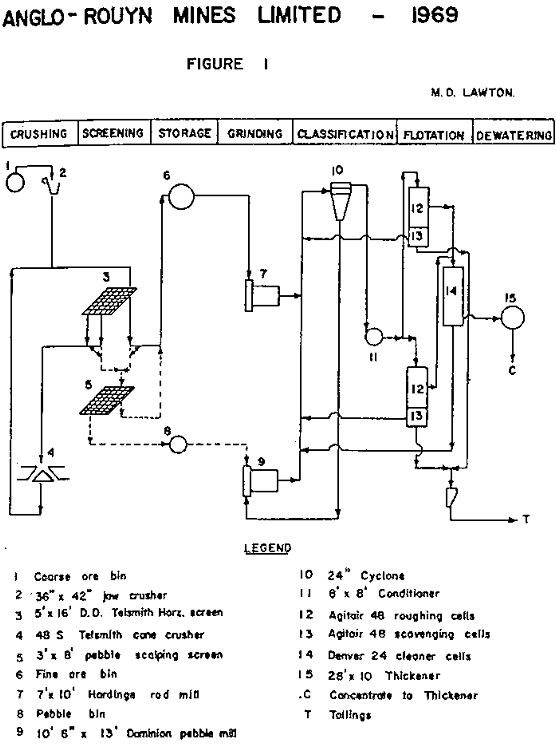

The crushing section was designed to supply approximately 100 tons per hour of -5/8 in. material to the Fine Ore Bin. Early milling results indicated that the ore was somewhat harder than expected and the 7 ft. x 10 ft. Hardinge Rod Mill was proving to be a bottleneck.

The comparatively wet ore, sizing up to 14 in., is fed from underground to a 36 in. x 42 in. Buchanan Jaw Crusher, crushing to approximately -6 in. size. This feed passes to a 16 ft. x 5 ft. Double-deck Horizontal Telsmith screen.

It was mentioned earlier that there had been a bottleneck in the rod mill with the underflow from the 1½ in. x 5/8 in. screens therefore all three 4 ft. lengths were changed to 1½ in. x ½ in. In addition it was suggested that the orientation of the slots be changed to “across-the-flow” as we were experiencing a lot of blinding possibly due to both the shape of the feed and the dampness of the ore.

These changes, however, lowered the crushing rate to approximately 70 tons per hour, increased the circulating load of rock both above and below the 2 in. size and gave excessive ammeter readings on the crushing motor.

The excessive blinding of the screen-cloths was still a problem and measurements indicated that at least 20% of the circulating load from the screen to the cone crusher was already fine enough to pass through the 1½ in. x ½ in. screens. To maintain a reasonable throughput it was necessary to clean the cloths every 2 hours.

Various hole diameters were then tried. Earlier observations had indicated that excessive rock, which had no chance of passing through the lower-deck 1½ in. x ½ in. screens, was being passed through the upper-deck 3½-in. x 1½ in. slots. This oversize rock appeared to be forming a bed that carried undersize rock the full length of the lower screen without giving this undersize material the opportunity of passing through the lower screen. This was presumed to be the reason for the excessive circulating load of undersize rock. A decision was also made to alter the 1½ in. x ½ in. screen orientation by reverting to the standard practice in dry screening, i.e. having the slots parallel to the flow.

The changes in shape, size and configuration improved the performance and we were at this stage, crushing approximately 95 – 100 tons per hour.

Both the grinding and flotation circuits had remained virtually-unchanged from the original plan which had been developed from the pilot plant tests. Recovery percentage of 95 – 96% was satisfactory but it was felt we should try for improvement.

The first major test was to follow a trend that appeared to be gaining favour in flotation plants throughout the world. This involved putting all 20 flotation cells in series, using 10 Roughers and 10 Scavengers instead of two parallel banks having 6 Roughers and 4 Scavengers in each.

We found the series circuit a lot more difficult to control, we had more pumping troubles and more frother was being used. The results indicated that this circuit was no better than the parallel circuit. In some instances it seemed even worse. We decided to revert back to parallel flow.