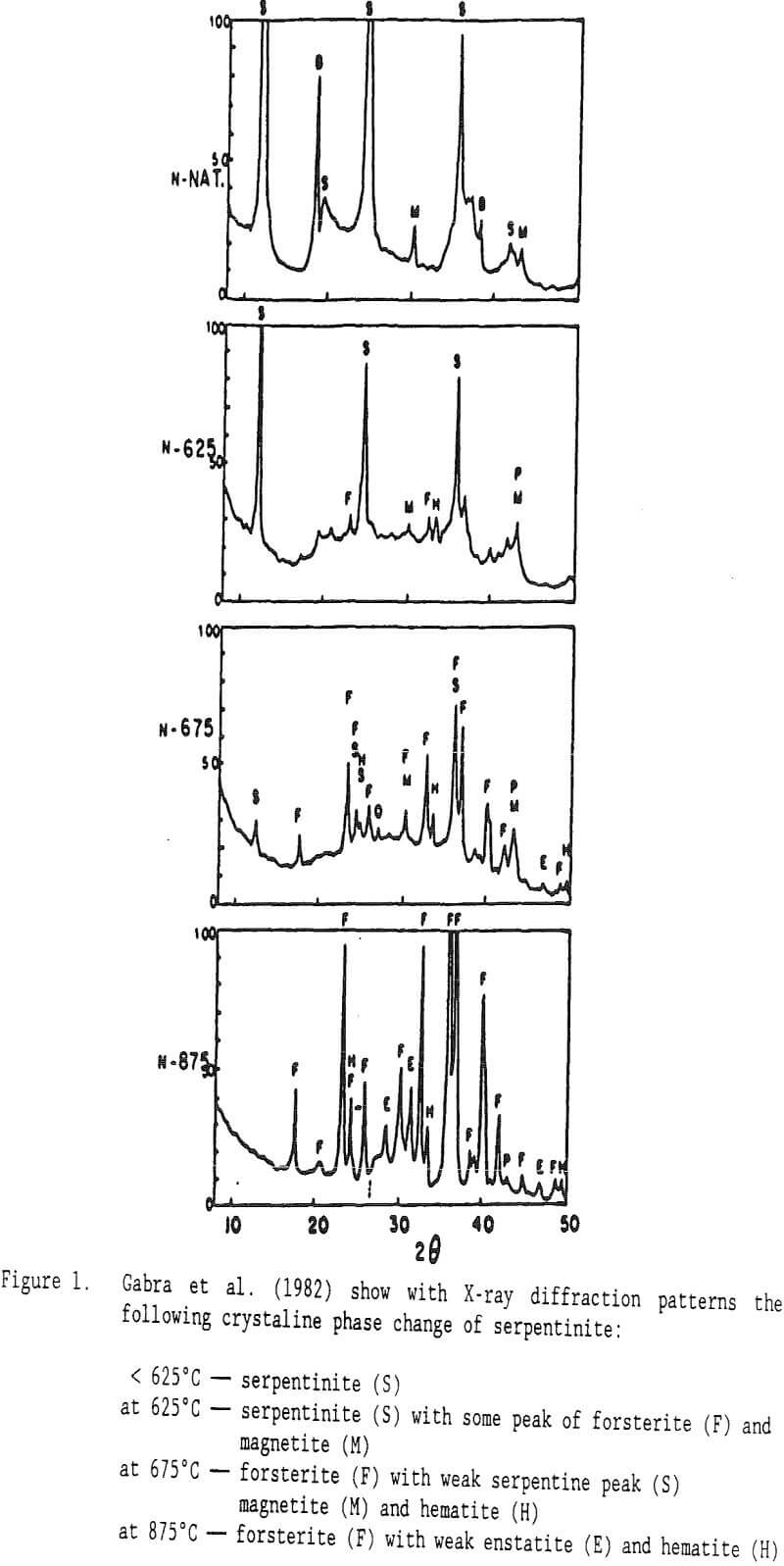

Serpentinite minerals are available in large quantities from asbestos mining activity. The granular or fibrous serpentite, at temperatures greater than 700°C, will recrystalize into olivine, forsterite and enstatite. These minerals have been used and studied for decades and are environmentally safe. The thermal process changes the composition and properties of the original mineral. Therefore, the substitution of the original mineral cannot simply be made and the applications for these new synthetic minerals need to be redeveloped. The two original mineral forms allow a wide range of new synthetic raw materials which can be adjusted to specific applications or custom needs.

Minerals from the serpentinite group have been exploited as an industrial mineral for more than a century. This mineral is a hydrated magnesium silicate Mg3Si2O5(OH)4, which can take a granular or fibrous form. The minerals generally crystalize in the monoclinic system.

Asbestos mining has produced a large source of mined and grinded minerals. Both the granular, and sometimes the short fiber fraction of the fibrous mineral forms, resulting from the exploitation, are stockpiled as a waste product, with little to no commercial value. If these waste minerals are collected from the actual milling operation, special dry mineral granular or fibrous mineral are available with various granulometry of bulk density.

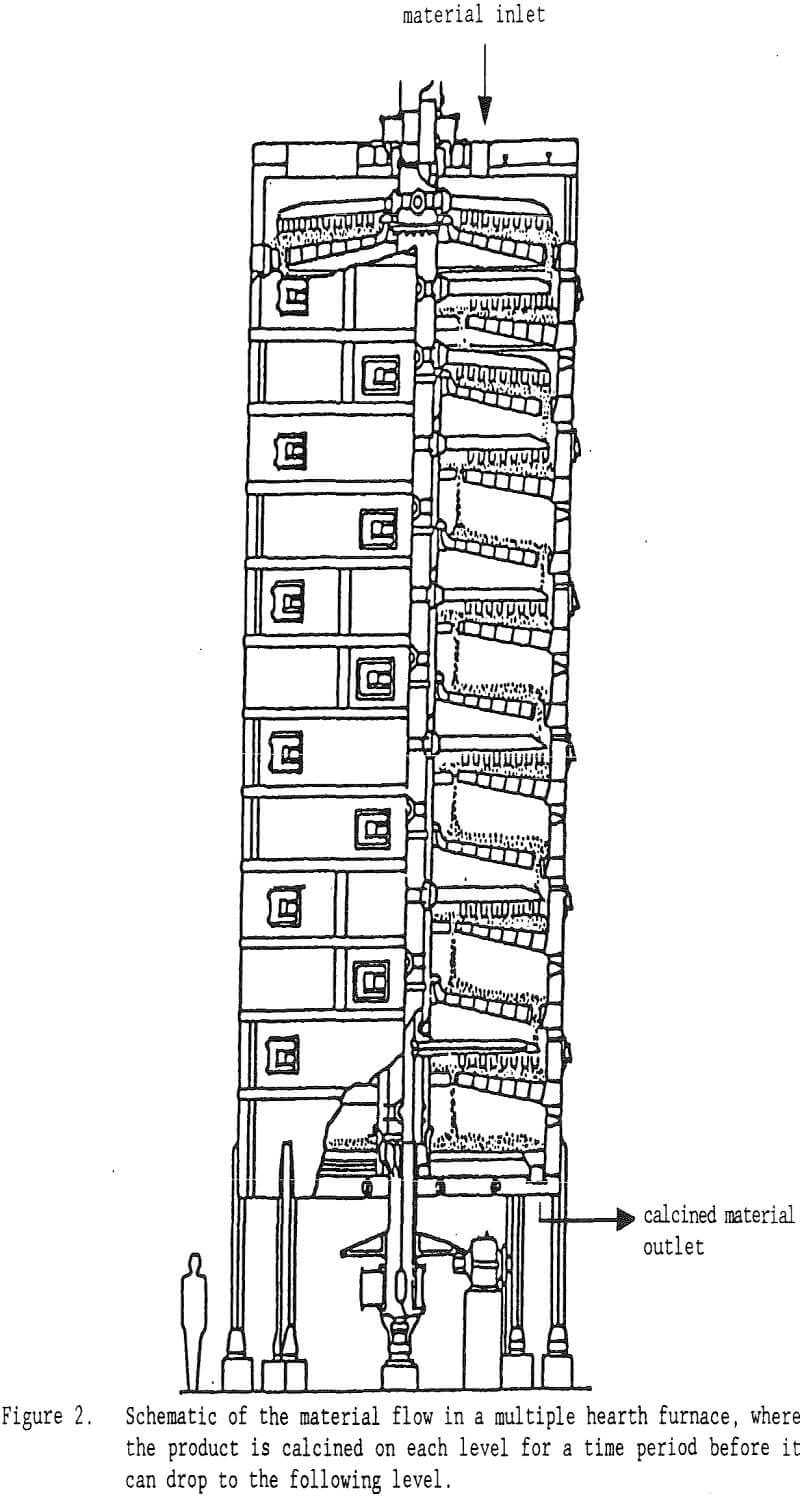

The multiple hearth furnace is used for the light density chrysotile transformation to ensure residence time and improve heat exchange. A thin bed of minerals is overturned, while heated at the required temperature for phase transformation on each level, before it is dropped to the next level. Eight levels of calcination were used with this type of furnace.

The development of industrial mineral occurs through a combination of interesting properties and specific applications. The transformation of serpentinite has led to two new industrial minerals that have very distinct properties. These minerals are: a synthetic olivine sand, and a light density powdered forsterite.

Jetmag and Magfill are used in foundries for molding and core sands because of their good packing ability coupled with little fines, no absorption, and very low thermal expansion. This ensures good surface finish of castings.