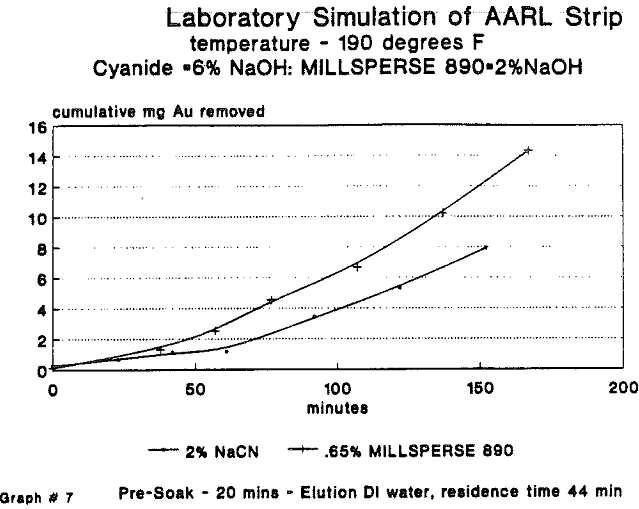

Stripping of gold and silver from carbon is effected by means of two main processes (AARL and ZADRA). The main rate-enhancing parameter in the stripping of gold and silver is temperature. A secondary rate-enhancing parameter is ionic strength. (1) Stripping is usually conducted within a solution containing sodium cyanide (0.1 – 0.5%) and caustic (1 – 3%).

Several different analogous chemistries were investigated, and it was found that both an aromatic carboxylated salt as well as a polycarboxylated polymer improved the distribution coefficient of the gold between the carbon and the solution.

The research work was conducted in two stages:

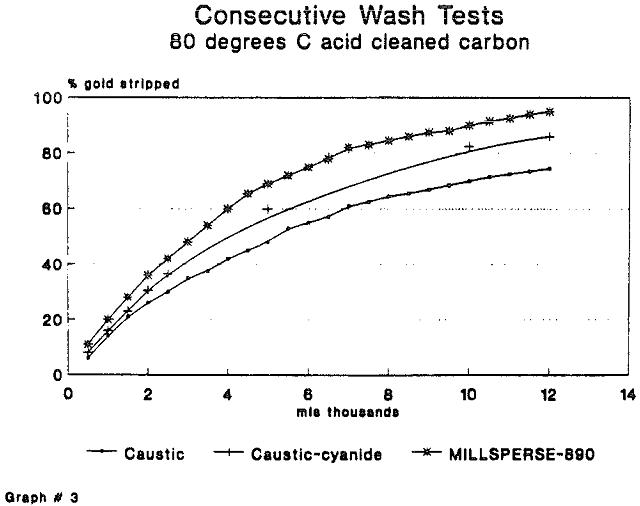

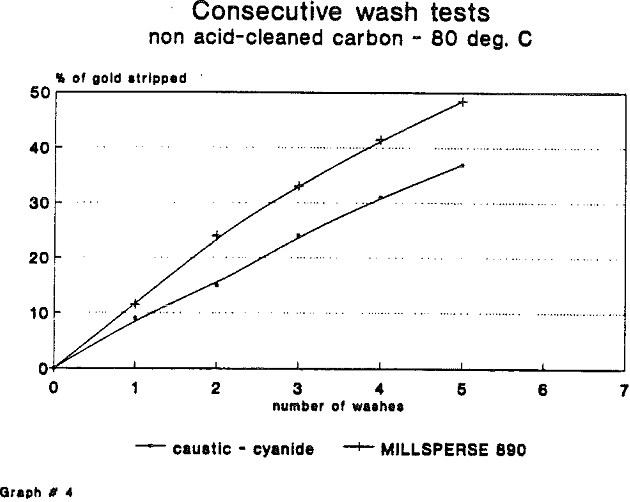

A) Consecutive wash tests.

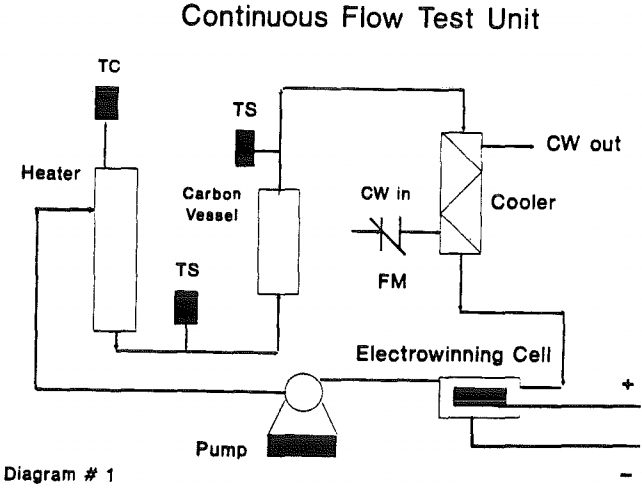

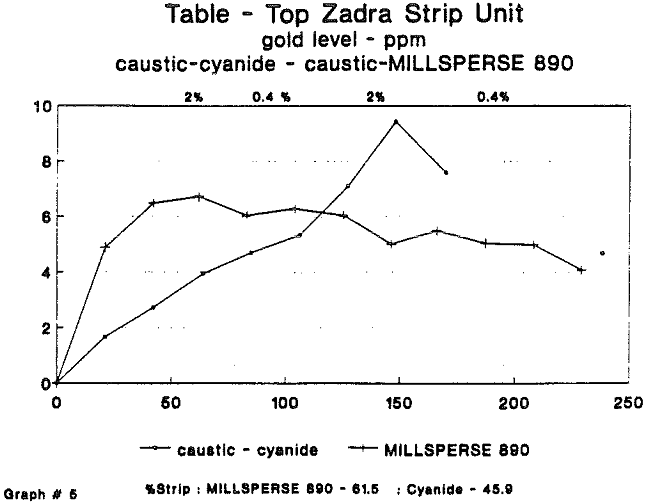

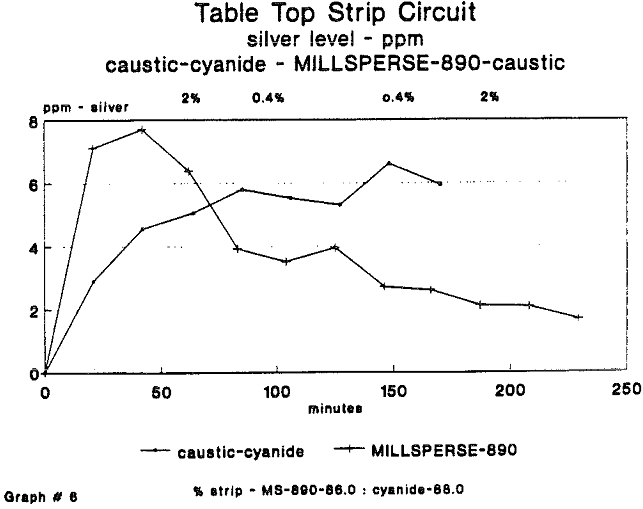

B) Table-top ZADRA type test unit.

Some of the chemistries that were investigated included benzoic acid, octanoic acid, polycarboxylic acid (various molecular weights), salicylic acid, polymaleic acid, acetic acid, terephthalic acid, 4, bi-phenyl carboxylic acid, phosphoric acid and stearic acid.

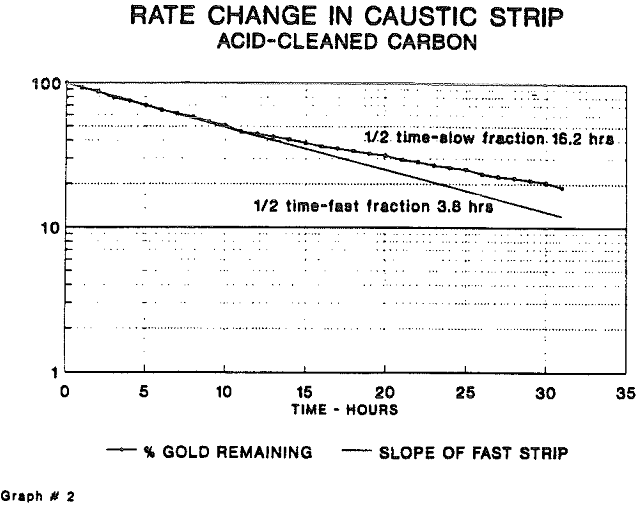

A number of test strips were run on all of the chemicals named above at various concentrations. This work was conducted on non acid-cleaned carbon at a temperature of 80 degrees C. The control in this preliminary work was a strip solution consisting of a 2% caustic solution.

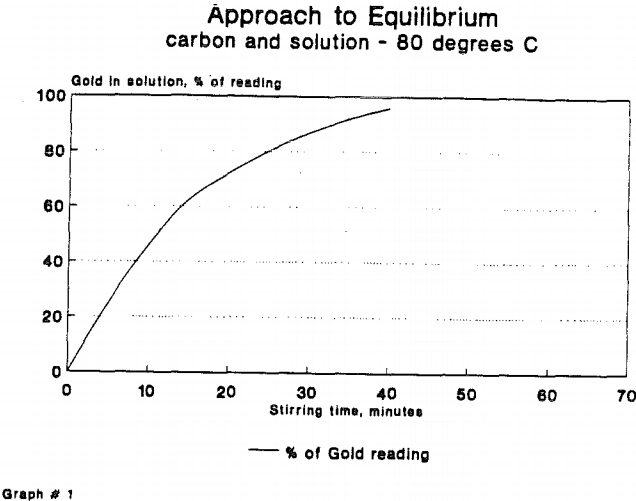

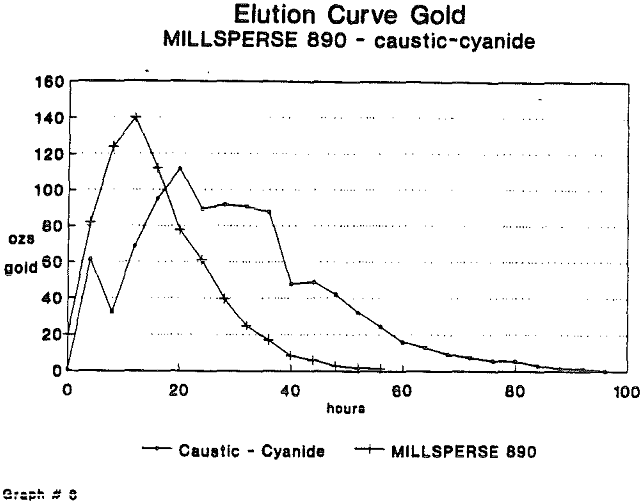

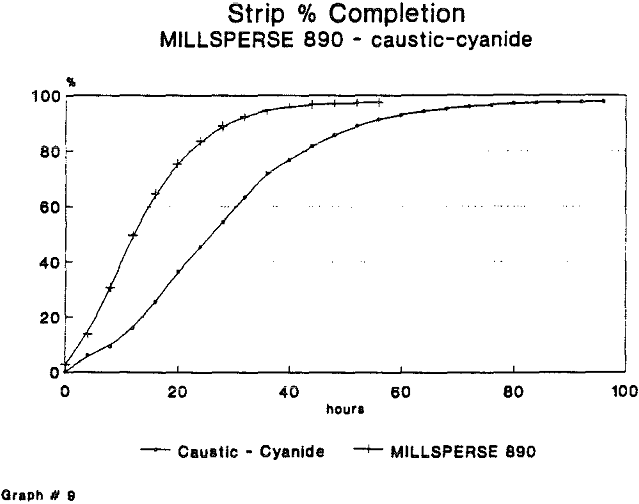

In order to compare one test strip run to another, a means of quantifying rate was required. Each gold assay result on the elution curve was converted to % of gold remaining on the carbon. The log of each of these fractions was then plotted against the volume of eluant solution used at each point.

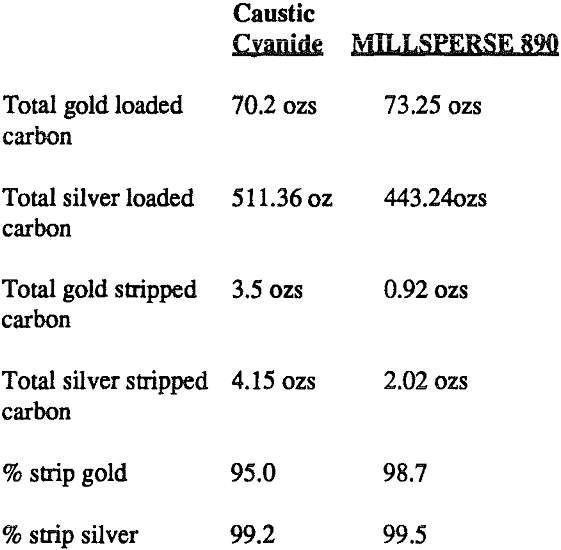

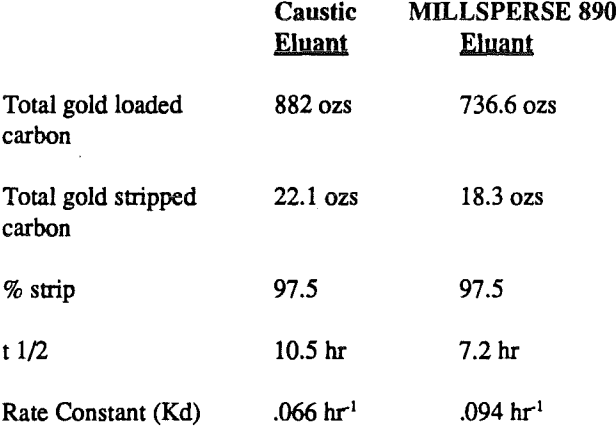

Two trials (atmospheric and pressure) have been successfully run with this new carbon eluant. The strip circuit for this trial is an atmospheric ZADRA type. It operates at a temperature of 200 degrees F. The carbon is acid cleaned before stripping. Present eluant consists of a 2% caustic solution. The preg solution is sent directly to electrowinning. Typical electrowinning voltage is approximately 3.5.

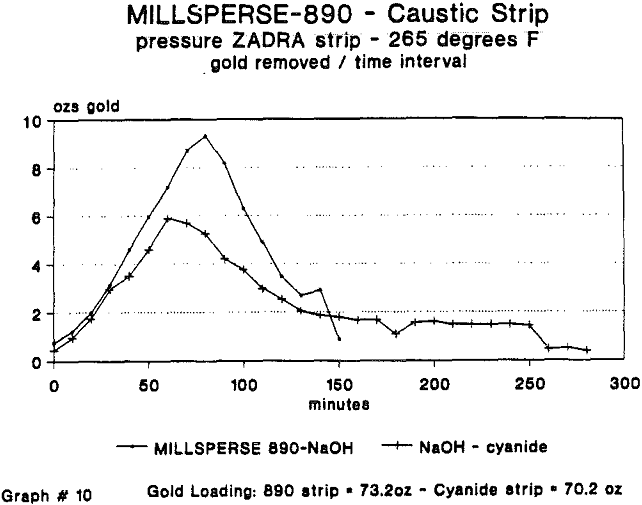

Pertinent Data

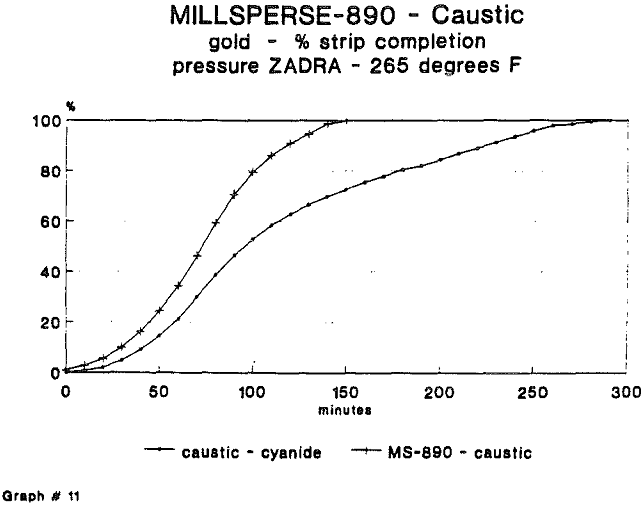

The circuit in which this trial was run is a pressure ZADRA circuit. The temperature of the preg effluent from the strip vessel is 260 degrees F. The batch of carbon used in this trial was not acid-cleaned. The control eluant solution is composed of 2% caustic and cyanide.