The use of steam-stamps in the crushing of ore for the purpose of amalgamation has been very limited, and little has been written on the subject. As the writer has been operating a mill of this kind during the past year, it is possible that he may be able to present a few points in regard to mill-practice in this line which will be of interest.

The mill herein referred to contains two Tremain steam- stamps, a more detailed description of which will be given below. A bond and lease had been taken on a property on Cross mountain, Gunnison county, Colo., and the parties operating wished to prospect it thoroughly and did not wish to ship out the ore, owing to high freight-rates. They looked around to find some mill that would answer the purpose and not be too expensive. The steam-stamp in question was finally decided on, and the writer was employed to erect and operate it.

The economy of construction was demonstrated at the outset. The stamps were dropping within ten days from the time that the machinery was unloaded on the ground. A large portion of this period was consumed in waiting for supplies and fittings which should have been on the ground at the same time with the machinery.

Ore

The ore to be treated was a mixture of white, porous quartz, with the decomposed and undecomposed oxides of iron and manganese in varying proportions, from the pure white quartz to solid pieces of the oxides. It appeared to be the product of replacement in a soft dolomite at or near the line of contact with a dike of porphyry. On careful examination with the aid of a microscope it was found that the gold was in the form of an extremely thin film over the surfaces of the quartz, making only a bronzy-yellow coating, quite readily distinguished from the film of iron oxide, which was also present.

Mill

The mill was constructed on the usual plan, with the ore-bin above and against the hill, which was cut into for the main building. The bin was of about 20 tons’ capacity. No rock-breakers were used, but the larger pieces of ore were broken by hand to a size that would pass through a 3-inch ring. The ore passed into a Challenge ore-feeder, from which it was fed into the mortar.

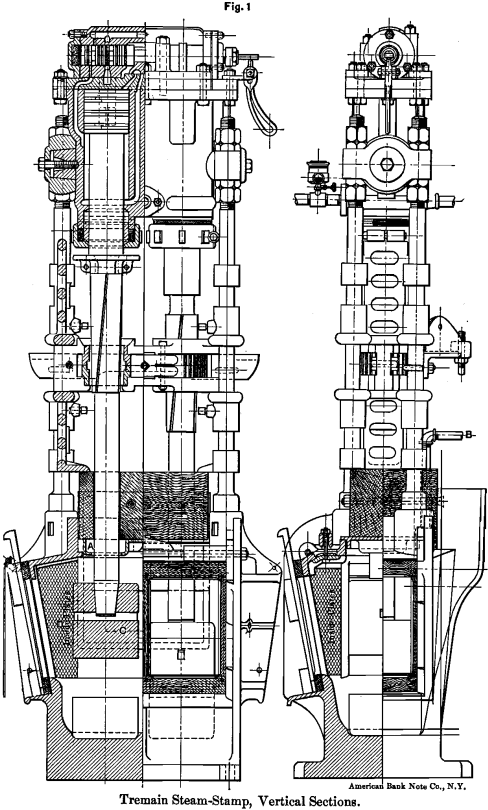

For the benefit of those not familiar with the steam-stamp under discussion, although some may be, a description will be given so far as to make clear any reference made hereafter to any part.

The sections of the stamp shown in Fig. 1 will give some idea of its mechanical construction.

The mortar is 12 by 20 inches in size at the inside of the lip of the discharge, and 14 by 24 inches at the outer edge of the lip. Screens are placed on three sides, the front and the two ends, giving 384 square inches of screen-surface. The depth from the discharge to the bottom of the mortar, including the recess made to receive the die, is 7 inches. The die, being 5 inches high, leaves only 2 inches issue for the pulp. This was increased to 6 inches by the addition of a 4-inch “ chuck- block ” carrying a copper plate on the inside. This reduced the screen-area to 256 square inches, but did not materially decrease the capacity.

The stamp comprises the piston, stem and stamp-head, and, when newly shod, weighs 300 pounds. The steam lifts the stamp by a 6-inch piston-head, the lower area of which is reduced by the 4-inch stem, which extends downward from it, leaving, as a lifting-area an annular surface 1 inch wide at the outer edge of the head.

When the piston is raised to a certain point, connection is made between the two ends of the cylinder. The upper surface of the piston-head being greater, the stamp is forced down with a force proportionate to the surfaces, together with its weight, giving a blow of about the same force as that of a 1000-pound stamp. The length of the drop varies from 5 to 8 inches, according to the amount of wear on the shoe and die. Provision is made for the operating of the automatic feeder, by cutting a recess in and around the stem near the steam-chest, into which a collar is bolted which actuates the feeder-arm. Reference will be made to this later on. The shoes are cast similar in form to the gravity stamp-head, with the exception of the recess

in the lower end, to receive the shank of the shoe. They are fitted to the stem by placing short feathers of sheet brass around the sides of the hole in the upper end of the shoe, placing it on the die in the battery, in its proper position, and allowing the stem to drop into it. The entire stamp is raised with a bar and allowed to drop several times until secured. Steam is turned on slowly and the stem driven to place by a few blows, when it is ready for regular work. There is a system of ratchets and pawls which revolve the stamp on the upward stroke, leaving it to fall in a direct line. There is, on an average, 1 complete revolution to about 15 strokes.

The shoes and dies wear very evenly and smoothly, and with the ore in question wore about ½-inch each per 100 tons crushed.

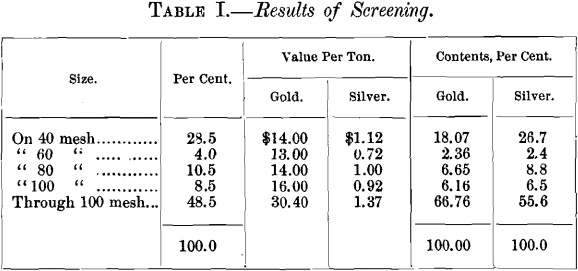

Thirty-mesh screens were used at first, but on experimenting, it was decided to use 20-mesh instead. This gave a product of the following description, as to proportions of size and values. The crushing is evidently fine enough, and could be coarser but for the fact that the tailings were to be subjected to a subsequent treatment, which required the size to be no coarser.

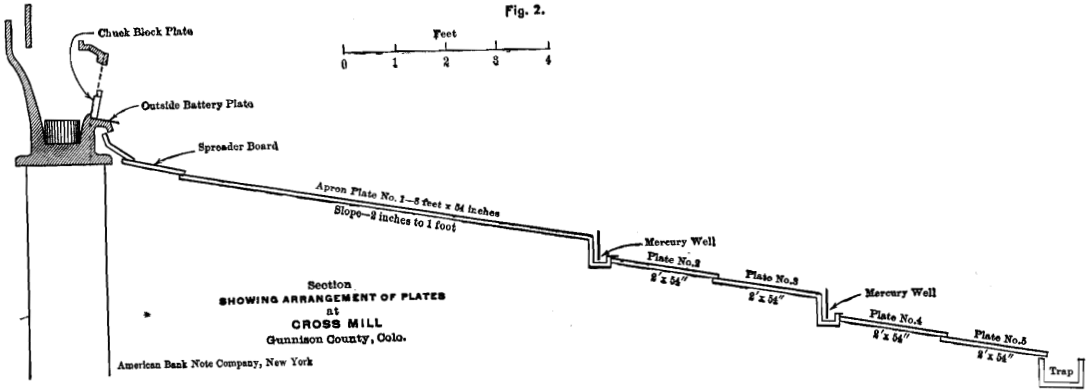

The mortar, as originally designed, was intended to have four amalgamated copper-plates inside. These were to be placed in the corners and were very small. The splash was so great that they scoured badly. They were covered with wire-screen cloth, and the results were greatly improved, but they were finally abandoned entirely, and the copper-plates on the “ chuck-blocks ” were substituted, but these were not satisfactory. Very little amalgamation is accomplished in the mortar; fully 95 per cent, of the amalgam recovered comes from the outside plates. Of these there are 8, of which 3 are attached to the mortar, one just below each screen. These are cleaned up but once a week. There are 5 apron-plates, 4½ feet wide, and 16 feet in aggregate length.

The first is 8 feet long; and the second, third, fourth and fifth are each 2 feet long, and are arranged as shown in Fig. 2. This arrangement, in this case, is very effective, as the mercury in the two wells can be kept active by the addition of sodium amalgam, preventing in a large degree the loss of quicksilver “ sickened ” by the oxides in the ore. By this method the loss of mercury was reduced ½, or from 2 ounces to 1 ounce per ton of ore treated.

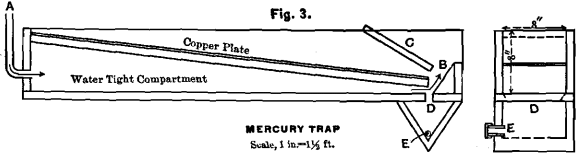

Owing to the fact that the proportion of heavy oxides was very great, sometimes amounting to 60 or 70 per cent., it was quite impossible to use the common forms of traps to recover mercury, and two forms were finally adopted which proved quite satisfactory. One was in the form of a “ clean-up pan,” which was arranged to be continuous in feed and discharge, and constantly stirred. This was used outside of the mill. The other was of the form shown in Fig. 3.

This was effective and convenient, saving considerable “ floured ” and “ sickened ” mercury. It is a modified form of the Spitzlutte, having a copper-plate on the slope on which the pulp falls. In the figure A is an inlet-pipe to supply water for the upward current at B. C is a board set in across the trap to prevent surface-currents. D is a V-shaped trough across the bottom of the trap to receive the mercury and the heaviest sands. E is an opening into the trough at its point, into which is screwed a short nipple, covered with a cap. When it is necessary to clean the trough, the cap is taken off from the nipple and a piece of pipe which fits closely inside the nipple is inserted and worked in and out, cleaning the entire length of trough. The copper-plate on the sloping bottom of the trap worked well, but it was necessary to clean it often, owing to filming by the oxide.

Wood

About 1/10 of a cord of dry spruce and pine was used per hour, or about 2/10 cord per ton of ore. This would indicate about 12 H. P. as the power required to operate the stamps. This could be greatly reduced by covering the boiler with a brick casing,

Capacity

The capacity, of course, varied according to the nature of the ore. Sometimes it amounted to 8/10 of a ton per hour, where the ore was soft and decomposed. At other times it was only 4/10 of a ton per hour, when the ore was principally quartz. The average was 12 tons per 24 hours.

Water

The apron-plates were at first set on a slope of 1½ inches to the foot, and, owing to the large amount of iron present, it was necessary at times to use as much as 3000 gallons of water per ton of ore. On setting the plates on a slope of 2 inches to the foot, this was reduced to 1000 or 1200 gallons per ton. The water supply is furnished by a 1¼-inch pipe line about 500 feet long, with a head of 30 feet, which is more than sufficient for all needs.

Considerable objection has been offered by some based on the alleged liability of oil or oily water finding its way to the plates from the steam-chest. At first, this did annoy us; but by keeping the packing of the piston in good condition, it was almost entirely avoided. As a precautionary measure, we substituted for the collar or flange attached to the stem to actuate the feeder-arm, as before explained, castings of similar form, only with the addition of a rim around the edge to form a cup. This cup was of sufficient size to extend out from the stem the same distance as did the tightening-rings of the steam-chest, so that any drip would fall into it. This was filled with cloth, which would absorb the drip as it fell, and was occasionally sprinkled with soap shavings or pearline, which emulsified the oil carried down. Graphite lubricator, manufactured by The Joseph Dixon Co., will probably soon be experimented with, and the results will be reported. A circumstance may be mentioned in this connection which may be of interest. At first, lye or caustic potash was used to destroy the oil, and a greenish scum would form on the plates which it was impossible to keep off. On entering the mill one day, a faint odor of ammonia was detected, and the idea suggested itself at once that there might be sufficient iron held in solution by the battery water, dissolved from the ore, to be acted upon by the ammonia generated by the chemical combination of the sal-ammoniac (used to clean the plates occasionally) with the caustic potash, and be precipitated as ferrous hydrate, Fe(OH)2, forming the scum mentioned. Acting on this suggestion, samples of the water were filtered off from the tailings and treated with NH4OH. The hydrate was precipitated in considerable quantity. As a check, other samples of the water were treated with K4FeCy6, and, after standing a few hours, the blue coloration was very strong. The use of lye was discontinued, and the scum disappeared.

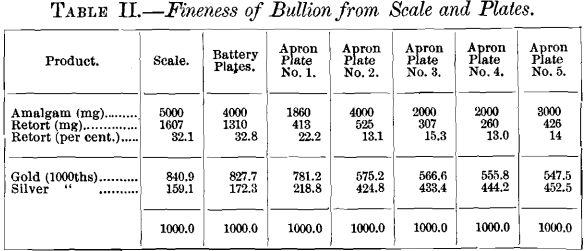

After about 400 tons of ore had been crushed, a scale was formed on the large apron-plate (No. 1) composed of hard amalgam, making the plate work unevenly. This scale was removed, and the value of it was found to represent about 10 per cent, of the entire value of amalgam recovered from the plate, or about $200, or 50 cents per ton of ore treated. Tests were made to determine the fineness in gold and silver of the bullion produced from this scale, as well as from the amalgam from the several plates, taking the three outside battery-plates as one.

The results were as follows :

The bullion was refined directly from the retort of the different samples, as the proportion existing between the gold and silver was all that was sought. The results show that the gold fineness decreases as distance is gained from the battery; also that the proportion of bullion to the amalgam also decreases in the same direction. The tool used to remove the scale from the plate was a common putty-knife, having the blade cut off to about one-half its length, and dressed with a file to have a slight bevel. This edge was further dressed on an oil-stone, so that it would loosen the scale without “ scraping ” so as to expose the copper. The plate was left in excellent condition, and, after a few hours, was perfectly normal.

After crushing 200 tons, the guide-blocks, set in the top of the mortar, were considerably worn, especially at the front of the stem. Strips of old rubber belting were inserted in these openings to keep the stems in place, and were found to work admirably, obviating the necessity of putting in new guide-blocks. These strips had to he renewed about every two weeks.

A number of tests were made to determine the percentage of possible amalgamation, which was found to range from 48 to 60 per cent., averaging 50 per cent. In actual practice, the percentage ranged from 40 to 55 per cent., averaging 48 per cent. It is safe to say, therefore, that the amalgamation was practically complete.

It would seem that the field of usefulness of the steam-stamp in connection with amalgamation is bound to increase in proportion as it becomes better known.