One of the many responsibilities of mining engineers and mill superintendents is to provide for the safe and economic disposal of wastes (or tailings) remaining after a mineral has been extracted from an ore. The cost of disposal of these tailings exerts a considerable influence on the minimum grade of ore extracted from the mine. It varies to a great extent with each project and is dependent on many diverse factors, such as the local topographical, meteorolgical, geological and seismological conditions together with the applicable water pollution laws of the area.

The liquefaction susceptibility of tailings deposits from a mining or chemical processing operation appears to be increasing, probably because the deposits are being built to greater heights and because the waste materials have a much finer gradation than before. Although there are many indications that mining engineers and mill superintendents are well aware of tailings disposal problems, it is apparent that many of those responsible for the layout and operation of disposal facilities are having difficulty getting rid of an immunity complex. However, this kind of thinking may well lead to disaster. Liquefaction failure is a very real danger in any deposit which has not been carefully planned and properly constructed.

Tailings Disposal

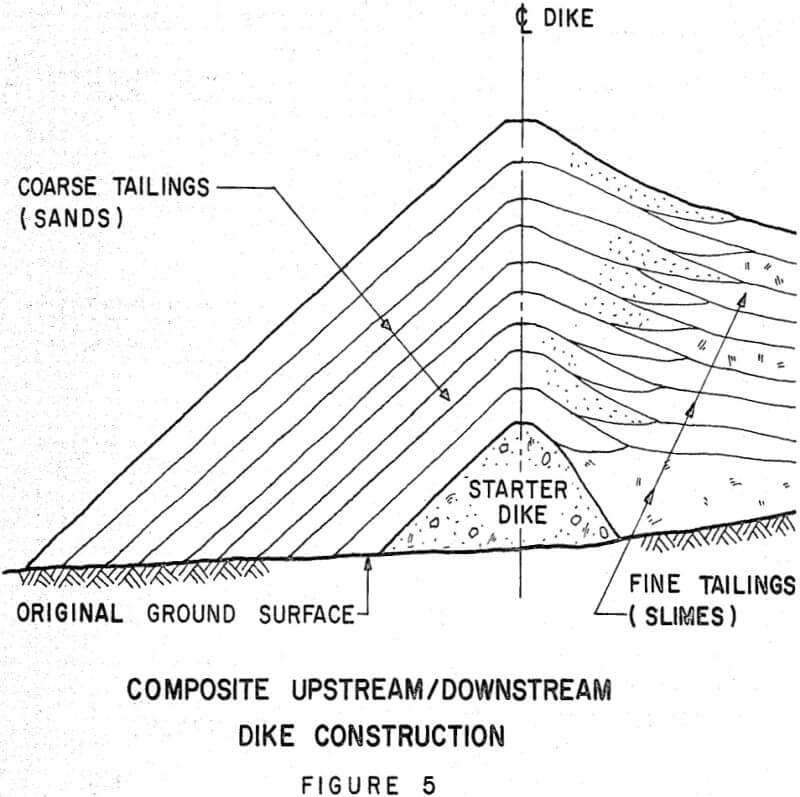

Since the many variations in site conditions, ore bodies and extraction processes dictate the general disposal procedures and mill superintendents incorporate special facilities to provide the most economical disposal method consistent with accepted safety standards, it is only natural that there are almost as many different disposal techniques as there are disposal areas. Methods used in the construction of retaining dikes include:

- transporting granular material from an adjacent borrow pit and

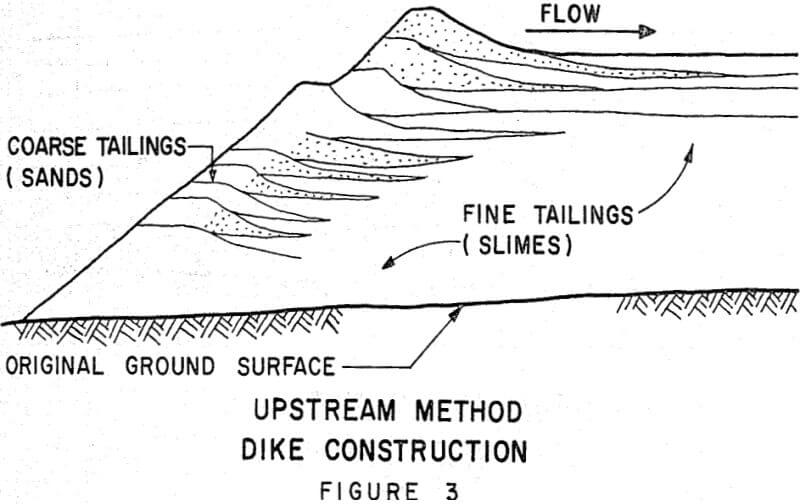

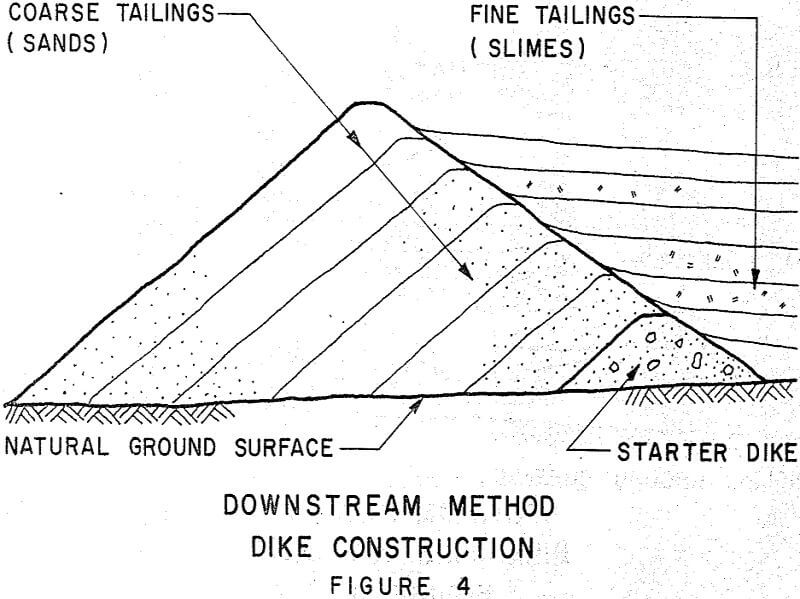

- mechanically segregating the total effluent and allowing the coarse fraction to form a retaining dike by hydraulic deposition.

The location of a plant and the surrounding topography exert the greatest influence on the layout of tailings disposal facilities. Most of the above-ground waste deposits can be classified as side-hill, cross-valley or stockpile deposits. Side-hill disposal areas are probably the most common type of layout because of the natural advantage of gravity flow, without the disadvantage of river diversion usually needed for tailings ponds formed behind cross-valley dikes. Stockpiles, which are placed on relatively level ground, require four retaining dikes and the effluent generally has to be pumped up into the disposal area.

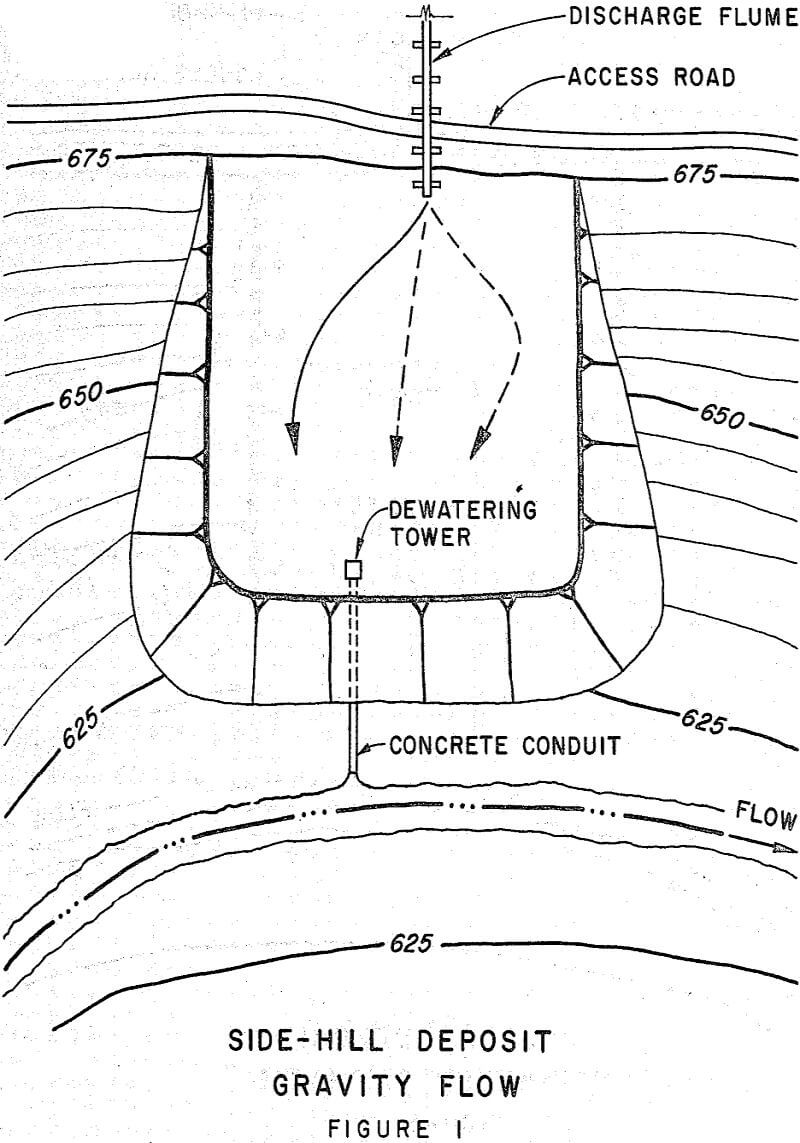

Many of the early side-hill deposits were formed by discharging the effluent at the edge of the hillside and allowing it to flow to the lower part of the pond where a dewatering tower was usually located, just behind the retaining dike.

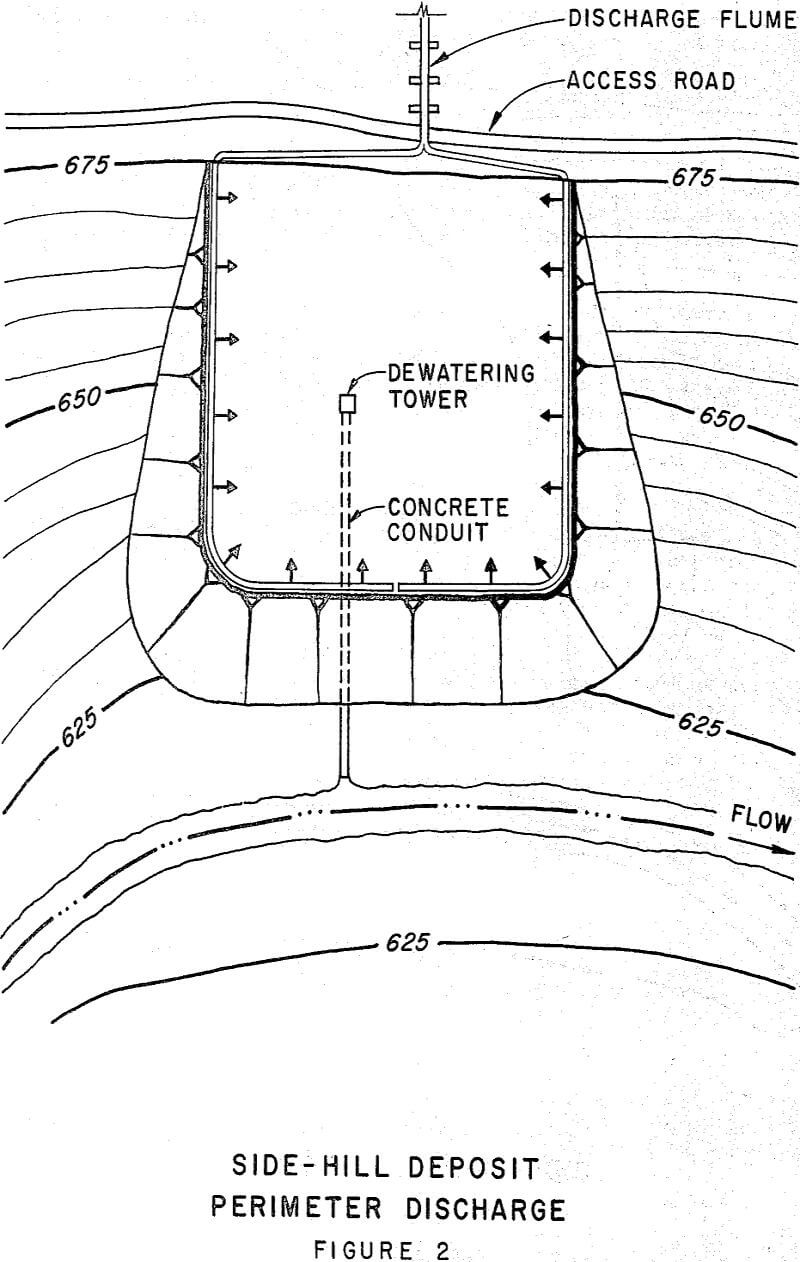

Perimeter discharge with the dewatering chimney located well back from the retaining dike became standard practice for other than special circumstances. Gravity flow of the total effluent resulted in segregation of the slimes from the sands, thus ensuring that only coarse tailings were deposited behind the dike. One of the more recent innovations was the use of cyclones – mechanical centrifugal separators – to classify the tailings.

Liquefied Tailings Deposits

Liquefaction failures of tailings deposits are not all of recent occurrence, but they are now being reported with greater frequency. Probably one of the earliest disasters was the Barahona liquefaction failure in central Chile in December, 1928. After more than 8 years of operation, the disposal area contained about 30 million tons of tailings and the retaining dike had reached a height of just over 200 feet. Great loss of life and extensive property damage occurred when a severe earthquake, centered about 100 miles from the disposal area, destroyed the dike and released 9 million tons of liquefied tailings into the valley below the facilities.

Foundation spreading similar to that in the Fort Peck Dam failure resulted in liquefaction of a tailings deposit near Santander in northern Spain with disastrous consequences. Prior to this particular failure the deposit had been extended, with a portion of the main retaining dike being founded on old tailings. Vegetation had developed over the disused part of the deposit until, eventually, over a period of years it came to be considered as natural ground.

Reduced Liquefaction Susceptibility

The liquefaction susceptibility of tailings deposits is most readily reduced by (1) increasing the in-situ densities and (2) eliminating excess porewater pressures. Mill superintendents are responsible for achieving the minimum requirements of either or both of these in-situ material properties by the most economical method. Sound planning combined with the adoption of relatively inexpensive modifications to disposal techniques in the early stages can prevent problems from arising during later operations. Such problems, if allowed to develop, are usually costly to eliminate.

Because of the almost total unpredictability of the liquefaction phenomenon, it is difficult to design against it without incorporating what appear to be uneconomical features. Eventually, during the “life” of a tailings deposit, a combination of critical circumstances may occur which could result in a liquefaction failure of the deposit. Such an event could be delayed a long time after the disposal area has been abandoned and the land below the dike has been developed, thus making a liquefaction failure much more disastrous.