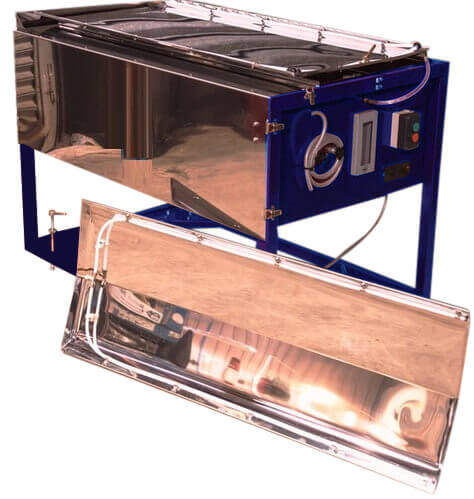

The superpanner is another device worked out by Professor Haultain for the accurate panning of small samples (see Fig. 59). This is a mechanized sichertrog or gold-panning horn. The pan is trough-shaped, about 30 in. long by 10 in. wide. The radius of curvature of the bottom diminishes from the lower end to the upper end. A peculiar-shaped cam imparts a bumping motion to the pan, which tends to progress the material toward the upper end. A controllable side motion combined with the wash water washes the surface particles to the lower end. There are seven adjustments readily made while in operation. It is a very sensitive apparatus, but as now developed, the technique of operation is quickly acquired. It is essentially a batch gravity concentrator. It will give valuable results on as small a quantity of material as 1 gram or will treat much larger amounts. Aided by a binocular microscope or the pyrex-glass method and the microscope, it will readily isolate and identify tellurides when occurring in the proportion of 1 part in 10 million. It will give a clean pyrite product or a clean tailings product. It will separate pyrite from arsenopyrite. It will make separations of extremely fine material down to 15 microns. It has been in the process of incubation for a great many years and was brought in as a useful tool when W. E. Johnston was doing his work on tellurides and was used most effectively by him, and its success is due very largely to his persistence and patience in the development stage.

The superpanner is used at for the following purposes:

- To determine accurately the assay of the pyrite in the cyanided mill products.

- To determine the quantity and nature of the undissolved free values in a cyanide tail.

- To analyze completely original ore samples, high-grade flotation concentrates, etc., separating the sample into the following parts:

(a) free metallic gold,

(b) free gold tellurides,

(c) free galena and altaite,

(d) pyrite, and

(e) gangue minerals - For preparing high-grade concentrates of the gold-bearing minerals for briquetting, polishing, and microscopic examination.

The panner may be used at all times for rough preliminary tests to determine the presence of free values and their nature or to determine an approximate pyrite assay, without sizing the panner feed. However, for all work on which metallurgical calculations are to be based, it is absolutely essential that the samples to be panned should be sized. It is the use in combination of the infrasizer and the superpanner that has made it possible to analyze completely any mill product. Otherwise, if an unsized material is panned, at best only the coarse pyrite is obtained, and often fine gold or tellurides are trapped with it, giving an erroneously high pyrite assay. The superpanner was particularly useful at the Lake Shore because it was realized early in the test work that the gold in the pyrite was not likely to be recovered by straight cyanidation and that the amount of gold tied up in the sulphide would have to be estimated in order to interpret test results correctly. The panner is by far the quickest and best known means of preparing clean pyrite free from gold and tellurides and gangue.

The following is the procedure used to determine the gold content in the pyrite in a cyanide tail: A gold-sulphur infrasizer analysis is first made on the cyanide tail. From this, the size distribution of the sulphur (and pyrite) can be calculated. As the ore contains only 1½ to 2 per cent pyrite, a flotation concentrate is made in the laboratory to save time in the panning, (NOTE. It has been proved that the assay of the pyrite in the flotation concentrate and flotation tail from a cyanide tail are the same assay per size, so that fact that the laboratory would make only an 80 to 85 per cent pyrite recovery will not affect the assay of the pyrite per size.) Generally, 12,000 to 15,000 grams of cyanide tail is used as feed to the cells to produce 200 to 250 grams of pyrite. If this flotation concentrate is known to contain much free values, time will be saved by thoroughly cyaniding it before sizing and panning. From each sized fraction, one or more clean pyrite samples are made for gold and sulphur assaying. An average superpanner operator can easily make pyrite concentrates which are 90 to 98 per cent pure. These assays are then corrected to correspond to 100 per cent pyrite. All the plus 14-micron fractions can be readily panned; the 10 to 14 can sometimes be satisfactorily panned. However, by plotting many Lake Shore pyrite results on a graph, a curve for the pyrite assays by fractions has been determined. Thus it is possible to determine graphically the assay of the pyrite in the 0 to 10 and 10 to 14 (if necessary). All these figures have been checked by calculations made in the routine mill work.