Table of Contents

In the Southwest a number of large steel chimneys discharge the gases from the copper smelting furnaces. Some of these chimneys show no deterioration after twenty years, others show serious deterioration after four years service.

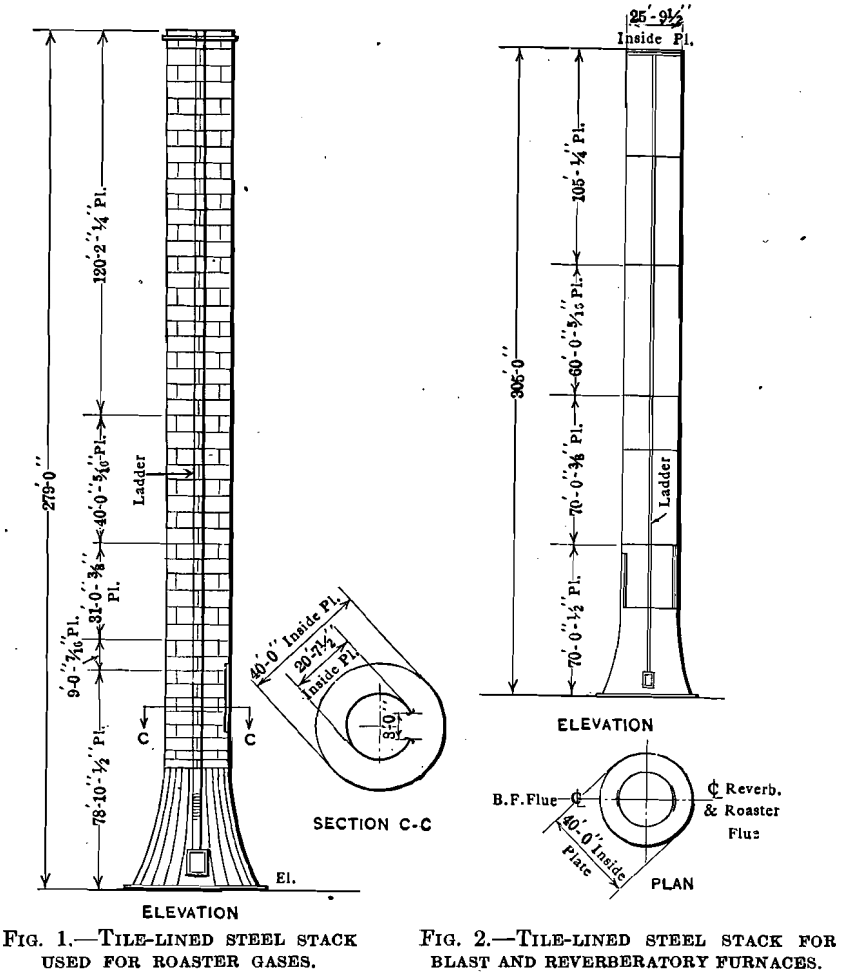

A steel stack 20 ft. 7½ in. (6.3 m.) in diameter by 279 ft. (85 m.) high, Fig. 1, used for roaster gases only at the Calumet & Arizona Mining Co.’s plant at Douglas, Ariz., was lined to the top of the bell, 40 ft. (12 m.) from the base, with common brick placed on end, lime and cement mortar being used. Above the bell, the stack was lined with 4 by 4 by 8 in. (10 by 10 by 20 cm.) building tile, placed on end, making a lining 4 in. thick. The tiles were supported on angle-iron rings, riveted to the inside of the chimney shell about 15 ft. apart.

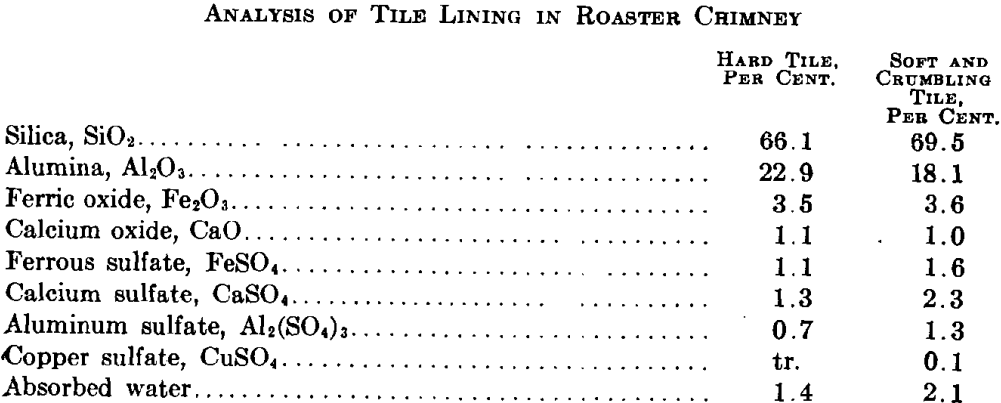

The chimney was put into use in the latter part of 1913. Four years later, considerable of the tile lining had fallen out of place and mixed with the flue dust at the bottom of the chimney. About a year later, several flattened and distorted sheets were noticed about 70 ft. below the top. An investigation showed that the thickness of these distorted sheets, which was originally ¼ in., had been reduced one half. One year later, or six years after the chimney went into use, several holes, a square foot and smaller in area, appeared near the flat spots mentioned. Soon afterwards, when the chimney was shut down for repairs, it was found that most of the tile lining for 125 ft. from the top had fallen out and that the steel shell was badly corroded; but where the lining remained in place the shell was undamaged. Many of the tile which had fallen out of place had become soft or flaky and crumbling, others were as hard as when placed. An analysis of the hard and soft tile is shown on p. 2. These tile were of a fireclay mixture, and were used instead of common brick on account of lower cost.

The steel forming the upper 125 ft. (38 m.) was replaced, and a 4¼-in- (11-cm.) lining of firebrick was laid from the bell to the top of the chimney. The brick were placed on end, wedges and keys being used. After each 8-in. course was set, keyed, and wedged tight, thin mortar —water, sodium silicate, and finely ground silica—was worked into the joints. The brick are supported on angle-iron rings, every 15 ft., in the same way as the tile.

While many common brick and tile can be boiled in sulfuric acid, without any signs of deterioration, they will often slowly disintegrate when exposed to gases from smelting-plant furnaces. In the case of three reverberatory furnace flues and two roaster dust chambers and flues where ordinary red building tile were used instead of brick, the reverberatory flues carrying the gases between the waste-heat boilers and the smoke stack, one flue had to be reconstructed within two years, one has been in operation five years, and the third seven years, without any apparent deterioration in the structure of the tile. The tile in both roaster dust chambers and flues have given trouble and a number of sections have been replaced or repaired. The rapid deterioration of the first flue was probably due to the cooler gases because fewer furnaces discharge into it than into the others.

When tile are exposed to the deleterious action of the gases, their thin walls gradually disintegrate and finally fail. Brick are more satisfactory for the walls of flues and dust chambers than tile. Brick exposed to low-temperature gases disintegrate in the same way, but the rate of disintegration is gradually reduced so that many years pass before the brick are injured sufficiently to cause them to fail.

Tile-Lined Stack for Blast and Reverberatory Furnaces

At the same plant, a steel chimney, 25 ft. 9½ in. (7.8 m.) in diameter by 305 ft. (92.9 m.) high, Fig. 2, lined with hollow building tile, has been in use since June, 1913. The lining is still in place and no deterioration of any part of the structure is apparent. This stack is used for discharging the gases from blast furnaces and reverberatory furnaces, which are hotter than the gases in the roaster stack.

Brick-Lined Blast-Furnace Stack

At Cananea, a steel chimney 19 ft. 9 in. (6 m.) in diameter by 170 ft. (51.8 m.) high was put into service in 1903 in connection with the blast furnaces; it is lined with common brick. The lining of the lower 85 ft. (25.9 m.) is 6 in. (15 cm.) thick, being made of blocks 2½ by 6 by 12 in.; the lining of the upper 85 ft. is 4½ in. thick, being made of blocks 2½ by 4½ by 12 in. All blocks are made radial to suit the circle in which they

are laid. This chimney has been cold a number of times for periods of from several days’ to a year’s duration, but there is no apparent deterioration.

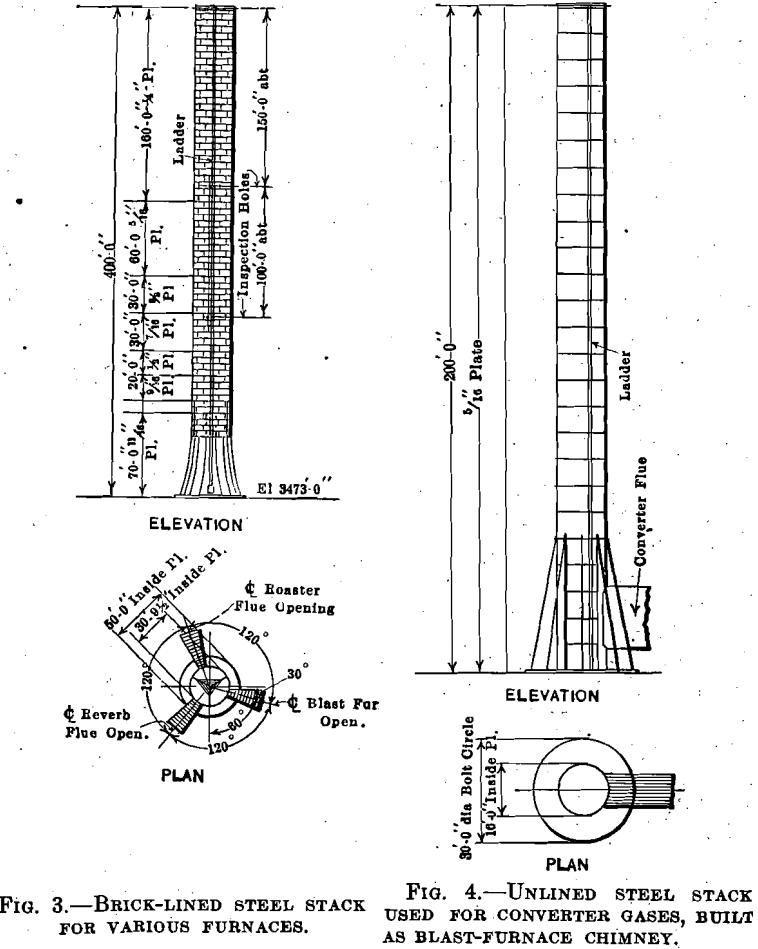

Brick-Lined Stack for Various Furnaces

At the United Verde Copper Co.’s smelting plant at Clarkdale, Ariz., a steel chimney 30 ft. 9½ in. (9.3 m.) in diameter and 400 ft. (121.9 m.) high, Fig. 3, was put into service in June, 1915. The gases from, the blast, roaster, and reverberatory furnaces and the converters pass through it. The 4½-in. brick lining is supported on angle iron rings 15 ft. apart. Recently ½-in. test holes, drilled in the steel shell at intervals all the way to the top, showed no signs of corrosion.

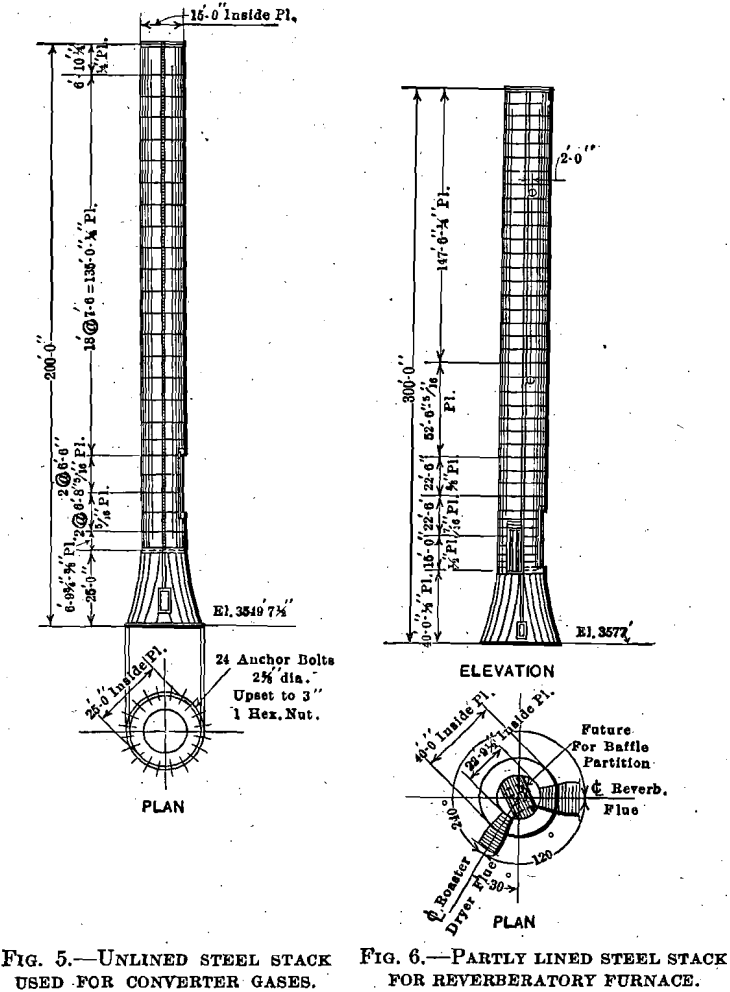

Unlined Stacks for Converter Gases

At the Calumet & Arizona plant at Douglas, there is a steel chimney, 15 ft. (4.5 m.) diameter by 200 ft. (60.9 m.) high, Fig. 4. It has been unlined since it was erected at the original plant of the company, in 1906, as a chimney for the blast furnaces. In the latter part of 1913, this plant was shut down, so the chimney was dismantled and re-erected at the new plant where it has served as the converter department chimney. It is still in apparently as good condition as when new.

At the International Smelting Co.’s plant, at Miami, a steel stack, 15 ft. diameter by 200 ft. high, Fig. 5, is used for discharging the gases from the converter department. It is unlined and has been in use since May, 1915, except during a six weeks’ strike in the rainy season. At present it shows no signs of deterioration.

Unlined Stacks for Blast Furnaces and Converters

At Morenci, Ariz., the Detroit Copper Co. put into operation, in September, 1899, an unlined steel stack, 13 ft. (3.9 m.) diameter by 165 ft. (50 m.) high, to discharge the gases from copper blast furnaces and converters. It has been cold during several periods on account of strikes. At the present time, the stack is in good condition, with the exception of the upper 12 ft., where it has commenced to deteriorate quite badly since the plant was shut down eight months ago.

At the Copper Queen smelting works in Douglas, an unlined steel chimney, 25 ft. (7.6 m.) in diameter by 260 ft. (79 m.) high, was put into service in June, 1904, to discharge the gases from the blast furnaces and converters. A recent investigation showed that the interior was coated with flue dust, about 2½ in. (6.35 cm.) thick, but that the steel is of its original thickness. The chimney has not been cold since 1906. The minimum temperature of the gases in this chimney is 325° F.

At the Old Dominion smelting plant in Globe, an unlined steel stack 14 ft. (4 m.) in diameter by 200 ft. (60.9 m.) high, has been in use since August, 1904, to carry the gases from the blast furnaces and converters. The plant has been shut down several times, once for six weeks during the rainy season, but the stack shows no deterioration.

Unlined Stacks for Reverberatory Furnaces

At the International Smelting Co.’s plant at Miami, Ariz., a steel chimney 22 ft. (6.7 m.) in diameter by 300 ft. (91 mi.) high, Fig. 6, discharges the gases from the reverberatory furnaces. When the chimney was built, it was thought that a lining would not be required but as the reverberatory furnaces have waste heat boilers installed between them and the flue leading to the chimney and as there was a possibility that the boilers might be by-passed at some time and the hot gases from the reverberatory furnaces allowed to go directly to the stack without much cooling, it was decided to line the lower 100 ft. In the bell, common red brick was used; above the bell common red building tile 4 in. thick was used. The chimney was put into use in May, 1915. In 1917 the plant was shut down, on account of a strike, for six weeks during the rainy season. About a year later, it was noticed that certain sheets had become distorted and an investigation showed that the steel sheets above the lining were seriously weakened from corrosion. A temporary repair was made by reinforcing the chimney for 75 ft. with an outer steel shell. As corrosion is continuing, a new radial brick-tile chimney is being built to replace the steel chimney.

A steel chimney at the reverberatory furnace plant of the Gananea Consolidated Copper Co. 12 ft. (3.6 m.) in diameter by 171 ft. (52 m.) high, had a 9½-in. (24-cm.) firebrick lining in the lower half and a 4½- in. (12-cm.) firebrick lining in the upper half. This chimney was put into service in, 1902, and after a year’s service as a blast-furnace smokestack, it was unused until 1908, when it was put into service as a reverberatory furnace stack. In 1910, the reverberatory furnaces needed more draft so the brick lining of the chimney was removed, as it was thought that reverberatory furnace gases would not injure the steel. In 1917, it was necessary to renew the upper 75 ft. of the stack, but the lower part of the stack had deteriorated but little. The stack was not relined.

Conclusion

Based only on the examples cited, the following conclusions may be drawn: Unlined steel chimneys have not given satisfactory service when used for roaster or reverberatory furnaces. Unlined steel chimneys have given satisfactory service for long periods when used for blast furnace and converter gases.

Building tile have proved unsatisfactory for chimney linings or for the construction of walls for flues and dust chambers where exposed to roaster furnace gases or cool reverberatory furnace gases.

These conclusions apply to the ordinary conditions in copper smelting plants, where waste-heat boilers are used in connection with reverberatory furnaces, and where no particular effort is made to maintain the gases at a high temperature in the flues, dust chambers, and stacks.